| Quantity | 3+ units | 10+ units | 30+ units | 50+ units | More |

|---|---|---|---|---|---|

| Price /Unit | $134.87 | $132.12 | $127.99 | $122.48 | Contact US |

5DOF Low Cost Robot Arm ROS Open Source Robotic Arm (Slave Arm) with XL430-W250-T Servo Motors

$551.16

5DOF Low Cost Robot Arm ROS Open Source Robotic Arm (Slave Arm) with XL430-W250-T Servo Motors

$551.16

5DOF Low Cost Robot Arm ROS Open Source Robotic Arm (Master Arm) with XL330-077-T Servo Motors

$457.01

5DOF Low Cost Robot Arm ROS Open Source Robotic Arm (Master Arm) with XL330-077-T Servo Motors

$457.01

Low Cost Robot Arm ROS Open Source Robotic Arm (5DOF Master Arm + 5DOF Slave Arm) with Servo Motors

$1,005.56

Low Cost Robot Arm ROS Open Source Robotic Arm (5DOF Master Arm + 5DOF Slave Arm) with Servo Motors

$1,005.56

DM-J4310-2EC V1.1 3NM Brushless Servo Motor Joint Motor (Including Drive) (24V) + USB to CAN Module

Download Motor-related Information:

https://gitee.com/kit-miao/damiao/tree/master/%E5%85%B3%E8%8A%82%E7%94%B5%E6%9C%BA/DM-J4310-2EC

Attention:

During the use of the motor, hot swapping, mechanical switches and other scenarios should be avoided. If the above scenarios cannot be circumvented, connect 220uF (50V) electrolytic capacitors, SMDJ26CA (TVS) and other devices in parallel behind the switch to absorb voltage impulses. If it is possible, you can add an over-voltage protection circuit or a hot-swappable protection circuit. For details, please refer to surge test problem analysis and solution based on LM5067 hot-swappable circuit: click the link for https://www.ti.com.cn/cn/lit/an/zhca812/zhca812.pdf?ts=1696232742832

Motor Features:

- Two encoders: single-turn absolute position of the output shaft. Not afraid of losing the absolute position of the output shaft when the power is off.

- Integrated design of motor and driver: compact structure and high integration.

- Supports visual debugging via an host computer. Firmware upgrade is supported.

- Motor speed, position, torque and motor temperature can be fed back through the CAN bus.

- It has double temperature protection function.

- Supports trapezoidal acceleration and deceleration in position mode.

Characteristic Parameters:

Please use the motor reasonably according to the following parameters.

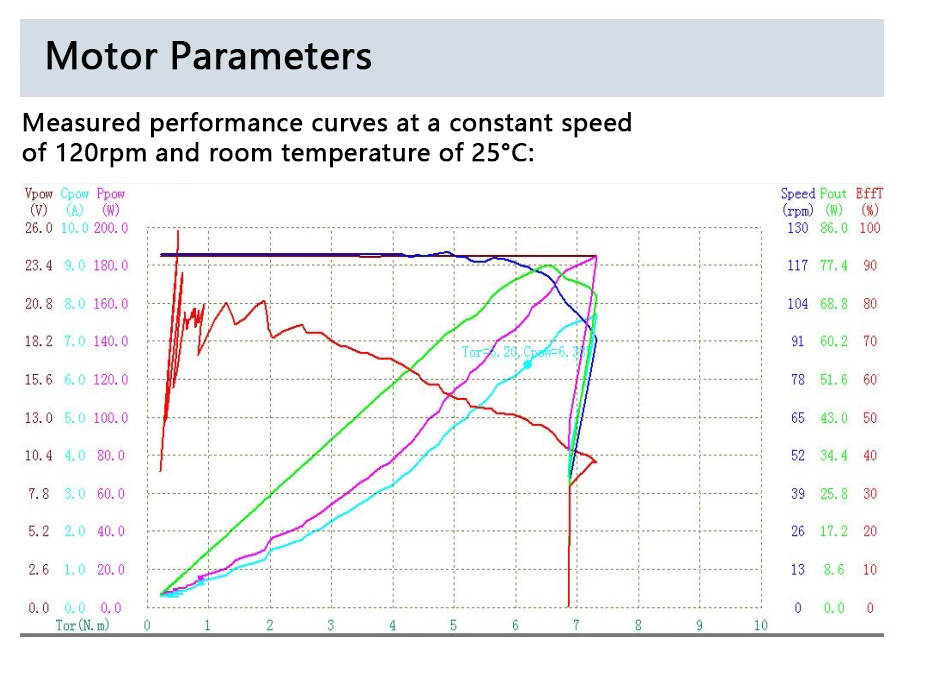

Motor Parameters (24V):

- Rated voltage: 24V

- Rated current: 2.5A

- Peak current: 7.5A

- Rated torque: 3NM

- Peak torque: 7NM

- Rated speed: 120rpm

- Maximum no-load speed: 200rpm

Motor Characteristic Values:

- Reduction ratio: 10:1

- Number of pole pairs: 14

- Phase inductance: 340uH

- Phase resistance: 650mΩ

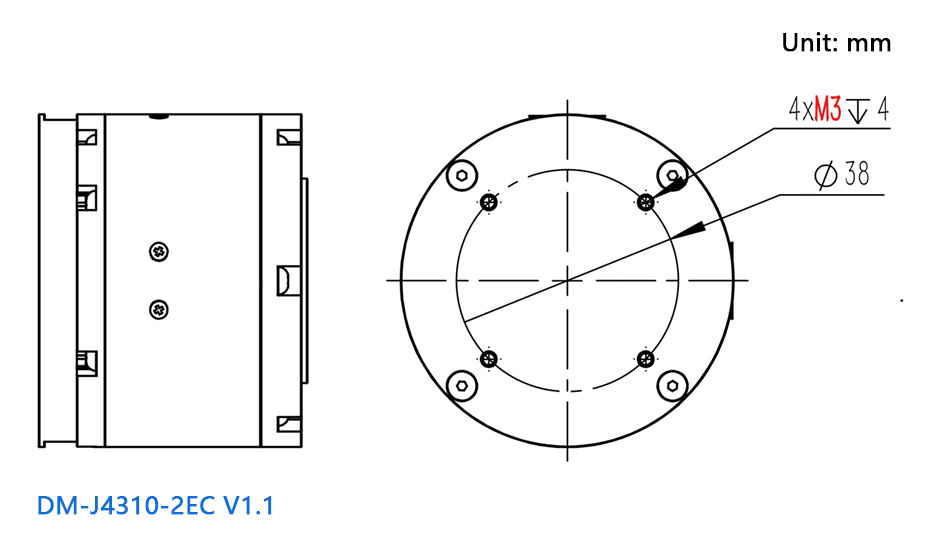

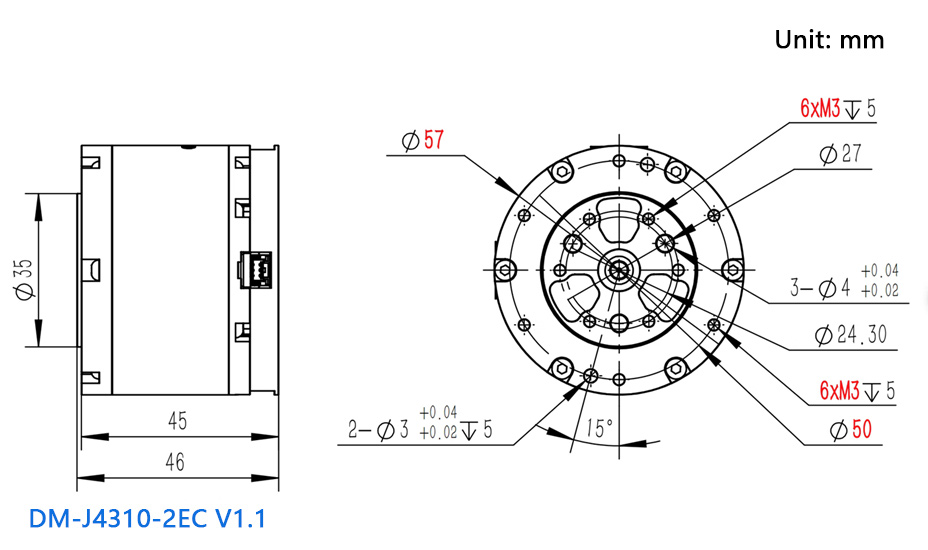

Structure & Weight:

- Outer diameter: 57mm/2.2"

- Height: 46mm/1.8"

- Motor weight: about 300g/0.7lb

Encoder:

- Encoder bits: 14 bits

- Number of encoders: 2

- Encoder type: Magnetic encoder (Single-turn)

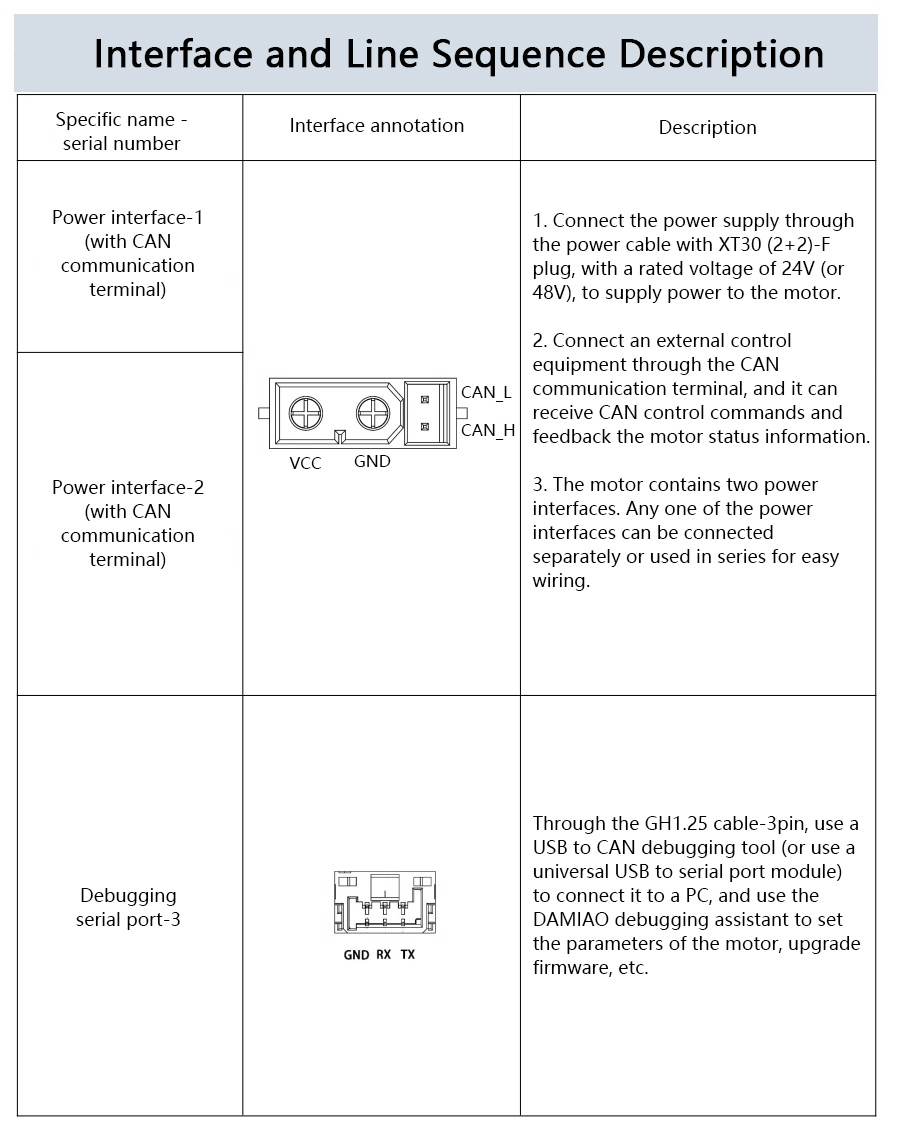

Communication:

- Control interface: CAN at 1Mbps

- Parameter adjustment interface: UART at 921600bps

Control & Protection:

- Control mode: MIT mode, speed mode and position mode

- Protection:

* Drive over-temperature protection: The protection temperature is 120°C. The motor will exit the enable mode when the temperature is over 120°C.

* Motor over-temperature protection: It is recommended not to exceed 100°C according to the use requirements. The motor will exit the enable mode when the temperature is over 100°C.

* Motor over-voltage protection: It is recommended not to exceed 32V according to the use requirements. The motor will exit the enable mode when it is over-voltage.

* Communication loss prevention: The motor will automatically exit the enable mode when no CAN command is received within the set period.

* Motor over-current protection: It is recommended not to exceed 9.8A according to the use requirements. The motor will exit the enable mode when it is over-current.

* Motor under-voltage protection: The motor will exit the enable mode when the power supply voltage is lower than the set value. It is recommended that the power supply voltage should not be less than 15V.

Cautions:

1. Please use the motor in strict accordance with the specified working environment and the maximum allowable temperature range of the winding, otherwise it will cause permanent irreversible damage to the product.

2. Avoid debris from entering the rotor, otherwise it will cause the rotor to run abnormally.

3. Before use, check whether the parts are in good condition. If there are missing parts, aging, damage, etc., please stop using this product.

4. Make sure it's wired correctly. The motor is installed correctly and securely.

5. Do not touch the electronic rotor part when it is in use to avoid accidents. When the torque is high, the motor will heat up, so please be careful not to get burned.

6. Do not disassemble the motor, otherwise it will affect the control accuracy of the motor, and even cause the motor to run abnormally.

Package Included:

- 1 x Motor (including drive)

- 1 x Power cable (including CAN communication terminal): XT30 (2+2)-F plug connection cable

- 1 x Debugging serial signal cable: GH1.25 connection cable-3pin

- 1 x USB to CAN module

Packaging Details:

- Weight: 0.5kg