| Quantity | 3+ units | 10+ units | 30+ units | 50+ units | More |

|---|---|---|---|---|---|

| Price /Unit | $110.61 | $108.36 | $104.97 | $100.45 | Contact US |

M5Stack StamPLC IoT Programmable Logic Controller ESP32S3 Cloud Data Monitoring for Industrial Automation

$66.20

M5Stack StamPLC IoT Programmable Logic Controller ESP32S3 Cloud Data Monitoring for Industrial Automation

$66.20

Coolmay MX3G-70C-48MT 7" HMI PLC All in One HMI with Built-in PLC (24DI 24DO Transistor Output)

$155.14

Coolmay MX3G-70C-48MT 7" HMI PLC All in One HMI with Built-in PLC (24DI 24DO Transistor Output)

$155.14

Coolmay MX3G-43C-22MT 4.3" HMI PLC All in One HMI with Built-in PLC (12DI 10DO Transistor Output)

$95.71

Coolmay MX3G-43C-22MT 4.3" HMI PLC All in One HMI with Built-in PLC (12DI 10DO Transistor Output)

$95.71

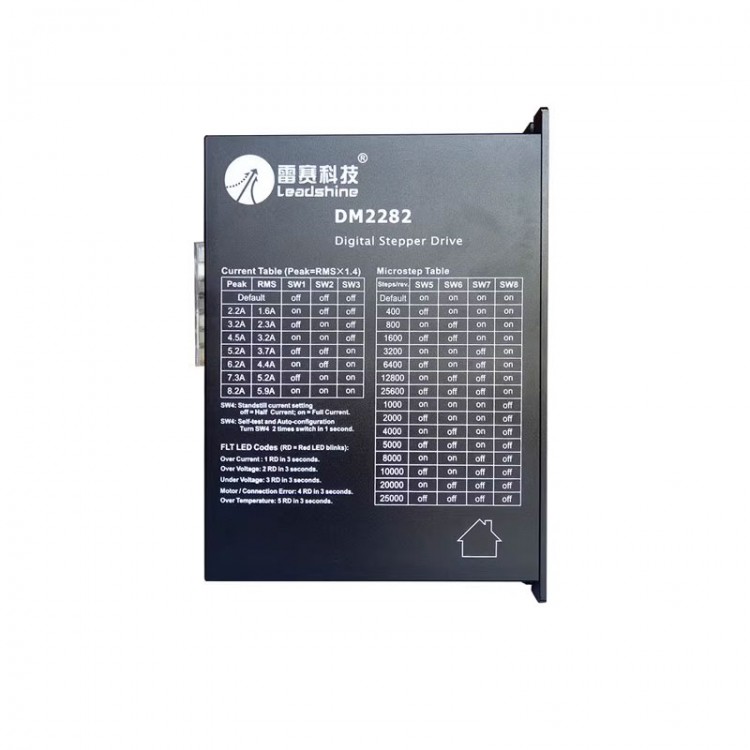

Leadshine DM2282 Two Phase High Voltage Stepper Motor Driver 180-240VAC 200KHz 400-25600PPR Single Driver

Description:

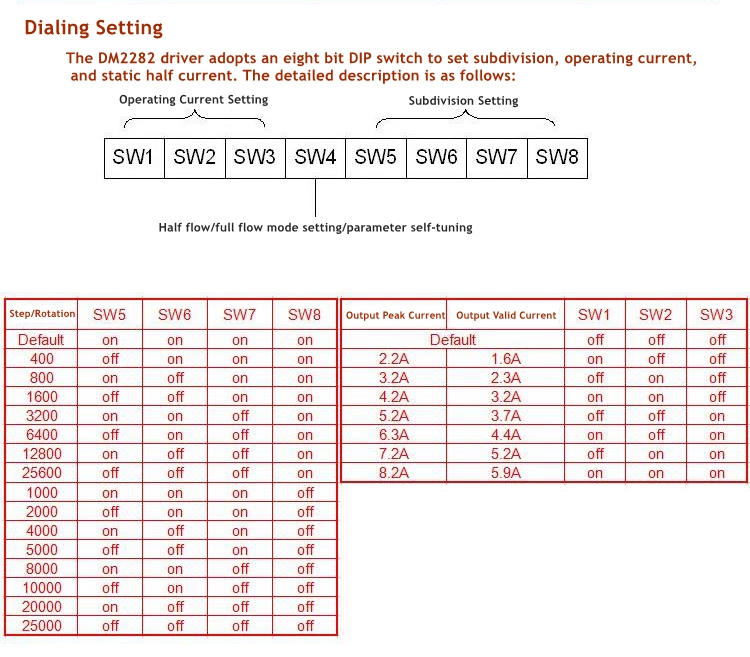

- The DM2282 is a high voltage, fully digital stepper drive developed with advanced DSP control algorithm based on the latest mot ion control technology. It has achieved a unique level of system smoothness, providing optimal torque and nulls mid-range instability. Its motor auto-identification and parameter auto-configuration feature offers quick setup to optimal modes with different motors. Compared with traditional analog drives, DM2282 can drive a stepper motor at much lower noise, lower heating, and smoother movement. Its unique features make DM2282 an ideal choice for high requirement applications.

Features:

- Anti-Resonance, provides optimum torque and nulls mid-range instability

- Motor auto-identification and parameter auto-configuration technology, offers optimum responses with different motors

- Multi-Stepping allows a low resolution step input to produce a higher micro-step output for smooth system performance

- Micro-step resolutions programmable, from full-step to 102,400 steps/rev

- Soft-start during initial power-up

- Supply voltage up to +220 VAC

- Output current programmable, from 0.5A to 8.2A

- Pulse input frequency up to 200KHz

- TTL compatible and optically isolated input

- Automatic idle-current reduction (Reduction rate can be software configured)

- Suitable for 2-phase and 4-phase motors

- Support PUL/DIR and CW/CCW modes

- Over-voltage, Under-voltage, over-current, phase-error protections

Specification:

- Voltage input range: 180 - 240VAC

- Output current: 2.2 - 8.2A

- Maximum current: 8.2A

- Resolution: 0.1A

- Subdivision scope: 400 - 25600PPR

- Controlling signal input current: 7 - 16mA

- Insulation resistance: 500Mohms

- Signal Input: differential/single-ended, pulse/direction or double pulse

- Pulse response frequency: 200KHz

- It can drive 4-wire/8-wire two phase stepper motor

Driver Function:

- PUL+: Pulse input signal; The effective edge of the pulse is adjustable, and the default rising edge of the pulse is effective; In order to reliably respond to pulse signals, the pulse width should be greater than 1.2μs. When using +12V or+24V, a series resistor is required.

- PUL-: In dual pulse mode: CW

- DIR+: Direction input signal: For high/low level signals, to ensure reliable commutation of the motor, the direction signal should be established at least 5μs times ahead of the pulse signal. The initial running direction of the motor is related to the wiring of the motor winding. Swapping any phase winding (such as A+, A- exchange) can change the initial running direction of the motor. When using +12V or +24V, a resistor needs to be connected in series.

- DIR-: In dual pulse mode: CCW

- ENA+: Enable control signal, this input signal is used to enable or disable driver output. When ENA is connected to a low level (or internal optocoupler is conductive), the driver will cut off the current of each phase of the motor, leaving it in a free state and not responding to step pulses. When this function is not needed, the signal enable end should be suspended.

- ENA-: When using +12V or +24V, a series resistor is required.

- FAULT+: The fault signal output is in the form of an open collector.

- FAULT-: The fault output logic can be set through PC software.

- PE: GND

- L/N: AC power input with a range of 180V-240VAC, 220VAC is recommended

- A+/A-: Motor A-phase winding

- B+/B-: Motor B-phase winding

Common Faults:

- Alarm indicator light on:

The motor is connected to the wrong wire. Please check and connect the wire properly.

The voltage is too high or too low, please check the power supply.

- The motor does not rotate and does not maintain torque:

The motor connection is incorrect, please correct the motor connection.

Offline enable RESET signal to be valid, please disable RESET.

- The motor does not rotate and has a holding torque:

There is no pulse signal input, please adjust the pulse width and signal level.

The segmentation is too small, please choose the correct segmentation.

The current setting is too small, please choose the correct subdivision.

The drive is protected, please power off and then power on again.

- Motor rotation direction error:

The phase sequence of the power line is connected incorrectly. Please swap any two phase connections (such as A+, A -).

There is an open circuit in the motor wire, please recheck and connect it correctly.

The direction signal input is incorrect, please change the direction setting.

- Motor torque too low:

The phase current is set too low, please set the phase current correctly.

The acceleration is too fast, please reduce the acceleration value.

Motor stuck, please troubleshoot mechanical issues.

The driver does not match the motor, please replace it with a suitable driver.

- Inaccurate position:

The signal is interfered with, please eliminate the interference.

The segmentation is incorrect, please set the segmentation correctly.

The current is too low, please increase the current.

The motor wire connection is poor, please check and connect it correctly.

- Motor acceleration blockage:

The acceleration time is too short, please increase the deceleration time.

The torque of the motor is too small, please choose a suitable torque motor.

The voltage or current is too low. Please increase the voltage or increase the current.

Package Included:

- 1 x Stepper Motor Driver