| Quantity | 3+ units | 10+ units | 30+ units | 50+ units | More |

|---|---|---|---|---|---|

| Price /Unit | $985.45 | $965.34 | $935.17 | $894.95 | Contact US |

TR500S 24V 300W DC Brushless Motor Tank Chassis Robot All-Terrain Chassis Rubber Track Assembled Load 50KG No Controller

$1,989.77

TR500S 24V 300W DC Brushless Motor Tank Chassis Robot All-Terrain Chassis Rubber Track Assembled Load 50KG No Controller

$1,989.77

ROBSTRIDE04 Collimated Drive Lightweight 120Nm Integrated High Performance Joint Motor Module with Debugger

$273.65

ROBSTRIDE04 Collimated Drive Lightweight 120Nm Integrated High Performance Joint Motor Module with Debugger

$273.65

ROBSTRIDE04 Collimated Drive Lightweight 120Nm Integrated High Performance Joint Motor Module

$262.32

ROBSTRIDE04 Collimated Drive Lightweight 120Nm Integrated High Performance Joint Motor Module

$262.32

Low Cost Robot Arm ROS Open Source Robotic Arm (5DOF Master Arm + 5DOF Slave Arm) with Servo Motors

Advantages:

- Affordable price: Tailored for robotics learning experiments, it offers a high-performance experience at a competitive price, making it easily affordable for every researcher;

- Superior Intelligent Performance: Built-in advanced intelligence system is able to autonomously collect and analyze data to perform the complex tasks you set. This not only simplifies the experimental process, but also provides rich data support for your research;

- Convenient integration experience: Compact design makes it easy to install and integrate. Just a few simple steps to securely fix it on a bench or desktop. Instantly start the experiment journey. Its flexible adaptability allows you to easily cope with a variety of experimental environments and needs.

Product Introduction:

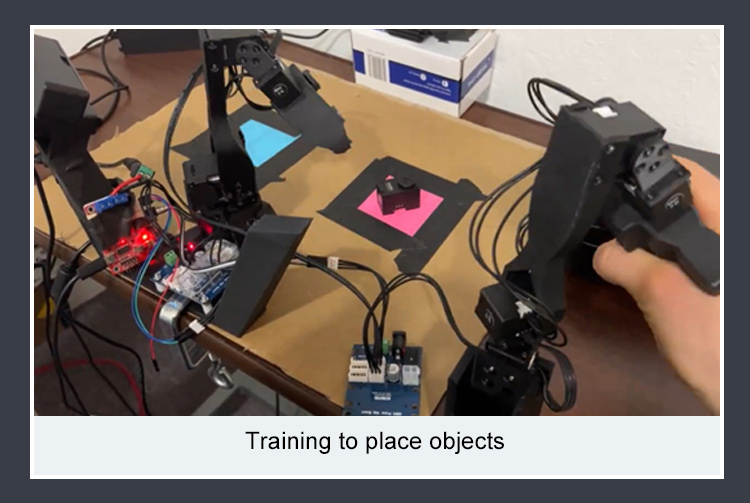

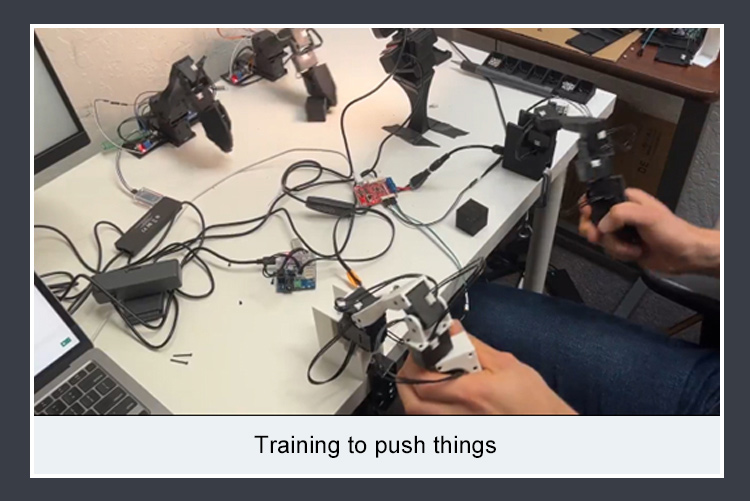

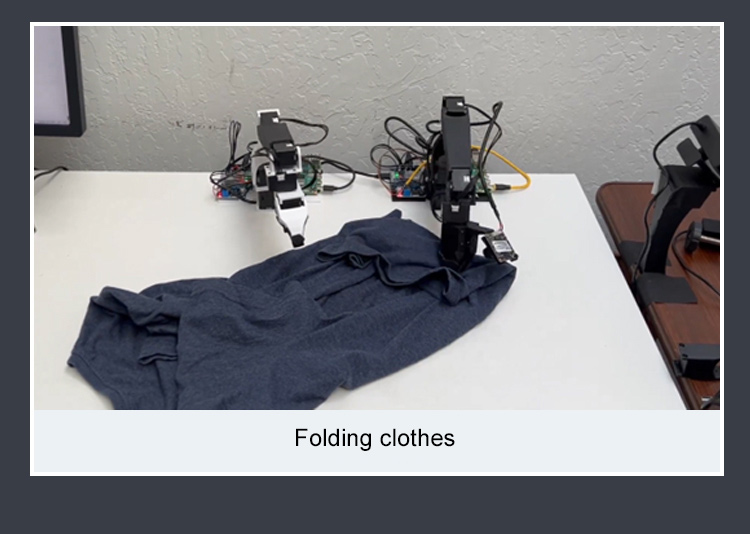

The low cost robot arm has attracted a lot of attention in the field of robotics thanks to its low cost and high performance. The arm integrates general artificial intelligence technology, enabling it to cope with complex and changing task environments, and to demonstrate strong learning and adaptation capabilities.

In terms of hardware configuration, the robotic arm is equipped with high-performance servo motors. With excellent torque and stability, Dynamixel XL430 series motor ensures the reliability and precision of the robot arm when it is performing high-intensity tasks. Dynamixel XL330 series motor improves the overall performance of the robot arm thanks to its lightweight and agile movements. In addition, the lightweight design further enhances the responsiveness and dynamic adaptability of the robotic arm, allowing it to excel in rapid movement and precise positioning.

In a laboratory environment, it is a powerful tool for innovative experiments, demonstrating its superior performance and flexibility. In the field of daily life, as a home assistant to complete simple tasks such as carrying items and positioning objects, the robotic arm can also bring convenience to people's lives.

Packing List (Master Arm + Slave Arm):

Master Arm:

- 6 x Dynamixel XL330-M077-T servo motors

- 1 x FPX330-S101

- 1 x FPX330-H101

- 1 x Multifunction servo driver board

- 1 x Power adapter (5V 5A)

- 1 x Set of 3D printed structural parts

- 1 x Data cable

Slave Arm:

- 2 x Dynamixel XL430-W250-T

- 4 x Dynamixel XL330-M288-T

- 1 x FPX330-H101

- 1 x HN11-1101

- 1 x Multifunction servo driver board

- 1 x Set of 3D printed structural parts

- 1 x Power adapter (12V, 5A)

- 1 x Voltage conversion board (12V-5V)

- 1 x Data cable

Performance Parameters (Master Arm + Slave Arm):

Master Arm:

- Degrees of freedom: 5DOF

- Reach of the robotic arm: About 330mm/13"

- Total span distance: Approx. 660mm/26"

- Accuracy: 1mm/0.04"

- Arm net weight: About 226.84g/0.5lb

- Workload: TBD

Slave Arm:

- Degrees of freedom: 5DOF

- Reach of the robotic arm: About 330mm/13"

- Total span distance: Approx. 660mm/26"

- Accuracy: 1mm/0.04"

- Arm net weight: Approx. 339.3g/0.7lb

- Workload: About 100g/0.2lb

Packaging Details (Master Arm + Slave Arm):

- Weight: 1.5kg

XL330-M077-T Servo Motor:

- Microcontroller: For ARM CORTEX-M0+ (64MHz, 32Bit)

- Position sensor: Non-contact absolute encoder (12Bit, 360°)

- Motor: Cored

- Baud rate: 9,600bps~4Mbps

- Control algorithm: PID control

- Accuracy: 4096pulse/rev

- Transmission ratio: 77.5:1

- Stall torque: 0.215N.m (at 5.0V, 1.47A)

- No-load speed: 383rev/min (at 5.0V)

XL330-M288-T Servo Motor:

- Microcontroller: For ARM CORTEX-M0+ (64MHz, 32Bit)

- Position sensor: Non-contact absolute encoder (12Bit, 360°)

- Motor: Cored

- Baud rate: 9,600bps~4Mbps

- Control algorithm: PID control

- Accuracy: 4096pulse/rev

- Transmission ratio: 288.4:1

- Stall torque: 0.52N.m at 5.0V, 1.47A

- No-load speed: 103rev/min at 5.0V

XL430-W250-T Servo Motor:

- Microcontroller: For ARM CORTEX-M3 (72MHz, 32Bit)

- Position sensor: Non-contact absolute encoder (12Bit, 360°)

- Motor: Cored

- Baud rate: 9,600bps~4Mbps

- Control algorithm: PID control

- Accuracy: 4096pulse/rev

- Transmission ratio: 258.5:1

- Stall torque: 1.4N.m at 11.1V, 1.3A

- No-load speed: 57rev/min at 11.1V

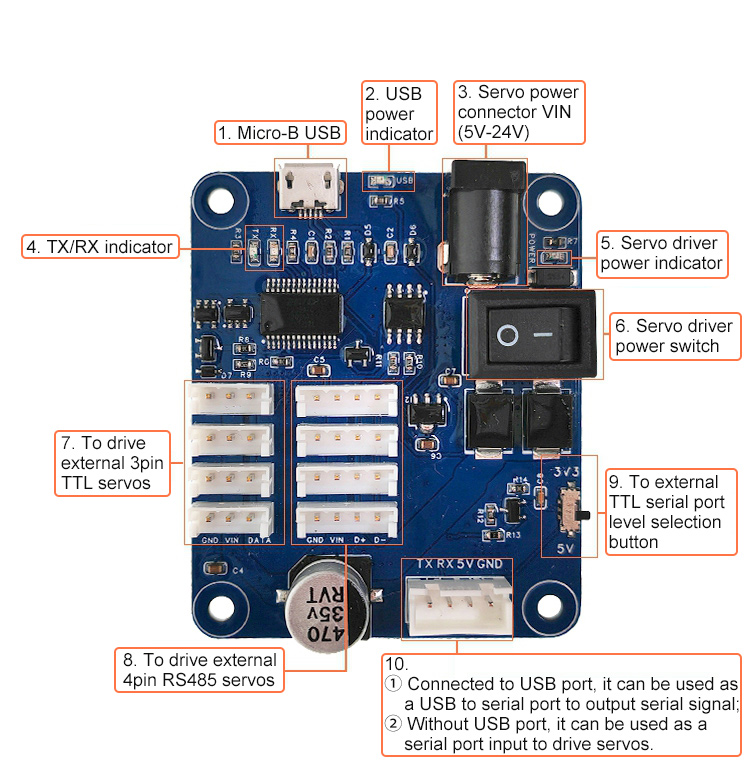

Multifunction Servo Motor Driver Board:

1. Micro-B USB port is used to connect a computer. Users can use the included USB-A to Micro-B communication data cable to connect the servo driver board to the computer.

2. When a computer is connected via the USB port, the USB power indicator on the board will light up, indicating that the connection between the driver board and the computer is normal. If you do not plug in USB, the indicator light will also turn on when the 10th port (as shown in the figure above) is connected to an external 5V power supply.

3. The external power supply of the servo driver board adopts SMPS DC connector (inner diameter 2.5mm/outer diameter 5.5mm and its center is positive), providing 5-24V DC power supply for servos.

4. The TX/RX indicator will light up when the board is communicating with the computer through the USB port, indicating that data is being transferred.

5. The servo driver power indicator indicates that the servo power supply has been connected normally.

6. The servo driver power switch is used to connect and disconnect the external power supply. When the number of servos is too large and the current is large, it is recommended to short-circuit the switch pins and connect them directly.

7. JST B3B-EH-A socket is used to connect servos. Select the corresponding interface based on the communication type of the servos. For AX and MX series servos, it is necessary to connect with servo adapter cables.

8. JST B4B-EH-A socket is used to connect servos. Select the corresponding interface based on the communication type of the servos. For AX and MX series servos, it is necessary to connect with servo adapter cables.

9. A TTL level selector switch serves to select the external serial communication device connected to the 10th port. If logic '1' corresponds to a level of 3V3, turn the level selector switch to 3V3. If logic '1' corresponds to a level of 5V, toggle the level selector switch to 5V. When the USB port is used to drive servos, toggle the level selector switch to the 5V position.

10. The serial input/output interface uses an XH-2.54mm-4P socket. It can be connected to other external serial communication devices.

Note:

- In TTL communication mode, the servo driver board supports up to 3M baud rate. In RS485 communication mode, it supports up to 2M baud rate.