| Quantity | 3+ units | 10+ units | 30+ units | 50+ units | More |

|---|---|---|---|---|---|

| Price /Unit | $175.71 | $172.13 | $166.75 | $159.58 | Contact US |

NRF24+ESP32 Multifunctional Expansion Module WiFi 3-IN-1 Modification Module for Flipper Zero

$47.94

NRF24+ESP32 Multifunctional Expansion Module WiFi 3-IN-1 Modification Module for Flipper Zero

$47.94

1PCS 1:14 RC Model Excavator Tractor Dome Light Engineering Working 360-degree Warning LED Light

$12.63

1PCS 1:14 RC Model Excavator Tractor Dome Light Engineering Working 360-degree Warning LED Light

$12.63

Netherlands Module Hypex NC252MP Power Amplifier Board 2x250W 2-Channel Audio Amplifier Module

$481.46

Netherlands Module Hypex NC252MP Power Amplifier Board 2x250W 2-Channel Audio Amplifier Module

$481.46

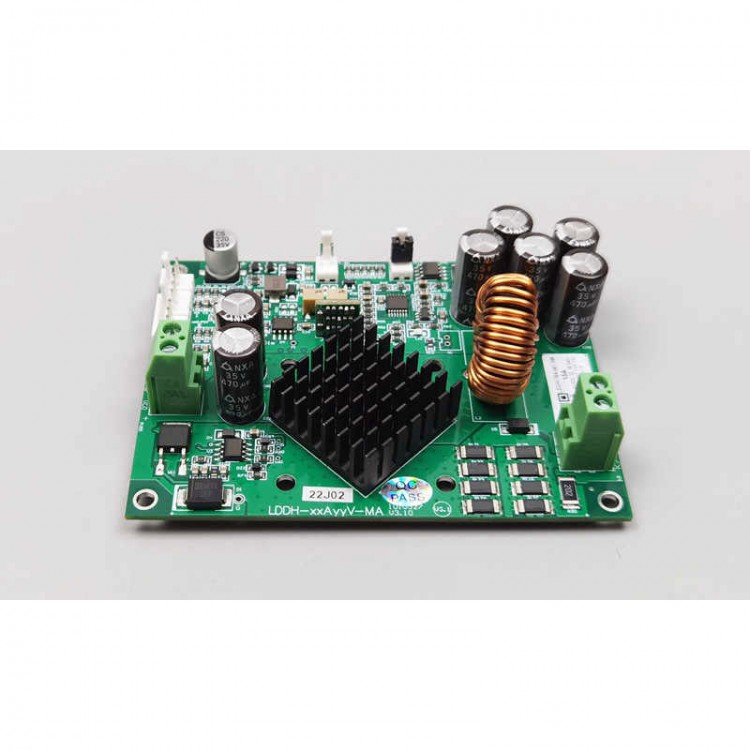

LDDH-10A24V-MA LED Driver Board High Voltage Low Current Laser Diode Power Constant Current Driving Module

Features:

- Suitable for driving high-voltage and low current laser diodes. Suitable for end-pump side-pump lasers, semiconductor, welding, fiber lasers, and other types of lasers. Suitable for welding, marking and other applications.

- Voltage adaptability, can range from a single tube to near the supply voltage.

- Semiconductor laser testing, LED light-emitting diode testing, various diode testing, etc. are all applicable.

- For Hall sensor.

- High speed, adaptive load voltage.

- Ultra high efficiency, no need for additional heat dissipation measures from customers.

- Single board design, small size, high reliability.

- Equipped with internal and external control, that is, two analog inputs, one of which can be connected to a potentiometer.

- High speed analog switches are used for internal and external control switching, which can be directly used for modulation. One analog quantity is the working current, and the other is set as the threshold current.

- Note: 36V/32V/24V refers to the power supply voltage of the board, and the 24V version can also be powered by 12V or 15V (note J1 jumper).

Specification:

- Model: LDDH-10A24V-MA

- Size: 100 x 75 x 35mm

- Current rising/falling speed: 1ms

Examples of applicable products:

- For NLIGHT, OCLARO, BWT...

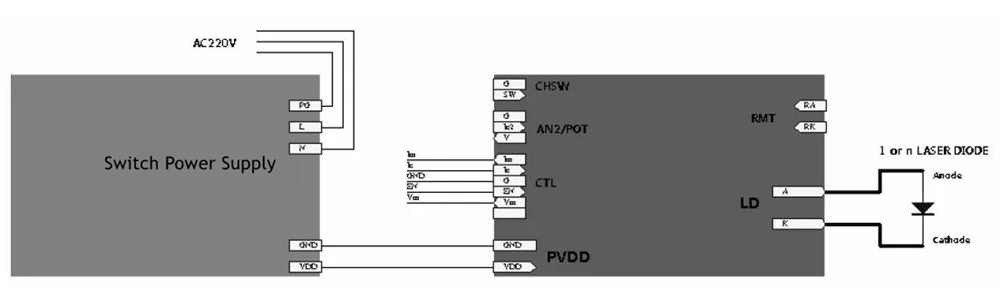

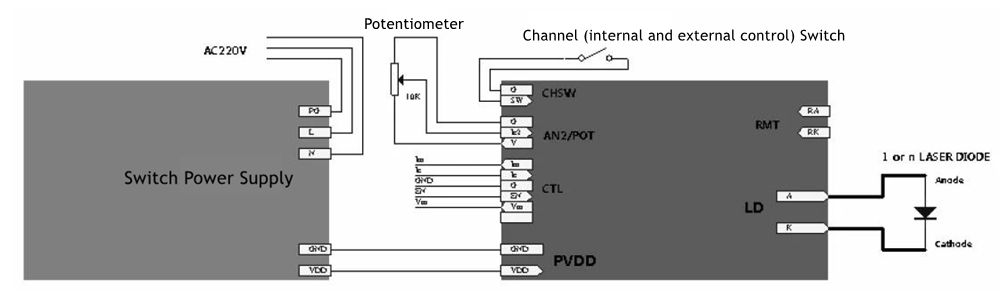

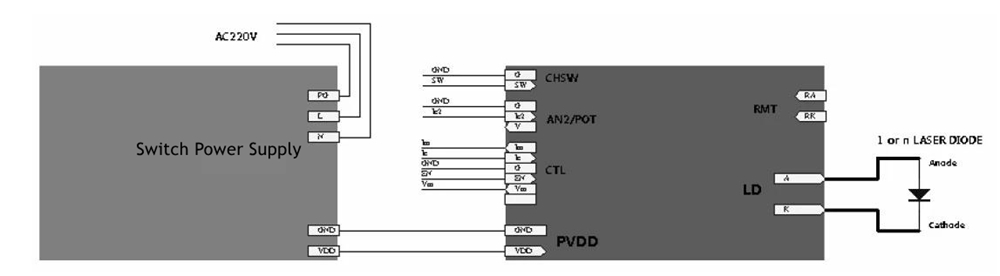

Interface Definition:

- PVDD: power input port/5.0mm wiring terminal

- AN2/POT: second channel analog input terminal, can be connected to potentiometer or analog/2510-3P socket

- CHSW: channel (internal and external control) selection, and if not connected, use the analog input of the CTL interface by default

- CTL: control terminal/2510-6P socket

- LD: output port/5.0mm terminal block

A: Connect the positive pole of the load LD

K: Connect the negative pole of the load LD

Different Application Configurations:

- For applications that only require one analog signal to directly control the output current of the driver board, only the CTL interface can be used to control the driver board, and AN2/POT and CHSW interfaces are not connected to any signals.

- For applications that require internal and external control, such as a power box that has both local signals and external analog signal input ports. Local signals are usually provided by potentiometers or generated by local micro-controllers, while external control signals are provided by the user of the enclosure. At this point, CTL's IC can be used to connect external analog signals, AN2/POT can be directly connected to a 10K (1K-100K is fine) potentiometer, or a local analog signal generated by the IC2 microcontroller, and then CHSW's SW can be used to switch between internal and external control.

- For applications that require fast modulation of current (such as power switches in fiber lasers), CTL's IC input current signal and AN2/POT's IC2 input threshold current signal can be used, and then TTL signal can be directly used to output CHSW's SW to modulate the current. Of course, direct modulation of analog signals, that is, using only ICs with rapidly changing analog inputs, is also possible.

- Note: during modulation, it is generally not adjusted between 0A and the operating current, but rather from the threshold to the operating current. If the current is 0A, it is not good for the laser diode first, because without a maintained threshold current, the thermal shock will be greater, which is unfavorable for the laser diode. Secondly, the debugging performance is also poor, which not only prolongs the time for the current to rise, but also generates extra response time, thereby reducing the modulation speed.

Package Included:

- 1 x LED Driver Board