| Quantity | 3+ units | 10+ units | 30+ units | 50+ units | More |

|---|---|---|---|---|---|

| Price /Unit | $403.87 | $395.63 | $383.26 | $366.78 | Contact US |

EMD600W Buck MPPT Solar Charging Controller 10V-30V Output Voltage Adjustable Controller with LCD Display IP65 Waterproof

$70.57

EMD600W Buck MPPT Solar Charging Controller 10V-30V Output Voltage Adjustable Controller with LCD Display IP65 Waterproof

$70.57

1000W High Efficient Anti-reverse Solar Inverter MPPT Reflux Controller WiFi Cloud Monitoring Support APP Remote Control

$153.20

1000W High Efficient Anti-reverse Solar Inverter MPPT Reflux Controller WiFi Cloud Monitoring Support APP Remote Control

$153.20

800W High Efficient Anti-reverse Solar Inverter MPPT Reflux Controller WiFi Cloud Monitoring Support APP Remote Control

$147.37

800W High Efficient Anti-reverse Solar Inverter MPPT Reflux Controller WiFi Cloud Monitoring Support APP Remote Control

$147.37

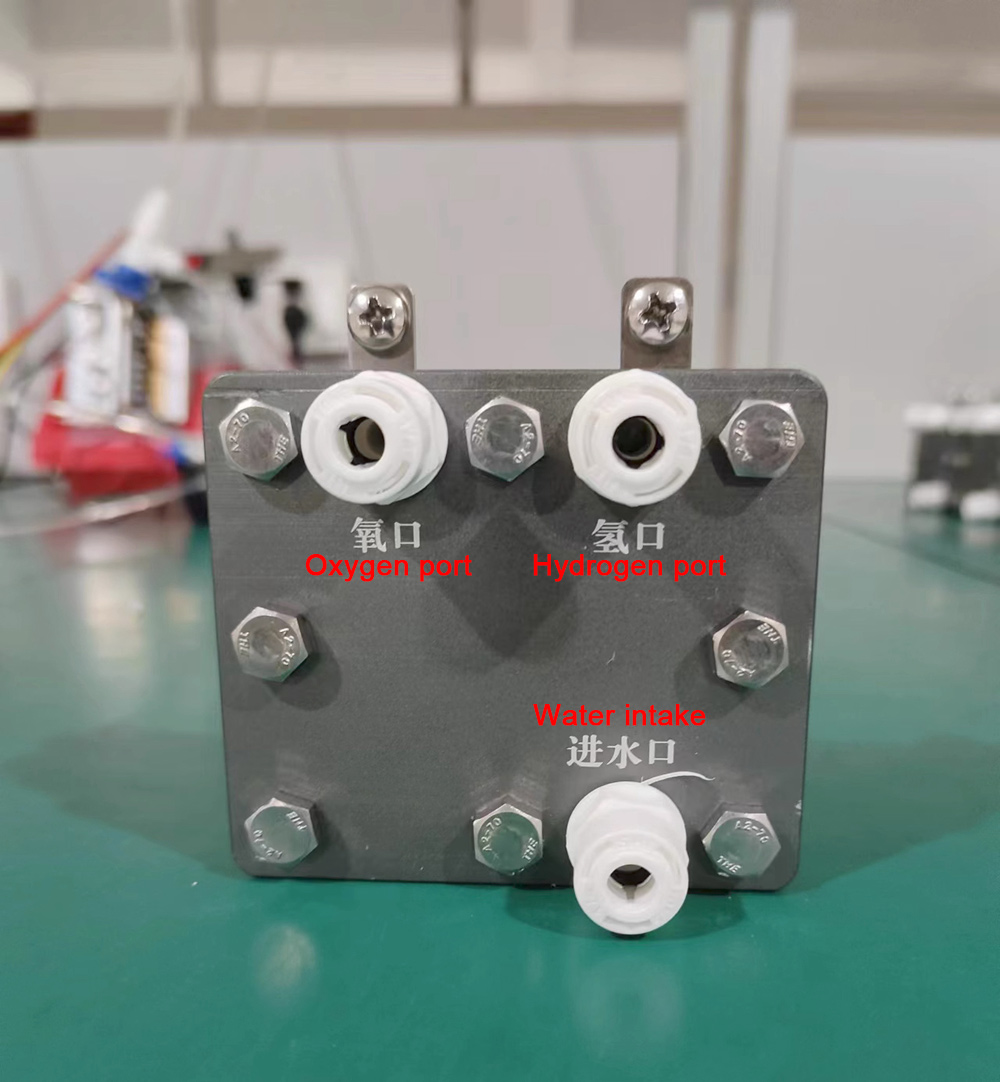

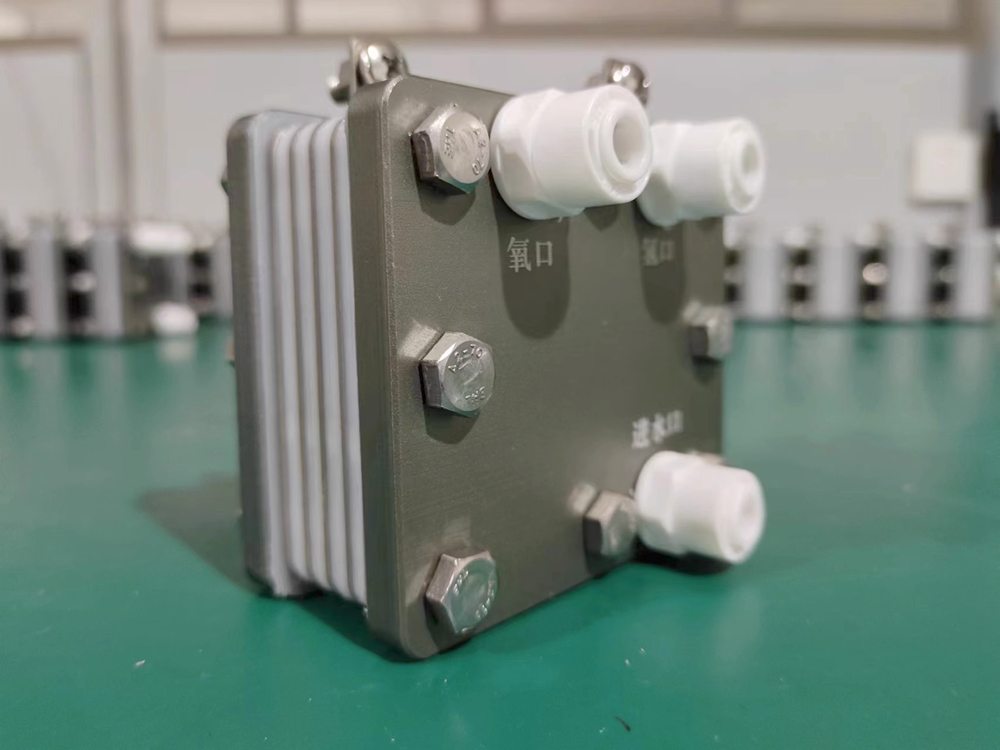

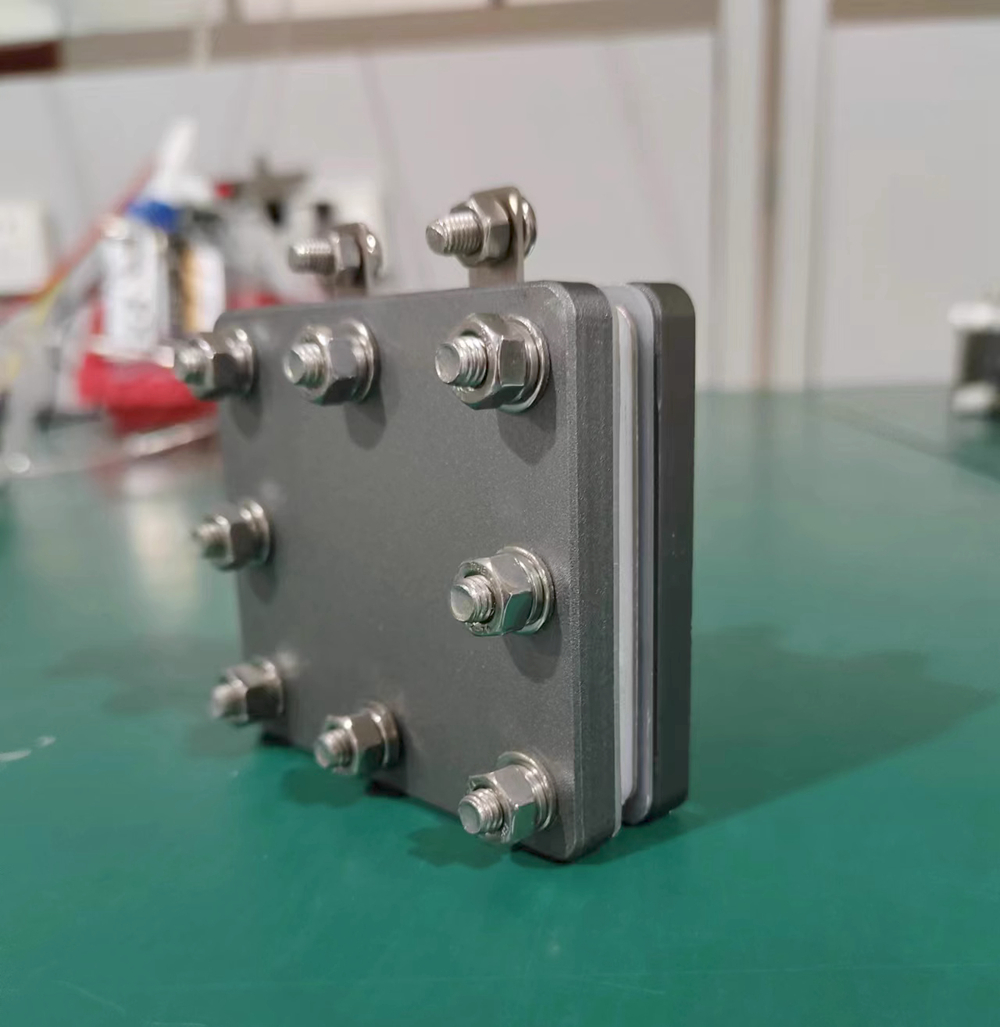

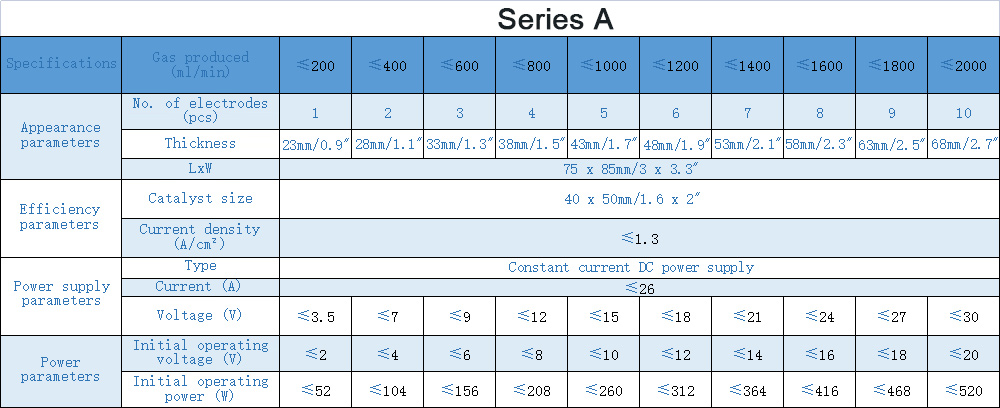

1400ml/min PEM Electrolyzer for Hydrogen Oxygen Hydrogen Generator Hydrogen Rich Water Generator

Features:

- Series A electrolyzer

- 26A rated current

- Small and sophisticated

- Stable gas production performance

Package Included:

- 1 x Electrolyzer

Attention:

-

Please operate this device strictly according to the instructions for

use. If you have any questions, please consult customer service.

Warranty and Disclaimer:

Under

normal use conditions, the warranty period of the product is 1 year,

starting from the time the electrolyzer leaves the factory.

The following conditions are not covered by the warranty:

1. Causes of circuits and control systems themselves, failure of other electronic components, etc.

2. Substandard water quality (e.g. mineral water, tap water or other liquids is used).

3. Ion exchange resin is not used.

4.

Operating the equipment in the event of water shortage (including dry

burning caused by the return of oxygen from the water inlet due to

unreasonable system design).

5. The power supply of the electrolyzer

is unstable and mismatched (for example, the current fluctuation

amplitude of the power supply is large: the fluctuation amplitude of the

current under actual working conditions is large, far exceeding the

rated current, and the electrolyzer will be seriously damaged).

6. The electrolyzer is connected to the positive and negative poles of the power supply reversely, resulting in burning.

7. Artificial disassembly and reassembly and its performance cannot be restored.

8. Other man-made and accidental damage or sabotage.

Instructions for use:

I. Product Design:

1.

Hydrogen products should be designed with a constant current power

supply that matches the voltage and current parameters of the

electrolyzer, otherwise they will cause damage to the electrolyzer or

the performance is not up to standard;

2. When the product is

designed, the height difference between the outlet of water tank and the

inlet of the electrolyzer should be greater than 10cm/3.9"; Or equipped

with a circulating water pump. When setting the circulating water pump,

there is no requirement for the height difference between the outlet of

the water tank and the inlet of the electrolyzer;

3. The operating

efficiency of the electrolyzer has a high correlation with the working

temperature. Frequent low temperature start-up will cause certain damage

to the electrolyzer, so the starting temperature should be fully

considered in the product design. Solving this problem requires

optimization in product design. On the one hand, the supply current

output at power supply start-up is controlled by a built-in program. The

output current gradually rises and finally stabilizes at the rated

operating current (the parameters should be consistent with the relevant

model). During this period, the working voltage does not exceed the

rated voltage; On the other hand, an automatic instantaneous heating

module or water tank heating module should be set between the outlet of

the water tank and the inlet of the electrolyzer to ensure that the

water temperature flowing into the electrolyzer is not less than 25°C;

4.

In order to ensure the long-term stable operation of the electrolyzer,

it is recommended to equip the product with an ion exchange resin

filtration device when designing. It can be set between the outlet of

the water tank and the inlet of the electrolyzer to ensure that the

electrolyzed water meets the use standard;

5. If the electrolyzer

reuses the circulating water from the oxygen port, it is recommended to

use the circulating water after ion exchange resin treatment

(conductivity< 5uS/cm). It is recommended to add an ion exchange

resin filter;

6. The internal space should be reasonably designed

when designing the product, especially there is enough space around the

electrolyzer, and the appropriate flow channel design should designed to

ensure normal air flow to achieve a good heat dissipation effect;

7.

The size of the water tank should correspond to the technical data

table. Level control and alarm devices should be set in the water tank

to ensure that the water storage is above the minimum liquid level

(refer to the technical data table for specific values).

II. Product Assembly Process:

1.

In the process of product assembly, it is necessary to fully understand

the working principle and characteristics of the electrolyzer, prevent

the joints and nozzles of the electrolyzer from being contaminated by

other substances, and keep your assembly workshop clean;

2. When

connecting the circuit system, carefully distinguish the positive and

negative electrodes of the electrolyzer to prevent reverse connection,

because reverse connection will cause the electrolyzer to be burned;

3.

Pipeline connection should be stable and reliable, with suitable

temperature resistance, pressure resistance and hydrolysis resistance to

prevent leakage caused by aging or falling off; Materials that come

into contact with water must be resistant to corrosion, oxidation and

high temperatures. Users who must use metal materials are recommended to

use pure titanium.

4. Electrical components should be strictly

selected to ensure safety. Adopt a reasonable connection process to

reduce unnecessary overheating. The quality of the connection wire

between the power supply and the electrolyzer should be ensured. The

connection end must be tightened in a reliable way, otherwise a large

amount of heat will be generated, resulting in potential safety hazards.

III. Conditions of Use and Common Sense:

-

Customers should write accurate and comprehensive product manuals to

ensure that users can use the products correctly and reasonably in

accordance with the instructions;

- Purified/deionized/secondary

distilled water (conductivity <5uS/cm) must be used and C'estbon

purified water is recommended;

- Customers must be reminded to pay

attention to the water level, and it is strictly forbidden to operate

with water shortage to prevent the electrolyzer from burning.

- A PEM

electrolyzer is a device that requires specific conditions to function

properly. Reasonable design, matching, process and use can greatly

extend the service life of the device. High-quality hydrogen products

can be used for 3-5 years.