| Quantity | 3+ units | 10+ units | 30+ units | 50+ units | More |

|---|---|---|---|---|---|

| Price /Unit | $160.63 | $157.35 | $152.44 | $145.88 | Contact US |

SS-BZ-TC Machining Center CNC Control Panel Lathe Control Panel For FANUC and Mitsubishi Systems

$361.94

SS-BZ-TC Machining Center CNC Control Panel Lathe Control Panel For FANUC and Mitsubishi Systems

$361.94

DDCS-EXPERT (DDCSE) 5-Axis CNC Offline Controller Motion Controller Support PWM Output Compatible with Standard G-code

$407.45

DDCS-EXPERT (DDCSE) 5-Axis CNC Offline Controller Motion Controller Support PWM Output Compatible with Standard G-code

$407.45

DDCS-EXPERT (DDCSE) 4-Axis CNC Offline Controller Motion Controller Support PWM Output Compatible with Standard G-code

$388.02

DDCS-EXPERT (DDCSE) 4-Axis CNC Offline Controller Motion Controller Support PWM Output Compatible with Standard G-code

$388.02

600W E11 Brushless Spindle Motor Air Cooling Spindle Set with Motor Driver (AC 220V) and Motor Clamp

Spindle Motor:

- Peak output power: 600W; Voltage: 310V DC; Current: 2.2

- Peak torque about: 0.6NM

- Idling speed: 9000rpm

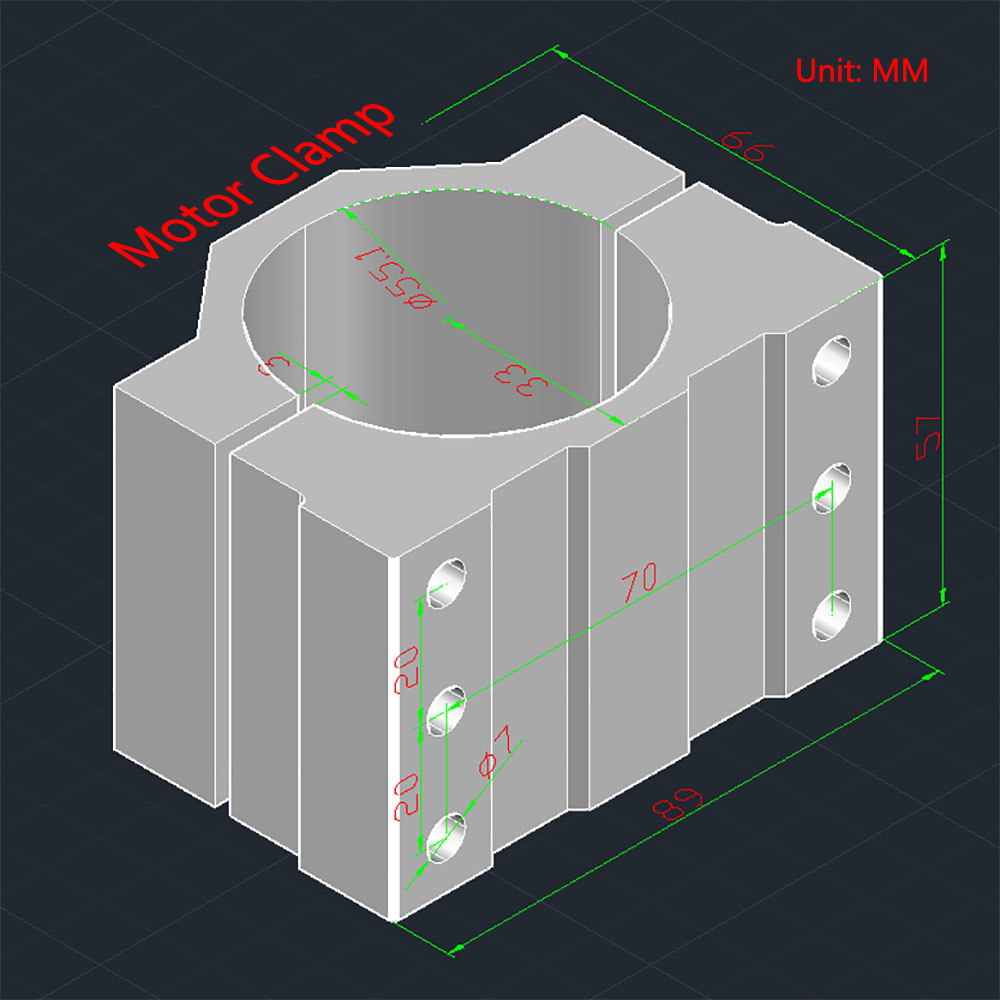

- Spindle diameter: 55MM/2.2"; Standard: ER11 collet holder and 3.175MM collet chuck

- Overall length: 205MM/8.1"; Weight: 1.5KG/3.3LB

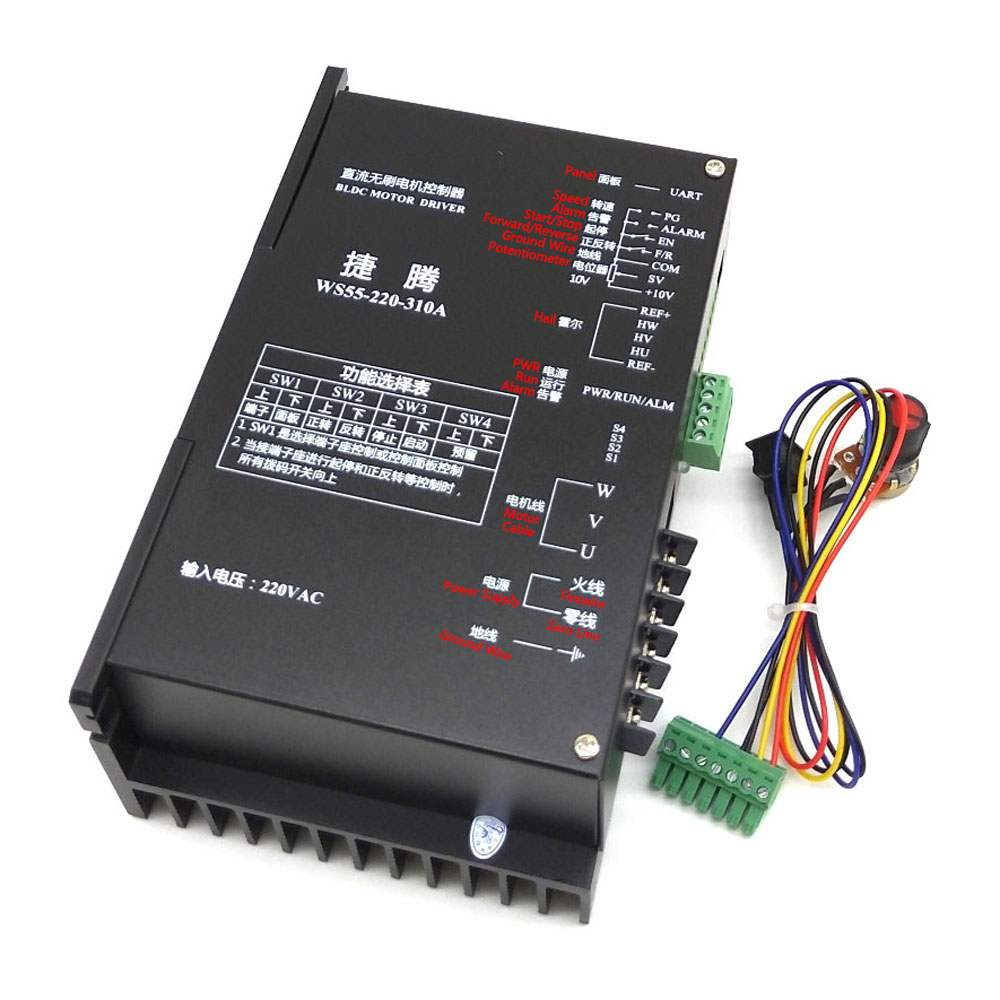

Motor Driver:

1. Description:

The WS55-220-310A motor driver is compatible with Hall and Hall-free modes. It has potentiometer speed regulation function, external 5V voltage speed regulation function, switch machine function, speed output function, alarm output function, forward and reverse function, etc. It also has a protective shell. You can also choose to connect to the dedicated upper computer control panel to display the speed, and can control the controller such as start-stop, forward and reverse rotation, and jog. It is widely used in the control of brushless motors such as mechanical equipment, pumps and fans.

2. Features:

- A variety of speed regulation options are available

- Providing multiple protections

- Compatible with Hall and Hall-free modes

- Can be controlled either through an external dedicated host computer control panel, or through an external potentiometer switch on the terminal block

- High reliability: Brand components and strict testing and verification help ensures its high quality

- Long service life: Electronic components are carefully selected. The controller is tested during the production process to ensure product quality

- Easy installation: can be quickly fixed, connected and removed through the screw holes on the housing

- Multiple protections: under-voltage protection, over-voltage protection, locked rotor phase loss protection and Hall short-circuit phase loss protection

3. Parameters:

- Name: AC 220V input DC brushless motor controller

- Input voltage: 220VAC

- Dimensions: 178.5 x 119.5 x 68.3mm/7 x 4.7 x 2.7" (LxWxH)

Product Parameter Indicators:

- Rated voltage: 220VAC

- Supported speed: When there are 2 pairs of poles, the speed is up to 12000RPM without Hall control, and the speed is up to 22000RPM with Hall control; the speed depends on the motor and load

- Host computer panel control and terminal block control selection: When the host computer control is required, turn the DIP switch S1 down, and the terminal block control is invalid; when the terminal base control is required, turn the DIP switch S2 upward, only the terminal base control can be performed, at this time, the panel of the host computer can display the speed normally. (Note: The following description involves the choice between panel control and terminal block control, so there is no further explanation)

- Four Speed Regulation Modes: 1. External potentiometer: speed regulation through external potentiometer; 2. External special host computer panel: speed regulation through the host computer potentiometer; 3. External voltage: external 5VDC voltage for speed regulation, which must share the ground; 4. PWM speed regulation: external PWM signal, which must share the ground (four kinds of speed regulation cannot be used at the same time)

- Speed Output: PG signal: There is a 5V speed pulse output between this port and the ground (COM). The output frequency is set to P (Hz), the number of motor stages is N, and the speed is F (RPM), then the output speed frequency: P=F*N/60;

- Alarm Output: ALM signal. There is a 5V alarm pulse output between this port and the ground (COM)

- Forward/Reverse (three control modes): 1. Both ends of the switch are connected to F/R and COM respectively, and the forward and reverse rotation is controlled by the switch; 2. DIP switch S2 is toggled up and down for forward and reverse control; 3. External host computer forward and reverse control (Attention: Mode 1 and 2 cannot be used at the same time. When using the switch, the DIP switch S2 is turned up, and when the dial switch is used, the external switch is disconnected;

- Start/stop (three control modes): 1. The two ends of the switch are connected to EN and COM respectively, and the start and stop control is performed through the switch; 2. Toggle the DIP switch S3 up and down to control the start and stop; 3. External host computer for forward and reverse control (Attention: Mode 1 and 2 cannot be used at the same time. When using the switch, turn the DIP switch S3 up, and when using the DIP switch, the external switch is disconnected)

- Compatible with Hall and non-Hall modes: Motors can be used with or without Hall. Requires power off before switching

- Under-voltage and over-voltage protection: The under-voltage protection is enabled and it stops working when the voltage below 90V, the red light flashes 7 times; and it restarts when it is above about 100V. It is recommended that the working voltage of the controller should not be greater than 250V for a long time (attention: it is not recommended to work in high voltage areas)

- Other protections: In case of phase loss, phase line short circuit, Hall phase loss, Hall short circuit, locked rotor and other faults, it will stop working and red light will turn on

- Power light: green light: always on when it is powered on

- Status light: red light: flashes evenly during standby, and turns off after power on. Flashes when faulty

- Insulation resistance: >100MΩ at normal temperature and normal voltage

- Dielectric strength: 0.5KV at normal temperature and pressure, 1 minute

Using Environment and Parameters:

- Storage temperature: -20℃ to +65℃

- Use environment: Occasion: Avoid direct contact with dust, oil fume and corrosive gas; Temperature: 0 to 45℃; Humidity: < 80% (no frost); Vibration: 5.9m/S2 MAX

- Storage humidity: 0~95%RH

* Driver size: 178.5 x 119.5 x 68.3mm/7 x 4.7 x 2.7" (LxWxH)

* Weight: 900G/ LB (with potentiometer and switch)

Package Included:

- 1 x Spindle Motor

- 1 x Motor Driver

- 1 x Cable with Potentiometer and Switch

Functions of Marks Printed on the Motor Controller:

Faults and Treatment Methods:

I. The motor does not rotate

1. Check whether the power supply is normal

2. Check whether the wiring of the motor wire and the Hall wire is correct

3. Whether the wiring of the potentiometer is correct and rotated to the correct position

4. Whether the external speed regulation voltage or PWM signal is connected correctly

II. The speed of the motor is very slow or fast, or it is shaking.

1. Check if the voltage is normal

2. Check whether the phase of the Hall is correct, because it is easy for users to connect the wrong phase of the Hall

III. Alarm keeps flashing

1. Check whether the power supply voltage is normal, because the voltage is too low will cause under-voltage protection

2. Check whether the motor load is too high to cause over-current protection

3. Check whether there is a short circuit or open circuit in the phase line

4. Check whether the Hall wire is short-circuited

Attention:

- After the motor is connected, please run the motor at low speed first, then gradually increase the speed, and then connect a load if there is no problem.

- During use, please pay attention to whether the motor heats up quickly (tens of seconds to one or two minutes). When the temperature rises to the point where people feel very hot, stop the machine in time and find the cause.