| Quantity | 3+ units | 10+ units | 30+ units | 50+ units | More |

|---|---|---|---|---|---|

| Price /Unit | $295.27 | $289.25 | $280.21 | $268.16 | Contact US |

CanMV-K230D-Zero V1.0 Development Board (with 32G Memory Card) + 2093 2MP Camera for AI Recognition

$61.23

CanMV-K230D-Zero V1.0 Development Board (with 32G Memory Card) + 2093 2MP Camera for AI Recognition

$61.23

CanMV-K230D-Zero V1.0 Development Board (without Memory Card) + 2093 2MP Camera for AI Development

$55.40

CanMV-K230D-Zero V1.0 Development Board (without Memory Card) + 2093 2MP Camera for AI Development

$55.40

CanMV-K230D-Zero V1.0 Development Board (with 32G Memory Card) for Machine Vision Recognition Camera

$47.63

CanMV-K230D-Zero V1.0 Development Board (with 32G Memory Card) for Machine Vision Recognition Camera

$47.63

3 Axis NCH02 Offline Stand Alone USB CNC NC Card Mach3 Controller for CNC Router Engraving Milling Machine

Package include:

1 x NCH02 Controller Panel

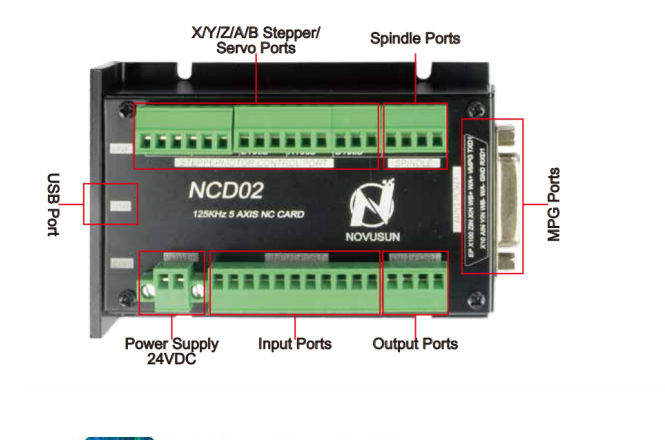

1 x NCD02 Controller Card

1 x USB Flash Disk

1.1 Introduction of Product

Digital Dream has a 20 years history in the numerical control industry, specializing in the research, devel- opment and production of various CNC (Computer Numerical Control) systems.

DigitalDream aims to combine high quality and high reliability with affordability. We produce 1 axis to 6 axes CNC system.

Thank you for choosing digital dream’s motion controllers.With a lots of examples and charts,this manual will describe the features,functions and every operations of our controllers.

Pls read this manual carefully before any assembling and using.Incorrect handling can result in injury and damage to persons and engraving machine.Pls keep the manual carefully for convenient to read it at any time in need.

NCH02 is very professional 3-5 Axis CNC Motion Controller which is based on embedded system.

NCH02 operates as a standalone system with handheld Pendant without the need of a computer,and with a pendant,it makes users very convenient to opreate the machines.

Our controller adopts Embedded Operating System,by which the controller will never get virus-infected.And the controller adopts look-ahead algorithm by which the the controller can read more ahead 30-lines G-code than the operating.

All the features guarantees high preci- sion,accuracy and reliability.And the size is very small,oepreation is very easy,very suitable for all size of Engraving machines,Milling machines and cutting machines and so on.

1.2 Performance parameter of the NCH02

1) Max. 5 Axis,3-5 Axis Optional;

2) 2-4 Axis linear interpolation,any 2 axis circular interpolation;

3) 5 opto isolated digital outputs,8 opto isolated digital inputs;

4) Analog spindle control 0-10V spindle control (can be modified as PWM output);

5) 24VDC power input, minimum 1A;

6) 3.5 inches TFT screen, resolution ratio: 480x272;19 user key;

7) Differential Pulse and direction output signal,Max. 125Khz per axis;

8) USB flash disk support for G code file input;

9) The control system can preview the process path before machining,and it makes the system more steady,working smoothy and precise;

10) Support the Standard MPG or the NVMPG which Digital dream made;

11) Acceleration/Deceleration Mode: S curve;

12) Support un-limited size file for machining;

13) Manual/Automatic machining function;

14) Support the operation to Start a G code from a specific line;

15) Support for “Power Cut” recovery. Data is automatically saved;

16) Support time-lock function;

17) Automatocally Probe function;

18) Supporting Homing,Go to Zero, workpiece origin position saving.

Used in the following areas:

For processing various patterns of colorful molds such as: embossed board, shoe mold, button mold, zipper mold, pattern text stamping and bronzing mold, instrument mold, glass mold.

For the advertising industry such as: Secretary licensing, signs, building models, badges, badges, nameplates, panels, monogram, house numbers, signs, craft decoration, furniture decoration.

For portraits, landscapes, calligraphy and lettering, seals and other art plane engraving, Yinwen, Yang Wen outline, relief production.

With CNC controller, suitable for all kinds of small and medium automation equipment, instruments.

1.3 Appearance, Structure and Size of Product

The NCH02 motion controller contains the handheld motion controller,wiring board,and HDMI digital high-definition transmission cable.

The handheld motion controller and wiring board are communicated by 2 Meter 37 pins HDMI digital high-definition transmission cable which is shielding twisted-pair cable to avoid interference.

Handheld Controller Keyboard Definition

.jpg)

.jpg)

.jpg)

.jpg)

1.4 Explanation of Abbreviations

When operating the NCH02 Controller, the users will come across some English abbreviations. Here a list with explanations:

FRO: Feed Rate Override SRO: Spindle Rate Override

SRJ: Jog Speed Setting

F: Feed rate, unit is mm/min

S: Spindle Speed, unit rev/min.

X: The coordinate code of the X axis.

Y: The coordinate code of the Yaxis.

Z: The coordinate code of the Z axis.

A: The coordinate code of the A axis

BUSY: The system is busy. You still can adjust FRO and SRO

READY: READY mode, any operation can be done

RESET: Reset mode, controller is in “OFF” mode, no operation can be performed

CONT: Continuous mode, each axis can be manually jogged with the arrow keys Step :Manual Step Mode,each axis can be jogged in defined steps

MPG: MPG mode. Operate the machine with the MPG (Manual Pulse Generator) AUTO: Run G code. Auto is showing when file is processing。