| Quantity | 3+ units | 10+ units | 30+ units | 50+ units | More |

|---|---|---|---|---|---|

| Price /Unit | $124.17 | $121.63 | $117.83 | $112.76 | Contact US |

BG-612506 High Precision Angle Grinder Bracket 45°Adjustable 150MM Telescopic Slide Rail Cutting Machine Tools

$102.83

BG-612506 High Precision Angle Grinder Bracket 45°Adjustable 150MM Telescopic Slide Rail Cutting Machine Tools

$102.83

HOBBY-MIO HM-03 Mini Professional Entry-level Desktop Air Pump 18W with 0.2mm Lightweight HM230 Spraying Pen for Model Coloring

$111.35

HOBBY-MIO HM-03 Mini Professional Entry-level Desktop Air Pump 18W with 0.2mm Lightweight HM230 Spraying Pen for Model Coloring

$111.35

HOBBY-MIO HM-03 Mini Professional Entry-level Desktop Air Pump 18W with 0.3mm Lightweight HM231 Spraying Pen for Model Coloring

$107.47

HOBBY-MIO HM-03 Mini Professional Entry-level Desktop Air Pump 18W with 0.3mm Lightweight HM231 Spraying Pen for Model Coloring

$107.47

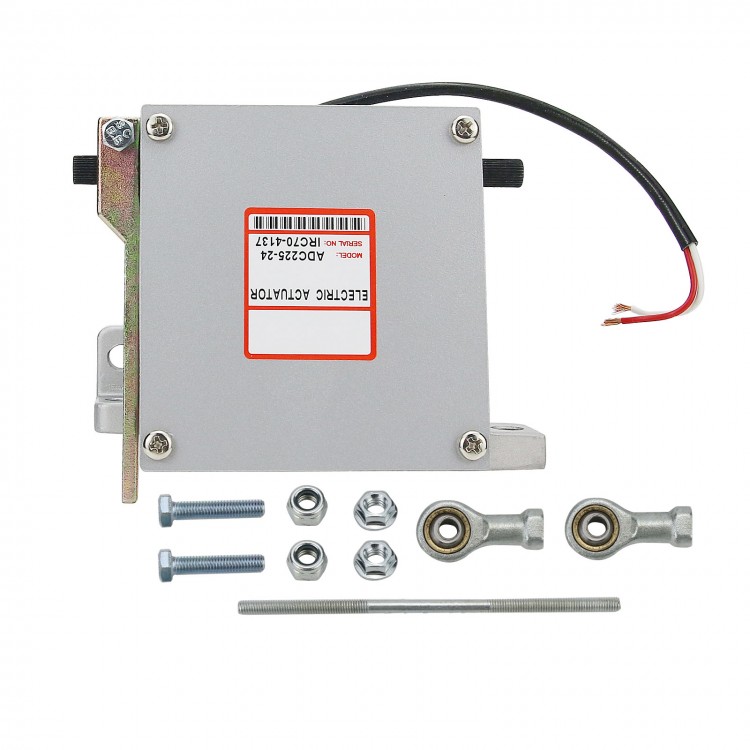

Maxgeek ADC225 Generator Set Actuator ESC Electric Regulating Actuator Speed Controller 12V/24V

Description:

-The 225 Series actuator is a rotary output, linear torque proportional electric servo designed for mechanical actuation of fuel system control levers. The actuator is energized by appropriate speed control unit signals, and is capable of 25 degrees rotation.

-It is suitable for ESD55000E, ESD5111 speed governor to control engine speed, featuring good performance, longevity and stability.

Specification:

Working pressure: 12V DC/24V DC

Working angle: 28 degrees

Working Current: less than 4A

DC resistance:4.5Ω

Maximum torque:4Nm

Hit: 20G

Vibration: less than 500Hz.

Force: 6.2 lb. (27.5N)

Operating stroke: 0.80 in. (21 mm)

Response time (10-90%, 2-19 mm): 35 msec.

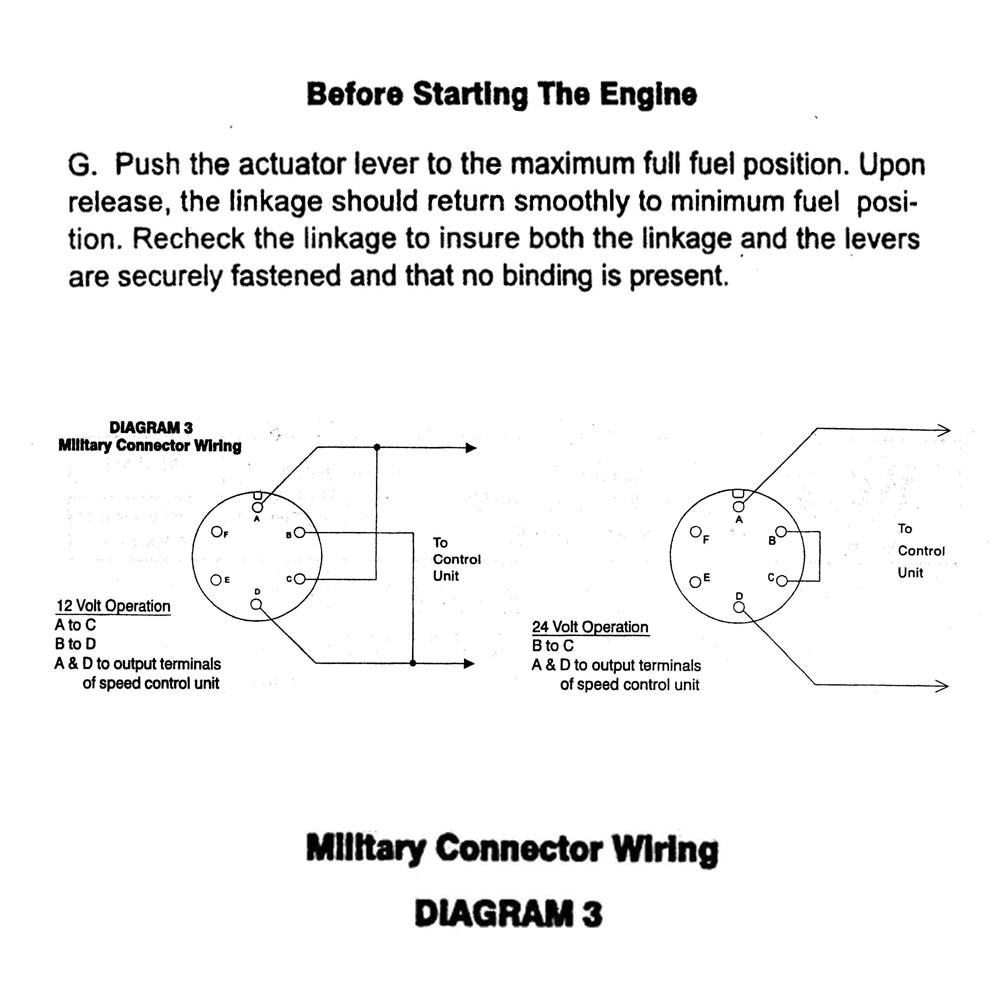

Operating voltage: 12 or 24V DC

Nominal operating current: 4.0A (12V DC version); 2.0A (24V DC version)

Maximum Current: 5.8A (12V DC version); 3.1A (24V DC version)

Operating Temperature: -40 to +95℃

Relative Humidity: up to 100%

Vibration: 20g, 20-500 Hz

Shock: 20g @ 11 msec.

Weight: 2.2kg

Mounting:

Requires camshaft bearing retainer kit

P3000 pump

KT275

P7000 pump

KT276

Mating Connector:

EC1300

Mating Cable Harness:

CH1215

Installation Instructions:

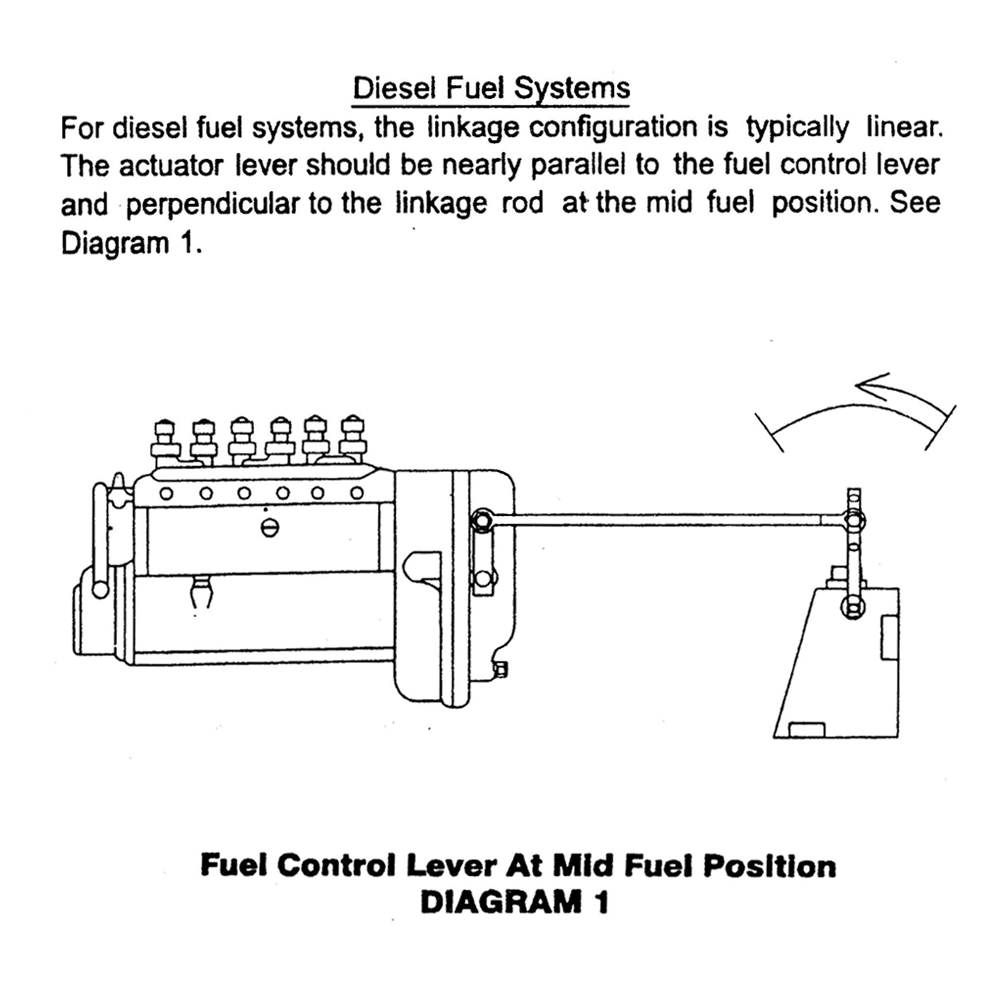

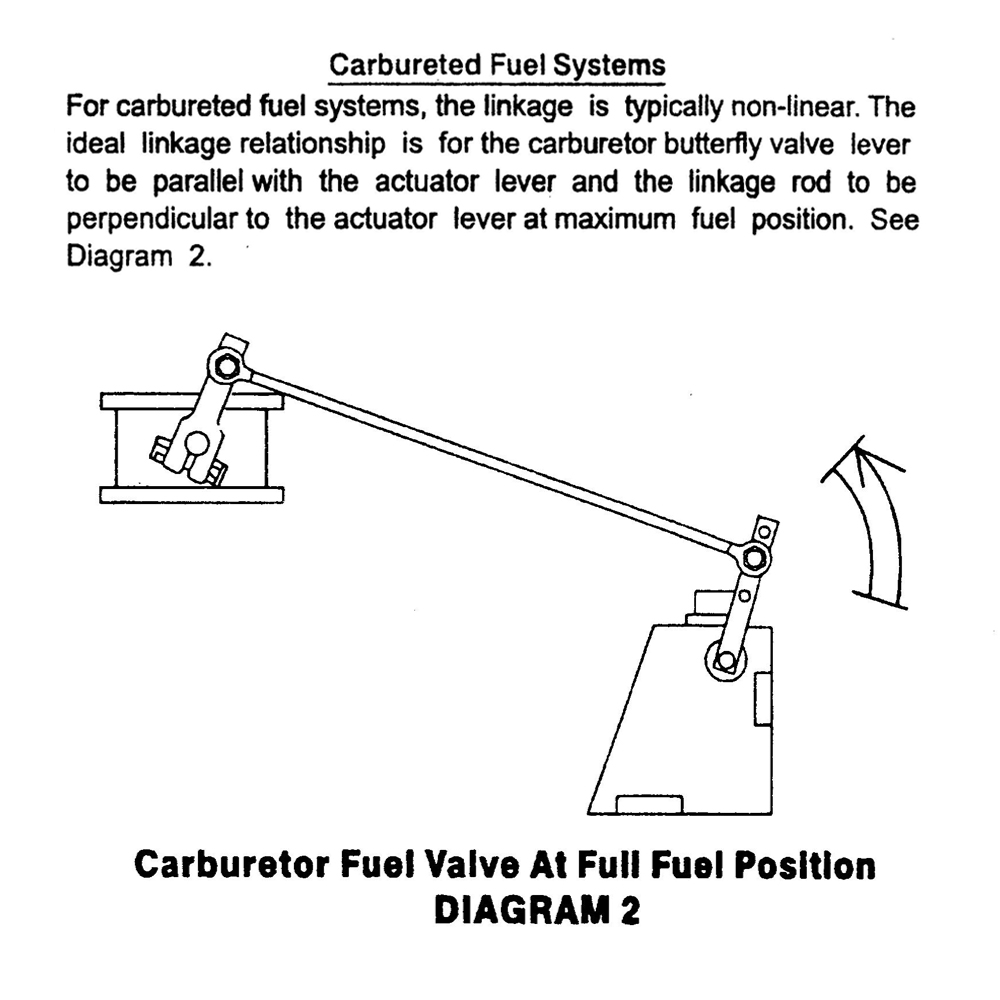

1.The actuator must be rigidly mounted as close as possible to the engine throttle lever. When selecting the mounting location, consideration must be given to possible linkage obstructions。

2.The linkage should be direct, short, and as light as possible. Low friction rod end bearings should be used throughout the linkage system.

3.T he linkage should be adjusted so that the fuel control minimum fuel and maximum fuel stops are used rather than the internal actuator stops.

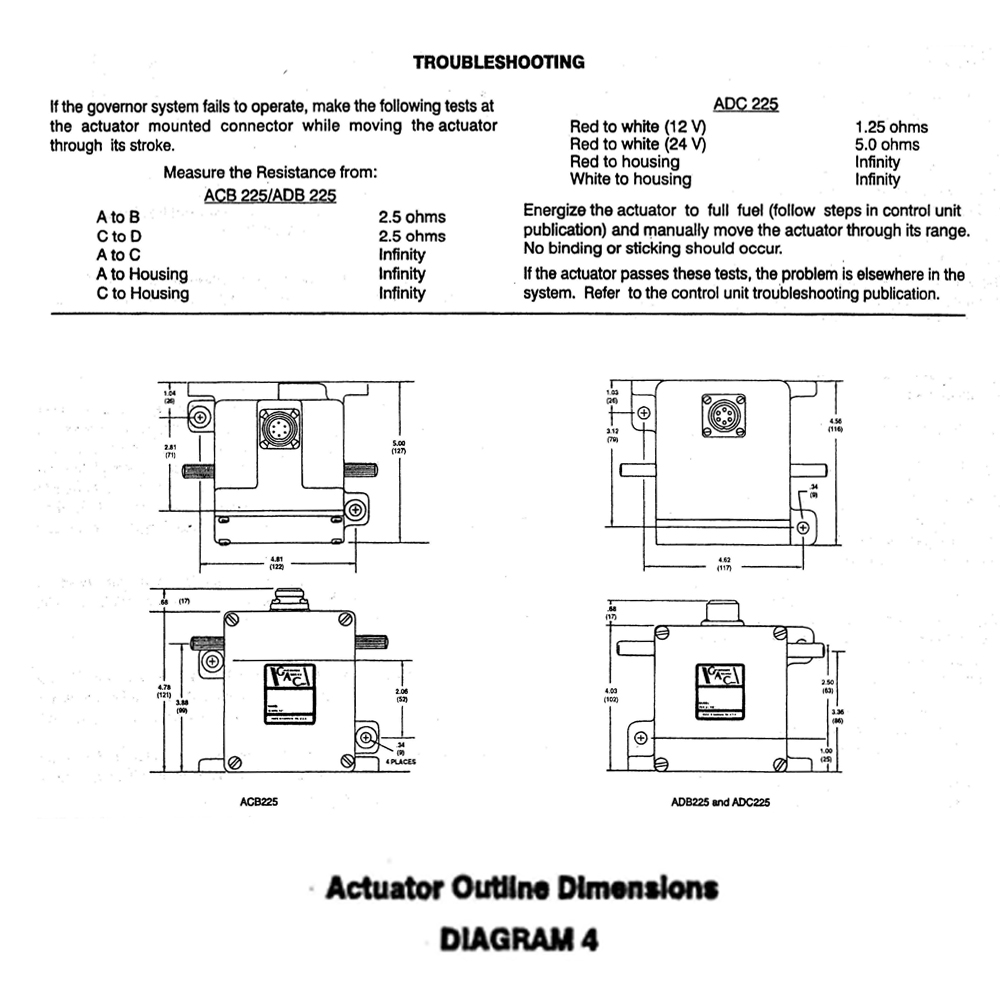

4. A. Drill the actuator mounting holes in a pre-fabricated mounting bracket. Mounting hole configuration is illustrated in Diagram 4.

The position of the actuator on the mounting bracket should insure minimal misalignment between each end of the governor system linkage. The linkage ball bearing rod ends can tolerate a maximum misalignment of 10 degrees.

B. Affix the actuator bracket to the selected location on engine.

C. Attach the actuator securely to the mounting bracket

D. Adjust and secure the linkage rod and rod end bearings.

For proportional actuators to operate with linear control system sit is important to obtain a linear relationship between actuator stroke and fuel delivery.

Package List:

1 x Actuator Set

Note: 12V or 24V optional, 12V pull: about 1kg, 24V pull: about 1.5kg.