| Quantity | 3+ units | 10+ units | 30+ units | 50+ units | More |

|---|---|---|---|---|---|

| Price /Unit | $172.20 | $168.68 | $163.41 | $156.38 | Contact US |

AVC118 Plasma Arc Voltage Height Controller Arc Voltage Height Control for Stepper/Servo Motors

$337.00

AVC118 Plasma Arc Voltage Height Controller Arc Voltage Height Control for Stepper/Servo Motors

$337.00

AVC118 Plasma Arc Voltage Height Controller Arc Voltage Height Control Used to Control DC 24V Motor

$298.14

AVC118 Plasma Arc Voltage Height Controller Arc Voltage Height Control Used to Control DC 24V Motor

$298.14

Wecon IN1101 10.1" 1024x600 Human Machine Interface HMI Display Touch Screen with Ethernet Interface

$117.65

Wecon IN1101 10.1" 1024x600 Human Machine Interface HMI Display Touch Screen with Ethernet Interface

$117.65

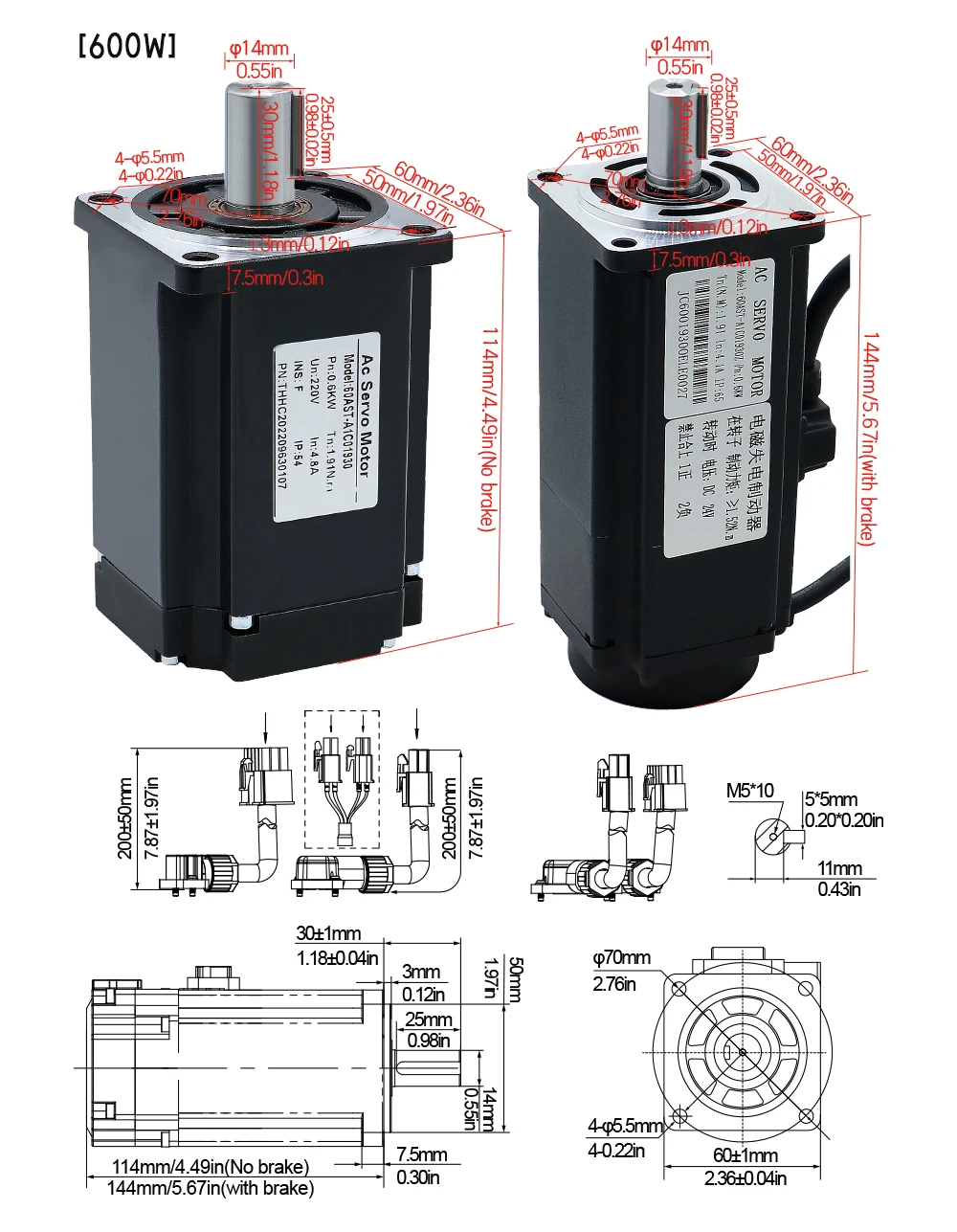

60AST-A1C01930 (without Brake) 600W 1.9NM AC Servo Motor Kit with AC Servo Drive for CNC Engravers

Features:

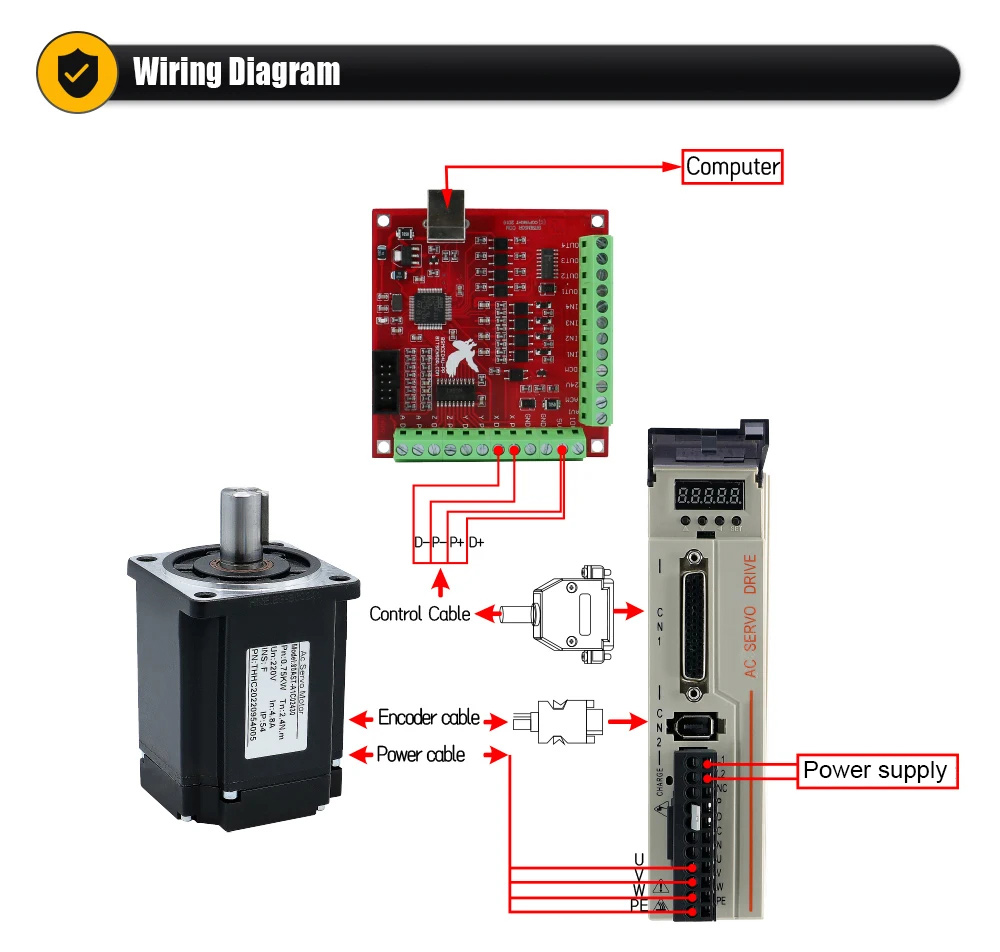

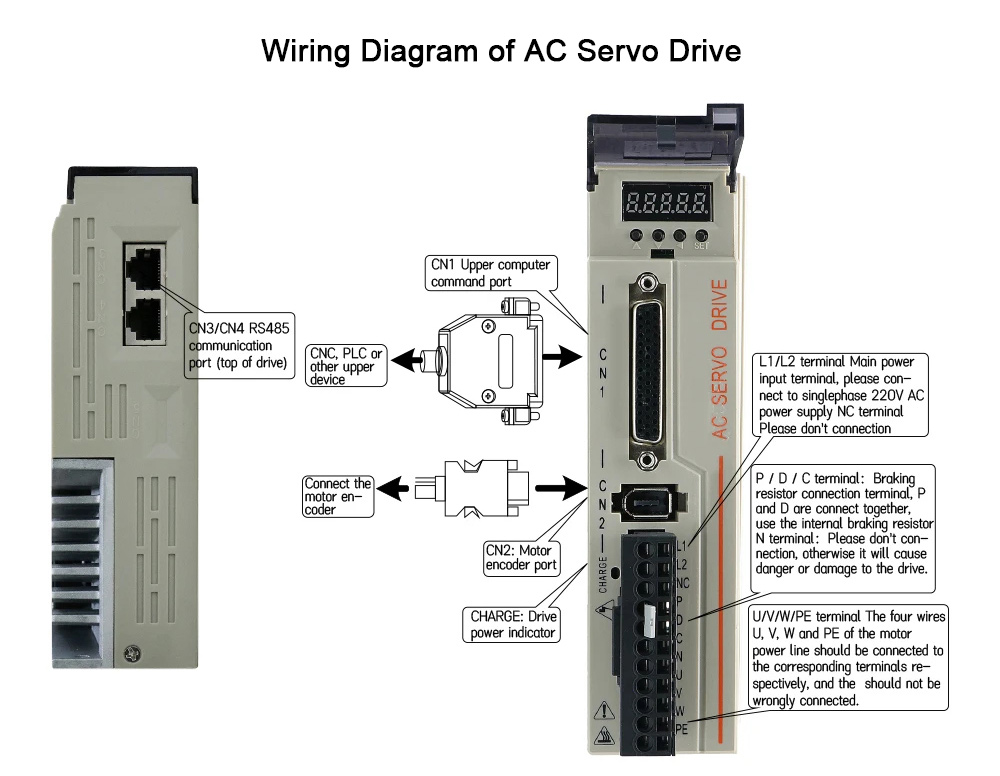

* Supports pulse (5V or 24V pulse signal), analog quantity (0-10V), and Modbus RS485 control

* Supports CNC and PLC systems

* To connect to a 24V pulse signal, two 2K 1/4W resistors need to be connected in series for P+ and D+, otherwise the driver will be burned out

* The motor with brake (optional) needs to be connected to a 24V external power supply and relay

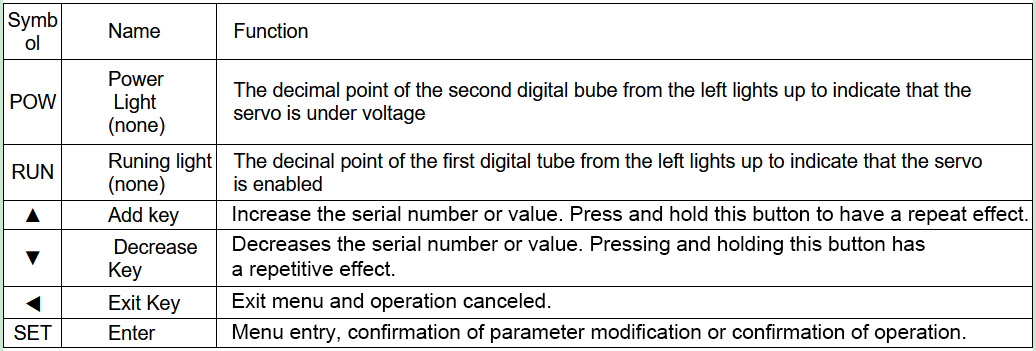

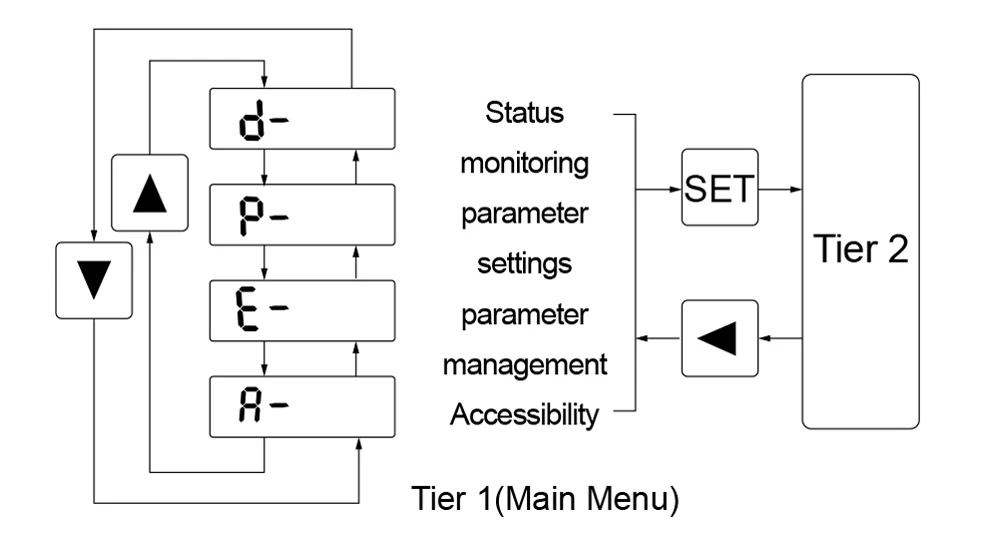

* Power on settings

* Change P-036 to 1 (opposite direction), 0 (positive direction) motor direction conversion parameter

* Change P-098 to 1 (internal enable), 0 (external enable)

* The larger the parameter of P-029 electronic gear ratio, the faster the speed

* Long press the confirm button on E-SEF to display DONE saved successfully. After setting all parameters, power off and restart

Package Included:

* 1 x Servo motor (17bit absolute)

* 1 x AC servo drive

* 1 x Control signal cable

* 1 x 3-meter encoder cable

* 1 x Power cable

* 1 x RS485 cable

* 2 x 2K 1/4W resistors

Packaging Details:

* Weight: 3.5kg

Set After Powering on:

* Find P-098 and change it to 1

*

Find the E-SEF, press and hold the confirmation key until it shows

DONE. Then the parameters will be saved successfully. After all

parameters are set, power off and restart.

Common Parameters:

*

P-036 is changed to 1 (reverse direction), 0 (positive direction) motor

direction conversion parameter. The default is 1 reverse direction.

* P-029 (electronic gear ratio numerator) is 1 by default. The higher the value, the faster the speed.

*

The above parameters are general setting parameters. If you need to

modify other parameters, please contact the technical/sales personnel.

The following parameters are rigid adjustment parameters. No adjustment is needed if the equipment is OK

* P-005 (speed ring rigidity)

* P-009 (position ring rigidity)

* P-006 (generally, the maximum setting is about 100)

* P-019 (generally, the maximum setting is about 300)

*

The specific adjustment of rigid parameters depends on the transmission

structure and load of the equipment. Contact the after-sales service

personnel for specific questions