| Quantity | 3+ units | 10+ units | 30+ units | 50+ units | More |

|---|---|---|---|---|---|

| Price /Unit | $9,239.14 | $9,050.58 | $8,767.75 | $8,390.64 | Contact US |

SEEKU WS7048T 7" HMI PLC All in One Touch Screen HMI with Built-In PLC (24DI 24DO Transistor Output)

$102.87

SEEKU WS7048T 7" HMI PLC All in One Touch Screen HMI with Built-In PLC (24DI 24DO Transistor Output)

$102.87

SEEKU WS7040T 7" HMI PLC All in One Touch Screen HMI with Built-In PLC (24DI 16DO Transistor Output)

$96.03

SEEKU WS7040T 7" HMI PLC All in One Touch Screen HMI with Built-In PLC (24DI 16DO Transistor Output)

$96.03

SEEKU WS7020T 7" HMI PLC All in One Touch Screen HMI with Built-In PLC (12DI 8DO Transistor Output)

$84.76

SEEKU WS7020T 7" HMI PLC All in One Touch Screen HMI with Built-In PLC (12DI 8DO Transistor Output)

$84.76

BORUNTE BRTIRUS1820A 6 DOF Articulated Robot Arm Mechanical Arm 72.8" Arm Span 20KG Load Capacity

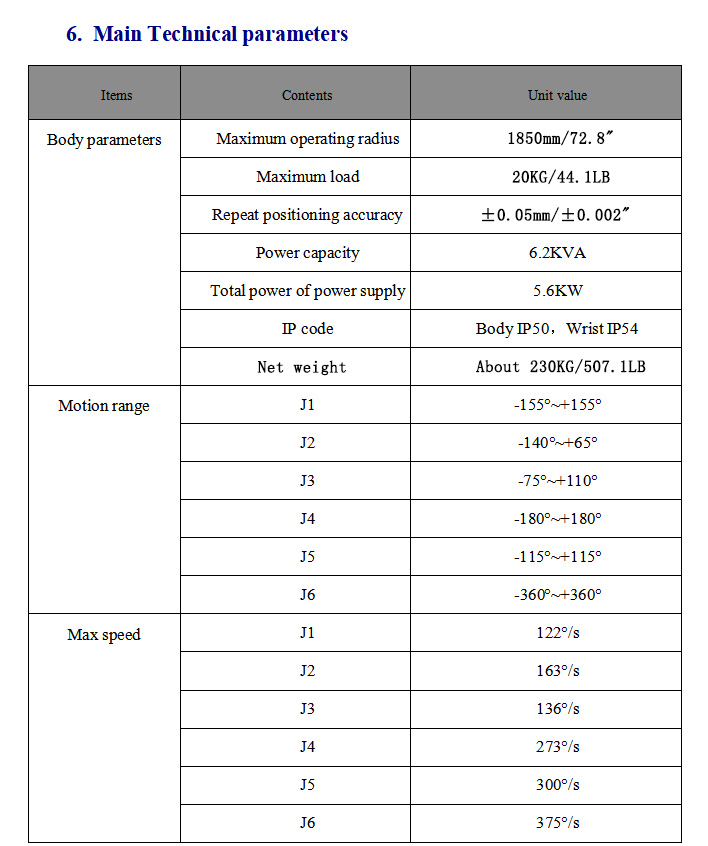

1. Introduction of BRTIRUS1820A:

BRTIRUS1820A six-axis robot is a general-purpose robot. Its shape and structure are compact, and each joint is equipped with a high-precision reducer. The high-speed joint speed can carry out flexible operations in a narrow space, such as handling, stacking, assembly, and other operations. It has a flexible installation method.

2. Application Environment:

(1) Material handling and stacking

(2) Packaging and assembly

(3) Grinding and polishing

(4) Laser welding

(5) Spot welding

(6) Bending

(7) Cutting / deburring

A. Easy to operate and maintain

(1) It can be programmed offline, which greatly shortens the time of on-site debugging.

(2) The plug-in structure and modular design can realize rapid installation and replacement of components and greatly shorten the maintenance time.

(3) The maintenance accessibility of all parts is good, convenient for maintenance.

3. Functions and Features:

A. General layout of robot

BRTIRUS1820A adopts a six axis joint robot structure, and six servo motors drive the rotation of six joint axes through reducer and synchronous pulley. It has six degrees of freedom, namely rotation (x), lower arm (y), upper arm (z), wrist rotation (U), wrist swing (V) and wrist rotation (W).

BRTIRUS1820A body joint is made of high-strength aluminum to ensure the high strength, high speed, high precision and high stability of the machine.

B. Features:

● The structure of servo motor with RV Reducer and harmonic reducer, which has small volume, large working range, fast speed and high precision, and can be integrated with turntable, slide conveyor chain system and other auxiliary equipment.

● The handheld dialogue operator of the control system is simple and easy to learn, which is very suitable for production.

● The robot body adopts partial internal wiring, which is safe and environmentally friendly.

C. Control/Motion System

The robot motion controller and operating system are BORUNTE control system, with complete functions and simple operation; Standard RS-485 communication interface, USB socket and related software, support extended 8-axis and offline teaching.

4. Reducer:

The reducer used on the robot is RV Reducer and harmonic reducer.

The main features of harmonic reducer drive are:

1. The transmission speed ratio is large. The speed ratio range of single-stage harmonic gear transmission is 70~320.

2. High bearing capacity and strong rigidity.

3. High transmission accuracy. The transmission error is only about 1/4 of that of ordinary cylindrical gear transmission. No backlash engagement, small transmission clearance, suitable for reverse rotation.

4. High transmission efficiency and smooth movement. (up to 69% - 96%).

5. Simple structure, few parts and convenient installation.

6. Small size and light weight.

7. It can transmit movement to the confined space.

The main features of RV Reducer transmission are:

1. Compact mechanical structure, light volume, small and efficient;

2. Good heat exchange performance and fast heat dissipation;

3. Simple installation, flexible and light, superior performance, easy maintenance and overhaul;

4. Large transmission speed ratio, large torque and high overload bearing capacity;

5. Stable operation, low noise and durability;

6. Strong applicability, safety and reliability.

D. Servo motor

The servo motor adopts absolute value motor. Its main features are:

1) Accuracy: realize the closed-loop control of position, speed and torque; The problem of stepping motor out of step is overcome;

2) Speed: good high-speed performance, generally the rated speed can reach 2000~3000 rpm;

3) Adaptability: it has strong overload resistance and can withstand loads three times the rated torque. It is especially suitable for occasions with instantaneous load fluctuations and quick start requirements;

4) Stable: stable operation at low speed, suitable for occasions with high-speed response requirements;

5) Timeliness: the dynamic response time of motor acceleration and deceleration is short, generally within tens of milliseconds;

6) Comfort: fever and noise are significantly reduced.

5. Working Conditions:

1) power source: 380V±10% 50HZ±1%

2) temperature: 0℃-40℃

3) best temperature: 15℃-25℃

4) relative humidity: 20-80%RH (No condensation)

5) Mpa: 0.5-0.7 Mpa

Package Included:

- 1 x Robot Arm