| Quantity | 3+ units | 10+ units | 30+ units | 50+ units | More |

|---|---|---|---|---|---|

| Price /Unit | $91.80 | $89.92 | $87.11 | $83.37 | Contact US |

M1000 Automatic Tape Dispenser 20-999mm Tape Cutter AC110V/220V with 75mm/32mm/25mm Roller Kit

$104.71

M1000 Automatic Tape Dispenser 20-999mm Tape Cutter AC110V/220V with 75mm/32mm/25mm Roller Kit

$104.71

ZCUT-9 Automatic Tape Dispenser Automatic Tape Cutter (with Silicone Tape Output Wheel) for 2 Rolls

$91.66

ZCUT-9 Automatic Tape Dispenser Automatic Tape Cutter (with Silicone Tape Output Wheel) for 2 Rolls

$91.66

ZCUT-9 Automatic Tape Dispenser Automatic Tape Cutter (w/ Plastic Tape Output Wheel) for 2 Rolls

$88.74

ZCUT-9 Automatic Tape Dispenser Automatic Tape Cutter (w/ Plastic Tape Output Wheel) for 2 Rolls

$88.74

1212C-2502 (90A) Original DC Motor Controller w/ CAN Port for EPT12-EZ EP Lithium Pallet Trucks

1212C-2502 (90A) Version:

1212C-2502 (90A) motor speed controller is designed with CAN port. It is suitable for EP lithium battery pallet trucks (EP 15ET2 lithium battery series with 60 version program)/EPT12-EZ. Conventional pallet jacks use 80 version program, while lithium ones use 60 version program. If devices for Mitsubishi are used, you need to input password. This model is also suitable for Linde ML10, 12ES/Linde ML12/Linde EST and TCM15ET.

Overview:

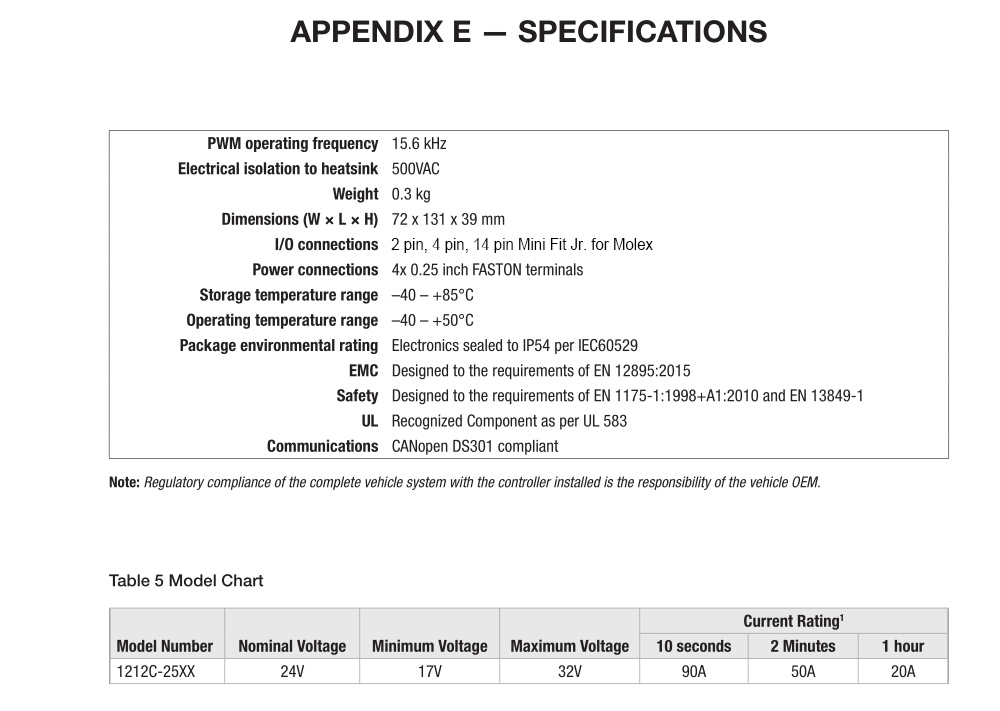

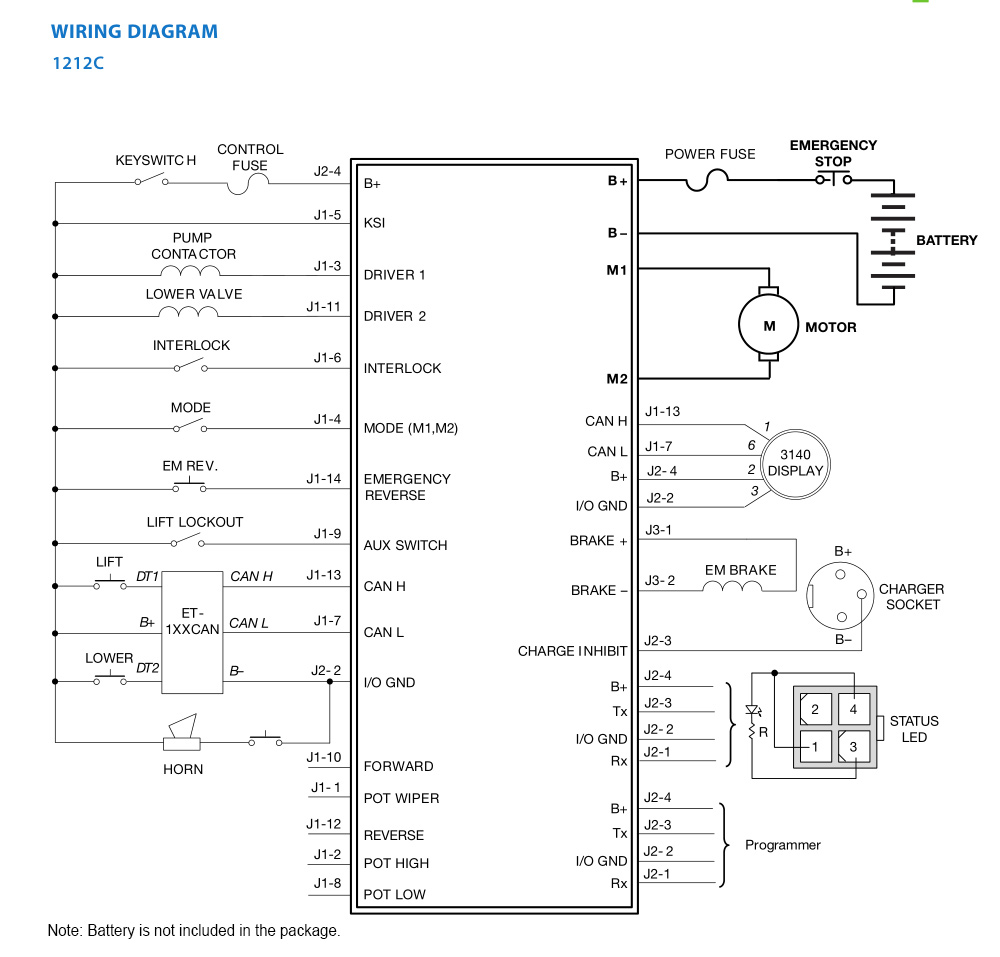

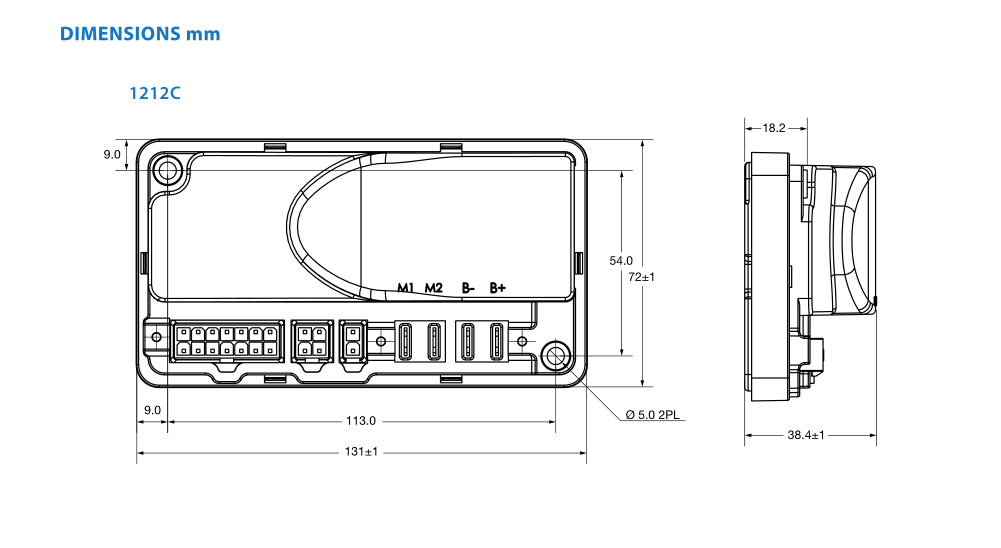

The 1212C motor speed controller provides efficient control of permanent magnet drive motors for battery-powered industrial vehicles. The 1212C is optimized for use on light-duty Class III pallet trucks, floor care machines such as sweepers and scrubbers, and similar industrial vehicles. However, the controller's flexible programmability means the 1212C can be configured for any low power permanent magnet motor application. You can use an original programming device for Curtis to configure the 1212C. Original programming devices for Curtis also provide monitoring and diagnostic capabilities.

The 1212C complies with CANopen DS 301. The controller's object dictionary includes all parameters.

In addition, the 1212C provides pre-configured PDOs for CAN bus communications with a CAN tiller and a battery monitoring system (BMS).

Features of 1212C Controller:

Smooth and Secure Control

• Maintains precise speed over varied terrain, obstacles, curbs, and ramps.

• Linear cutback of current ensures smooth control, with no sudden loss of power during under-voltage or over-temperature.

• Proprietary algorithms help prevent gearbox wear while providing smooth starts and reversals.

• Charger inhibit input prevents driving while charger is attached.

• Key Off Decel function ensures a smooth "brake to stop" when the key is turned off while driving or when a fault occurs that requires the vehicle to stop.

• Anti-Rollback and Anti-Roll Forward functions provide safe vehicle control on hills and ramps.

• Boost Current function provides superior performance with transient loads such as starting on a hill, crossing thresholds, climbing obstacles, etc.

Easy Installation and Setup

• Industry standard footprint, mounting centers, and wiring allows drop-in replacement of other controllers.

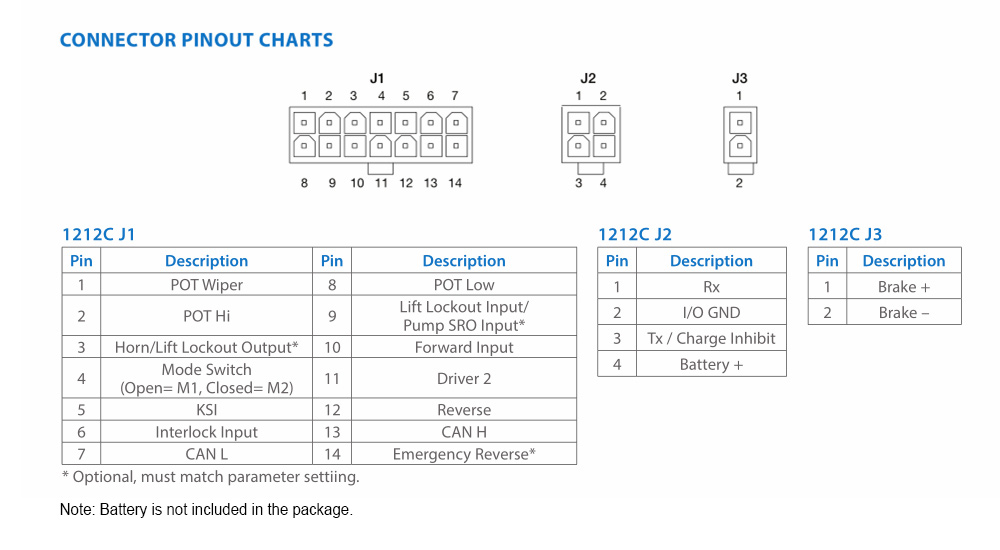

• Industry standard Mini-Fit Jr. For Molex and FASTON terminals.

• The controller is programmable with an original programming device for Curtis or can be supplied pre-programmed.

• Supports voltage, 3-wire resistance, CAN, single ended, and wigwag throttles.

Safety and Reliability

• High RF immunity prevents speed variation and shutdowns in noisy RF environments.

• Controller power circuits and microprocessor software are continuously monitored for proper operation.

• On power-up, the system automatically checks the throttle, brake, and associated wiring, and disables driving if a fault is found.

• Emergency reverse with belly button switch input.

• Meets or complies with relevant US and international regulations. For details, see Specifications.

CAN Features

• Complies with CANopen DS 301.

• Predefined PDOs for communicating with a CAN tiller and a battery monitoring system (BMS).

Additional Features

• Automatic compensation for changes in motor condition ensures optimum drive performance at all times.

• Two programmable speed modes.

• Battery Discharge Indicator (BDI) output.

• Adjustable brake hold voltage reduces heating of the brake coil.

• Motor temperature sensor input.

Package Included:

• 1 x Motor Speed Controller

Note:

• Battery is not included in the package.

Packaging Details:

• G.W.: 0.4kg