| Quantity | 3+ units | 10+ units | 30+ units | 50+ units | More |

|---|---|---|---|---|---|

| Price /Unit | $36.47 | $35.72 | $34.61 | $33.12 | Contact US |

GEEBOON TC22 240W Soldering Station Kit with T245 T210 Handles + C245 C210 Soldering Iron Tips

$93.85

GEEBOON TC22 240W Soldering Station Kit with T245 T210 Handles + C245 C210 Soldering Iron Tips

$93.85

GEEBOON TC22 240W Solder Station Soldering Station + T115 Handle + C115-K Soldering Iron Tip 30W MAX

$81.62

GEEBOON TC22 240W Solder Station Soldering Station + T115 Handle + C115-K Soldering Iron Tip 30W MAX

$81.62

GEEBOON TC22 240W Solder Station Soldering Station Kit with T210 Handle + C210 Soldering Iron Tip

$78.70

GEEBOON TC22 240W Solder Station Soldering Station Kit with T210 Handle + C210 Soldering Iron Tip

$78.70

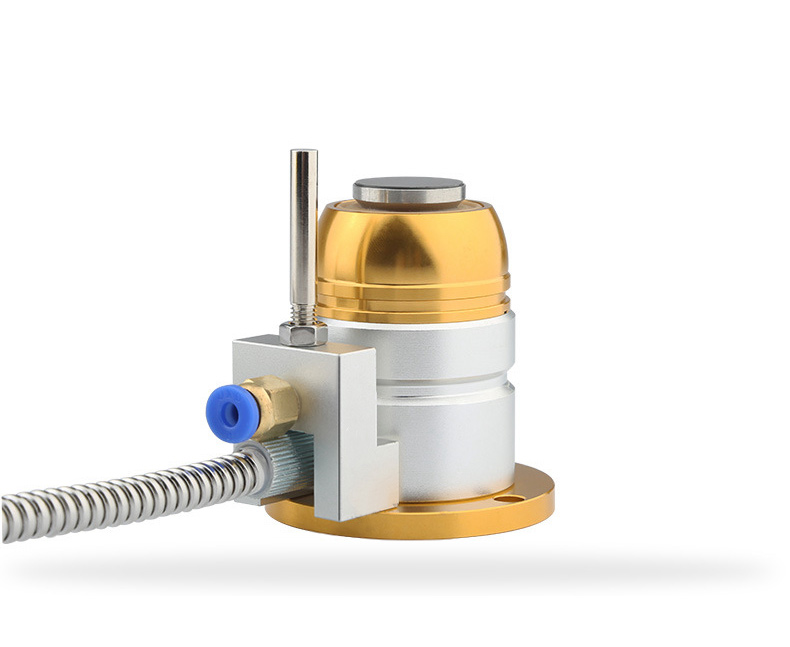

Golden Z Axis Tool Setter Tool Presetter w/ Mouthpiece Yellow Adhesive Tape for Machining Centers

Compatibility:

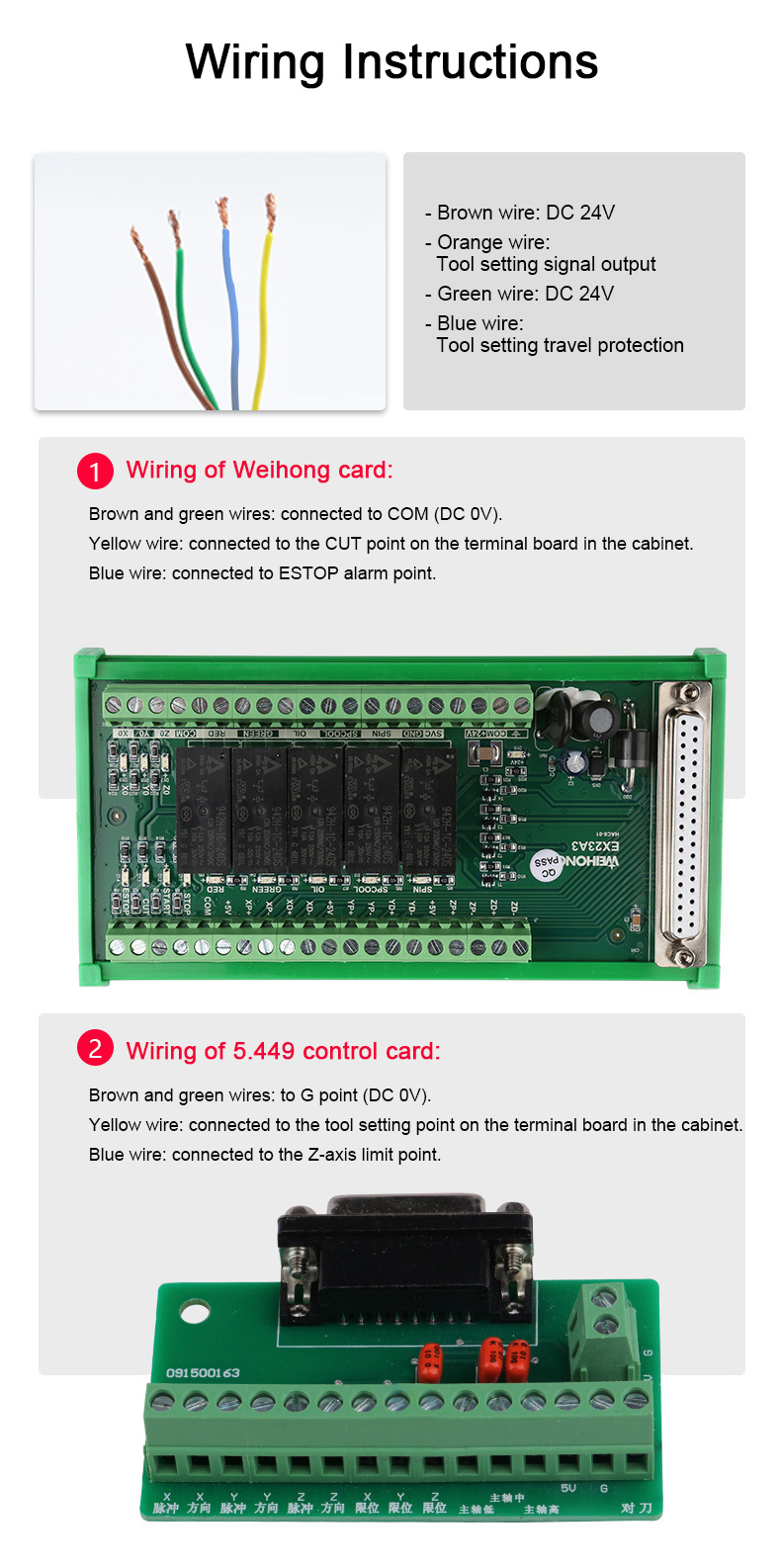

- The tool setter fits controller systems for Weihong, Beijing Jingdiao, Syntec, LNC Technology, Shanlong, FANUC, FAGOR, Mitsubishi and MACH3.

- Before purchasing, please consult the system and equipment manufacturers whether your devices support tool setting and determine the tool setting port.

Features:

- The tool setter can be used for engraving machines, CNC machine tools and machining centers.

- The accuracy of the tool setter reaches 0.001mm/0.00004".

- Selected materials are resistant to corrosion and rust.

- Easy to install and simple and convenient to set up.

- The tool setting instrument adopts environmentally friendly and recyclable raw materials, and the design is light and simple to install. Its bottom magnet can snaps firmly to your device.

- Dustproof and waterproof design: Under the condition of coolant and iron filings flying, it can still work stably.

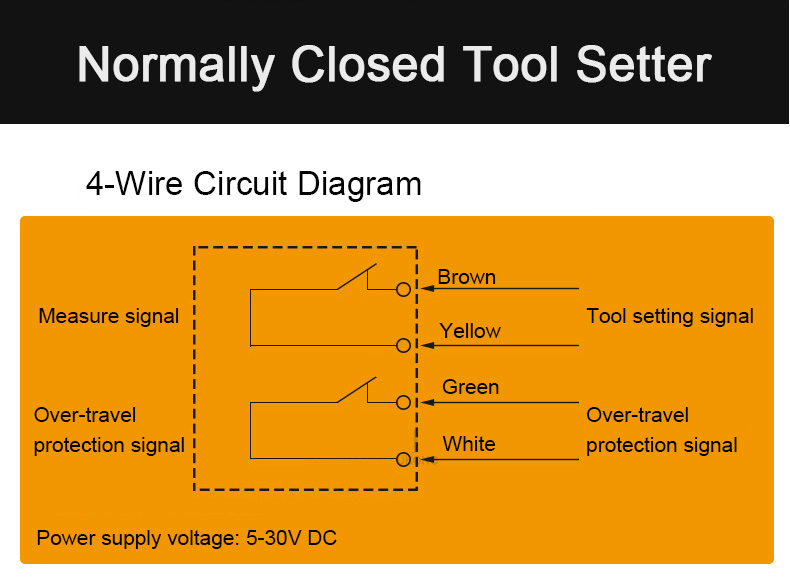

- No built-in amplification required. It does not cause deviations due to fluctuations in temperature and supply voltage at the position of the tool setter, and it can be input directly to the NC program.

- Timely alarm signals: When the travel is exceeded, it will send out an alarm signal in time to avoid other troubles caused by the operation of the equipment, which is more convenient to use.

- High precision and strong anti-interference: The protruding sharp corner of the tool directly touches the tool tip related to the machining size, and its value size is measured and the signal is output, so it is more accurate than using laser and electricity to calculate the average value by converting the amount of light and electricity.

Specifications:

- Repeatability: 0.001mm/0.00004"

- Protection structure: IP67 waterproof

- Contact site material: soft and hard materials

- Protective tube: 1m/3.3ft in length and minimum bending radius R25

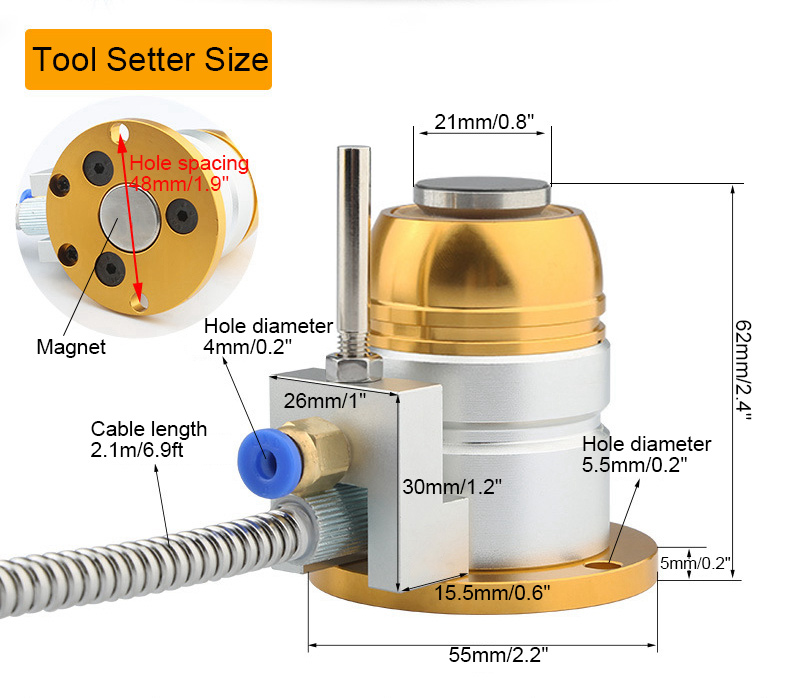

- Travel: 5mm/0.2"

- Electric shock life: 3 million times

- Contact force: 1.5N

- Shell material: ground 4S

- Cable: 2m/6.6ft 4-wire cable is oil-resistant

Package Included:

- 1 x Tool Setter

Attention:

1.The travel of the tool setter cannot be exceeded when contacted, otherwise it is easy to damage the tool setter.

2. Do not let go immediately when touching the contact surface of the tool setter with your hands, so as not to damage the internal structure of the tool setter and affect its use efficiency and life.

3. After tool setting, the tool must be lifted vertically away from the contact surface, and the lateral movement should not damage the tool setter.

Installation Instructions:

1. The contact surface between the tool and the tool setter must be vertical. Vertically down to contact the contact surface, and try to install it in a place with less iron filings on the workbench to avoid affecting the accuracy of the tool setter.

2. Within the rated voltage range, the use voltage is controlled at DC10-30V, the current is below 20mA, and the working temperature is -25°C to 70°C, and its use effect is better.

3. Tool diameter should be controlled below 20mm/0.8", and the tool setting speed should be controlled at 50-200mm/min. The center of the tool should fall in the center of the tool surface.

4. When using the blowing function, the outer diameter of a is 6mm/0.2", the inner diameter is 4-5mm (0.2"), and attention should be paid to cleaning the iron filings attached to the contact surface hygienically.

Application:

- For Jiatie, Beijing Jingdiao, Syntec, LNC Technology, Weihong and MACH3

- CNC engraving machines, engraving and milling machines, jade engraving machines, woodworking cutting machines, etc.