| Quantity | 3+ units | 10+ units | 30+ units | 50+ units | More |

|---|---|---|---|---|---|

| Price /Unit | $198.22 | $194.18 | $188.11 | $180.02 | Contact US |

CM600 6-Axis CNC Motion Controller Board DC24V 24 Inputs and 18 Outputs with Display for CNC 3D Real-time Motion Tracking

$956.76

CM600 6-Axis CNC Motion Controller Board DC24V 24 Inputs and 18 Outputs with Display for CNC 3D Real-time Motion Tracking

$956.76

CM400 4-Axis CNC Motion Controller Board DC24V 16 Inputs and 12 Outputs with Display for CNC 3D Real-time Motion Tracking

$490.36

CM400 4-Axis CNC Motion Controller Board DC24V 16 Inputs and 12 Outputs with Display for CNC 3D Real-time Motion Tracking

$490.36

CM300 3-Axis CNC Motion Controller Board DC24V 12 Inputs and 8 Outputs with Display for CNC 3D Real-time Motion Tracking

$373.77

CM300 3-Axis CNC Motion Controller Board DC24V 12 Inputs and 8 Outputs with Display for CNC 3D Real-time Motion Tracking

$373.77

M3C-2010 Dual-axis Programmable CNC Motion Controller Step Servo Motor Controller Replacement for PLC

Description:

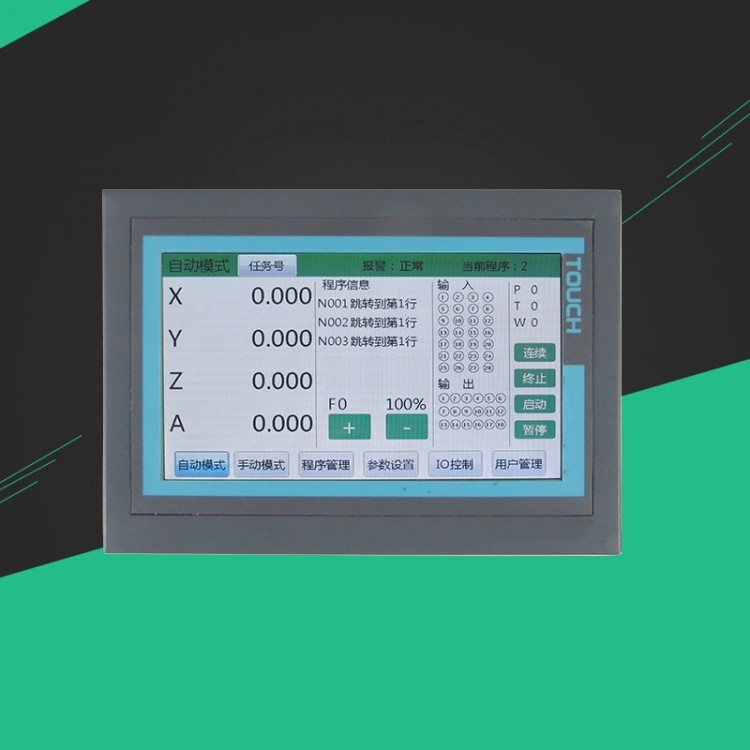

- The M3C series micro CNC system adopts motion logic hybrid control and configuration technology, combined with Chinese guided programming, to achieve comprehensive control of the production process. By using the built-in touch screen of the system to write programs, view and control the production process, the requirements for CNC professional skills can be greatly reduced, resulting in significant cost savings. With the help of the micro CNC system configuration management software, users can quickly achieve custom functions and human-machine interfaces without the need for computer programming. Of course, the control system comes with comprehensive software functions that users can directly use, modify, or even create new interfaces and configure functions.

Features:

- Multi logic and multi task interface configuration function

- 7-inch touch screen time lock function

- Multiple sets of timers and M registers

- Pulse frequency can reach 400KHz

- Equipped with arc/line interpolation function

- Can execute 20 programs with logical relationships simultaneously

- Customizable display interface to achieve product privatization

- Can control 1-4 axes and support 1 electronic handwheel

- 28 inputs/18 outputs

- USB import/export program and startup screen

Functions:

- Customize interface styles and functions.

- Full touch display screen, English operation, user-friendly and intuitive.

- English tabular programming reduces the overall requirement for CNC professional skills.

- External switch, flexible and convenient.

- Support power outage memory function.

- Supports multi-threaded task programming, supporting 20 threaded tasks simultaneously.

- Supports serial and parallel tasks.

- Support cutting, copying, and pasting processing instructions during program editing.

- Supports powering on to return to mechanical zero, manually returning to mechanical zero, and program instructions returning to mechanical zero.

- Support time lock machine.

- Timer instruction, M-register instruction (helps implement complex actions with multiple logic and threads).

- Support external input port control output port status.

- Limit protection, supporting both hard and soft limits.

- Collaborate with servo motors, stepper motors, and I/O ports to achieve automatic and manual operation.

- Any input port external switch, defining functions such as start, pause, alarm, emergency stop, limit, etc.

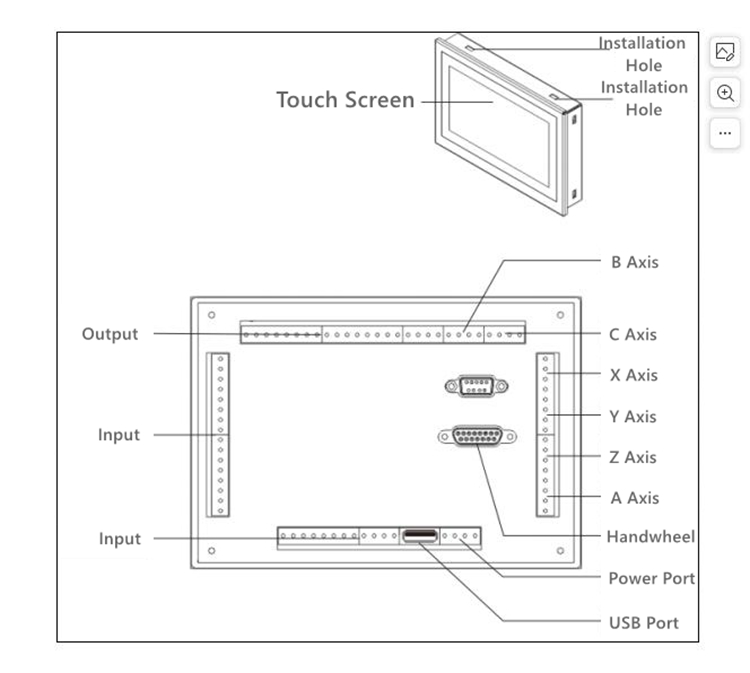

The control system mainly consists of the following parts:

- High precision and high speed CPU

- Specialized motion control chip

- 7-inch color touch screen display (resolution: 800 x 480)

- Input/output (28 channels of photoelectric isolation 24V input, 18 channels of photoelectric isolation 24V output, but channel rated current is 500mA)

- Equipped with a standard MPG interface and external pulse reception

- Shell alloy material, sturdy and durable, with a simple and elegant appearance

Specification:

- Control precision: 0.001

- Maximum data: +/- 99999.999

- Support 46 programming instructions

- Each device can store up to 12 program files, and each program file can perform 20 thread tasks simultaneously, write a maximum of 512 lines of program for a single thread task

- Maximum pulse output frequency: 350K

- The maximum movement speed of the feed axis is 21mm/min

- Number of control axes: 1-4 axes (X, Y, Z, A)

- Linkage axes: X, Y, Z, A-axis linear interpolation, X, Y-axis circular interpolation

- Non-linked axes: X, Y, Z, A axes

- Feed rate multiplier: 10% -500% adjustable, with an increment of 10%

- Electronic gear: numerator: 1-99999; denominator: 1-99999

- Safety protection: overvoltage, overcurrent, anti reverse connection

- Precision compensation: reverse clearance compensation

- Size: L x W x H = 200 x 140 x 42mm

- Embedding port size: L x W x H = 192 x 130 x 37mm

Package Included:

- 1 x Motion Controller

Precaution:

- The working temperature of the control system is 0-40℃. When the ambient temperature exceeds this range, the system may malfunction or even crash.

- The relative humidity should be controlled between 0-85%

- Special protective measures must be taken when working in special environments such as high temperature, high pressure, and corrosive gases.

- Prevent dust, dust, metal and other debris from entering the controller.

- The LCD screen of the controller (fragile items) should be protected to keep it away from sharp objects; Prevent objects in the air from colliding with the LCD screen; When there is dust on the screen that needs to be cleaned, gently wipe it off with a soft tissue or cotton cloth.

- The operator performing the operation for the first time should understand the correct usage method of the corresponding function before proceeding with the corresponding operation. For unfamiliar functions or parameters, it is strictly prohibited to operate or change the system parameters arbitrarily.

- When there is an abnormal situation in the system that requires maintenance of the corresponding connection or socket connection, the system power should be cut off first. Perform necessary maintenance again.

- Technical personnel who have not received training, or units or individuals who have not been authorized by our company, are not allowed to open the control system for maintenance operations. Otherwise, the consequences will be borne by oneself.

The following situations are not covered by the warranty:

- Any human or accidental malfunction that violates the usage requirements, especially incorrect or reversed voltage connections.

- Damage caused by connecting sockets with live plugging systems, natural disasters, and other reasons.

- Damage caused by unauthorized disassembly, modification, repair, etc.