| Quantity | 3+ units | 10+ units | 30+ units | 50+ units | More |

|---|---|---|---|---|---|

| Price /Unit | $280.91 | $275.17 | $266.58 | $255.11 | Contact US |

High Precision Bench Drill 60x60mm Slide Table Repair Fixture Multifunctional Repair Tools for Watch/Clock Maintenance

$205.99

High Precision Bench Drill 60x60mm Slide Table Repair Fixture Multifunctional Repair Tools for Watch/Clock Maintenance

$205.99

High Precision Bench Drill 40x40mm Slide Table Repair Fixture Multifunctional Repair Tools for Watch/Clock Maintenance

$192.71

High Precision Bench Drill 40x40mm Slide Table Repair Fixture Multifunctional Repair Tools for Watch/Clock Maintenance

$192.71

40*40mm Multifunctional Copper Crossing Slide Table High Precision Repair Fixture for Watch/Clock Maintenance and Repair

$86.15

40*40mm Multifunctional Copper Crossing Slide Table High Precision Repair Fixture for Watch/Clock Maintenance and Repair

$86.15

FUMA FT-618L-NSRI Automation Screw Feeder Rotary Screw Feeding Machine 2000CC Large Capacity with 1-5mm Adjustable Rail

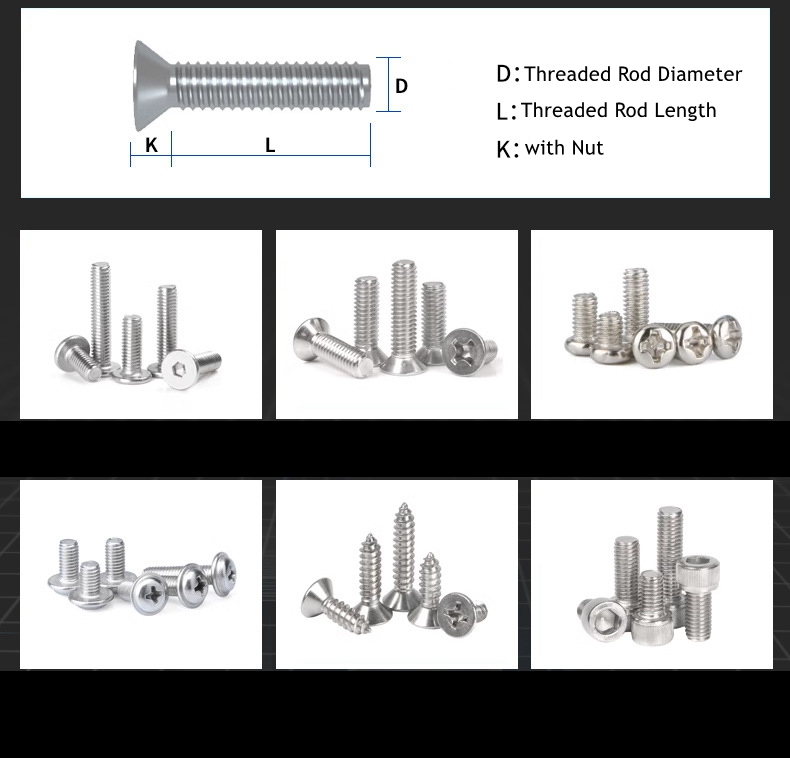

FT-618-NSRI:

- 1.0 to 5.0mm rail adjustable

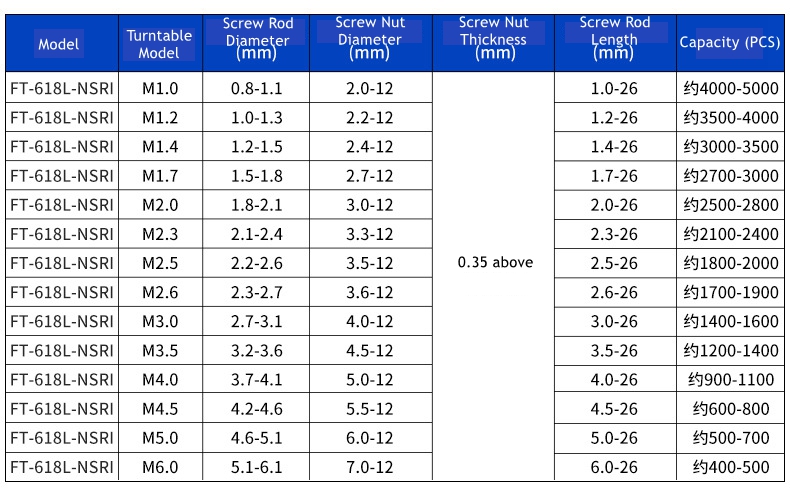

- D: optional turntable screw: M1.0/M1.2/M1.4/M1.7/M2.0/M2.3/M2.5/M2.6/M3.0/M3.5/M4.0/M4.5/M5.0/M6.0

- L: Threaded rod length: ≤17mm

FT-618L-NSRI:

- 1.0 to 6.0mm rail adjustable

- D: optional turntable screw: M1.0/M1.2/M1.4/M1.7/M2.0/M2.3/M2.5/M2.6/M3.0/M3.5/M4.0/M4.5/M5.0/M6.0

- L: Threaded rod length: ≤26mm

Features:

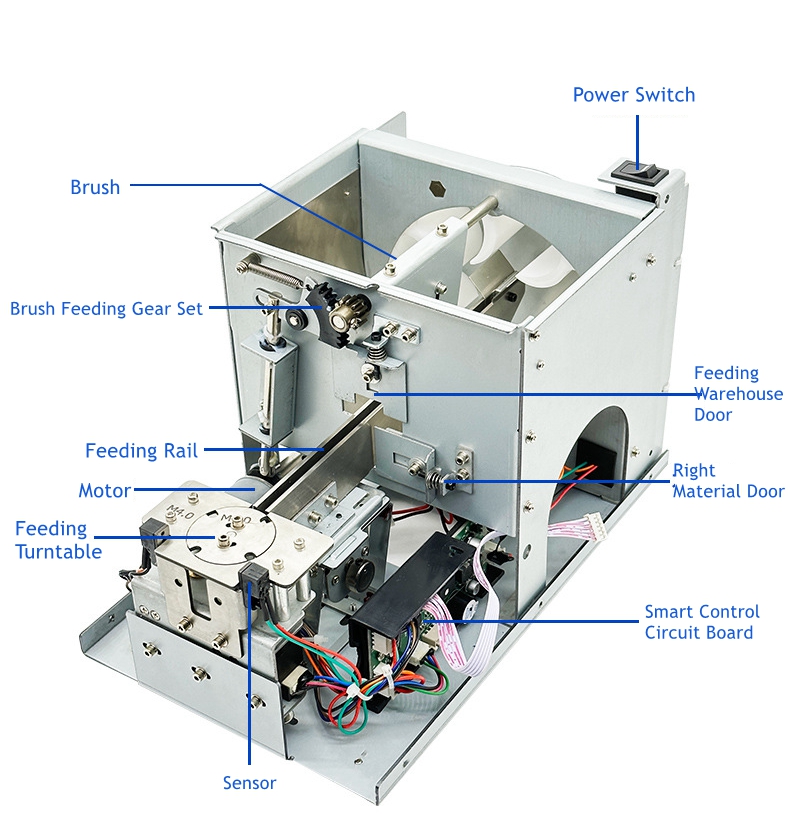

- Equipped with signal output, supports optional turntable M1-M5, does not clamp screws, round head, flat head, countersunk head, with spring plate and gasket, and other screws can be used.

- High definition digital display intelligent screen, precise counting, and CNC adjustment control. The usage quantity is clearly visible, and the feeding speed and turntable speed can be adjusted for higher efficiency.

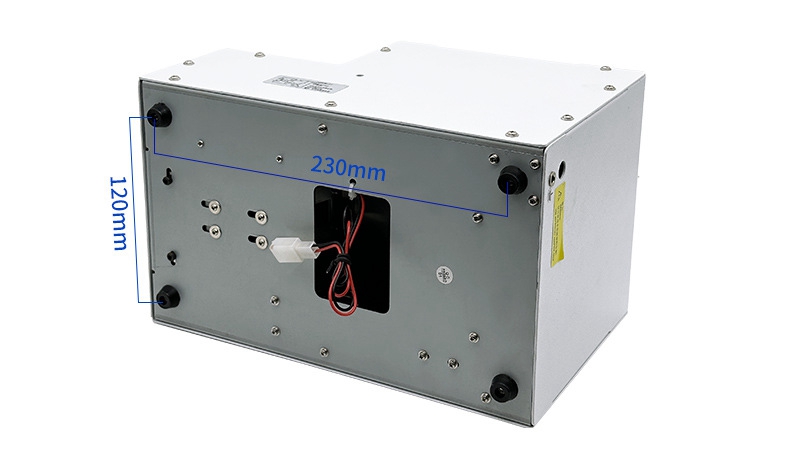

- External signal output: After the screw is in place, the front panel signal light will light up and there will be a signal output. The signal is a power pulse (NPN switch quantity). It is commonly installed by customers as follows: the red line is connected to the PLC receiving terminal, and the black line is connected to the negative terminal, which is used in conjunction with the electric batch mechanical arm.

- Dedicated automatic locking platform, screw automatic locking. Suitable for automation equipment such as XY axis machines, three-axis machines, and four-axis screw locking robots, with a wide range of compatibility.

- Advantages of rotary feeding: single feeding, precise positioning, no jamming, no overlap, no misalignment. Front mounted light sensor, precise sensing, precise material stopping for easy suction by the robotic arm.

- Equipped with a high-speed imported motor and a pure copper core, it has strong power, stable operation, and long service life.

- The integrated feeding wheel is thickened to 3.5mm, ensuring stable feeding and smooth feeding process without easy disassembly.

Panel Button Operation:

1. Press the "SET" button for 3 seconds, the buzzer will sound once to enter the setting mode, and the panel will display the value "A**". At this time, press the up/down button can adjust the value. After the setting is completed, press the "SET" button to enter the parameter adjustment in sequence: "A-**, B-**, C-**, D-**,E-**”

A--**: Adjust the value to 20-100 and adjust the vibration size. The larger the value, the stronger the vibration.

B--**: Adjust the value to 0-60, the vibration delay stop time is 0-9.9S.

C--**: Adjust the value to 0-80, the brush delay stop time after the vibration stops is 0-9.9S.

D--**: Adjust the value to 0-1, where 1 is the counting mode and 0 is the non counting mode.

E--**: Adjust the value to 1-10, with turntable loading waiting speed 1 being the fastest and 10 being the slowest.

- After the last parameter setting is completed, press the "SET" button, the buzzer will sound once, save the data, and return to the working mode.

2. When in working mode, press the down key to reset the current count value.

- Alarm sound explanation: When the turntable rotates 10 times without screws, the buzzer will sound an alarm. When there are screws, the alarm will automatically turn off.

Specification:

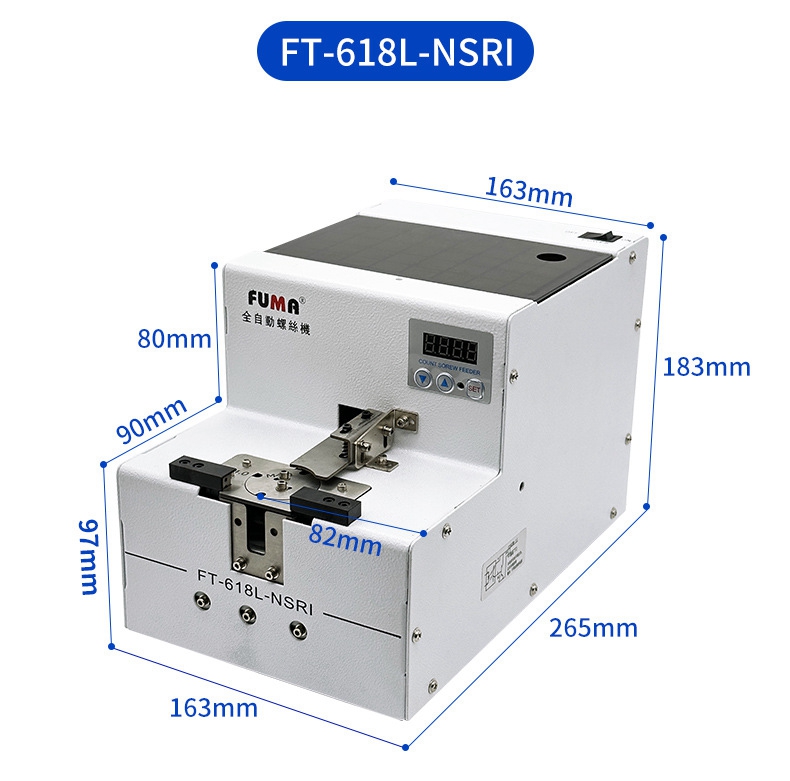

- Model: FT-618L-NSRI

- Input power supply: AC100V - 240V, 50-60Hz

- Output power supply: DC15V 2A

- Product size: 163 x 265 x 183mm

- Net weight: 5.5kg

Package Included:

- 1 x Screw Feeder