| Quantity | 3+ units | 10+ units | 30+ units | 50+ units | More |

|---|---|---|---|---|---|

| Price /Unit | $20.98 | $20.55 | $19.91 | $19.05 | Contact US |

New Original 6ED1055-4MH08-0BA1 Text Display LOGO TDE 24VAC/DC 12VDC with 128x64 LCD for SIEMENS

$138.36

New Original 6ED1055-4MH08-0BA1 Text Display LOGO TDE 24VAC/DC 12VDC with 128x64 LCD for SIEMENS

$138.36

HO3507 ST-ST-ST HOLLOW 40-24-11 Hollow Servo Motor w/ 0.08N.M Rated Torque for Industrial Automation

$126.01

HO3507 ST-ST-ST HOLLOW 40-24-11 Hollow Servo Motor w/ 0.08N.M Rated Torque for Industrial Automation

$126.01

MS4005 V3 Servo Motor BLDC Motor (RS485 18bit & Not Through Slip Ring) for Mechanical Arms & UAV PTZ

$64.45

MS4005 V3 Servo Motor BLDC Motor (RS485 18bit & Not Through Slip Ring) for Mechanical Arms & UAV PTZ

$64.45

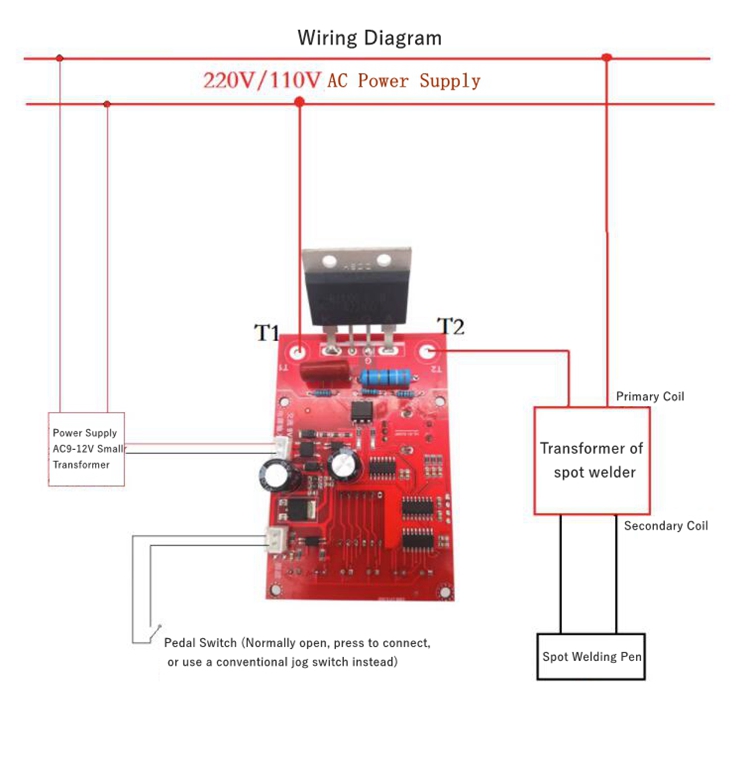

NY-D02 100A High Precision Double Pulse Encoder Spot Welding Transformer Control Board Current Time Control Board

Read Before Purchasing:

- Basic knowledge of electronic and electrician is highly recommended. We do not provide full installation guidance throughout the entire process.

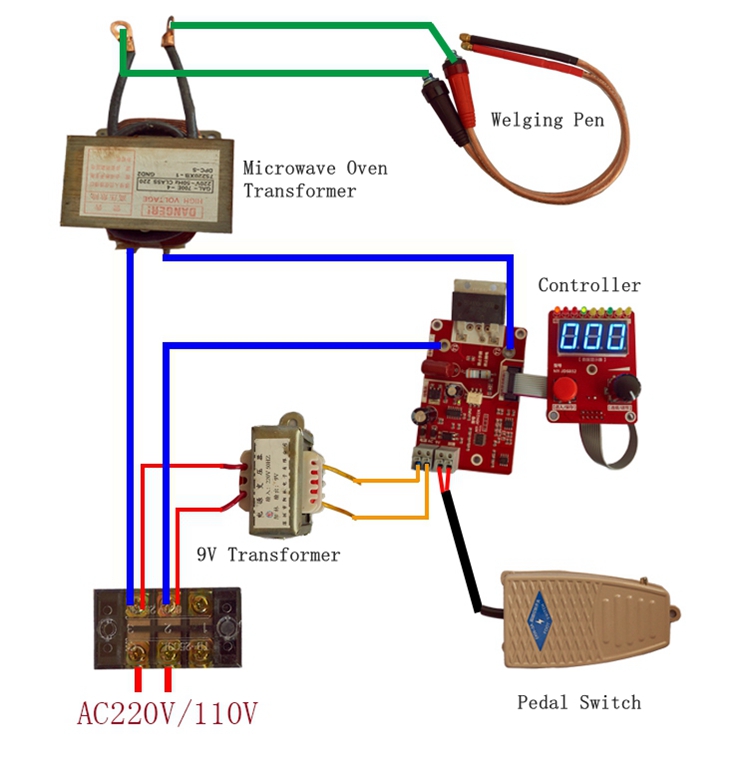

- Only a piece of controller board pictured is included. Other accessories and transformers are not included. The board is an AC transformer control board, and it cannot be used as a control board for double-layer capacitor energy storage.

Version Introduction:

- 100A: It is designed with a 100A SCR.

How To Choose The Versions You Want?

- The board of this model can be matched with SCRs with two currents. The 40A version can connect to a microwave oven transformer. The 100A version can connect to two microwave oven transformers. Users who use ring-shaped transformers are recommended to use the 100A ones. Users use transformers with unknown transformers please use this version.

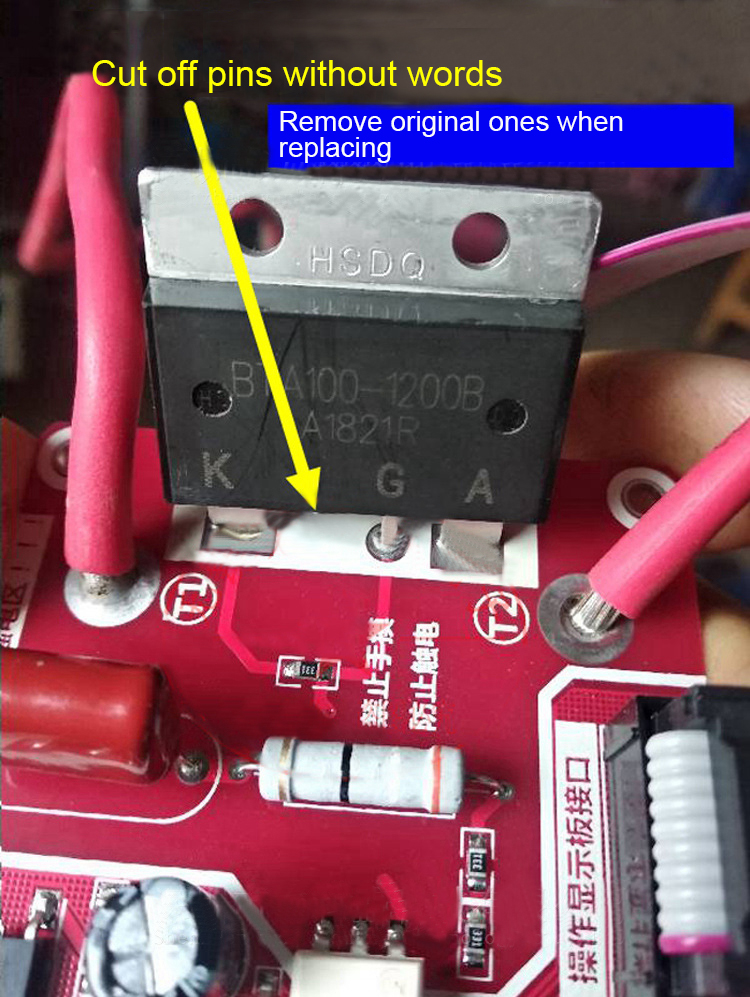

- 40A and 100A SCR can be directly replaced with each other, and the user does not need to change the size of the absorption RC. The board design is compatible with 40A and 100A.

- About SCR: Premium Chinese SCRs are used. It is effective for DIY.

Annotations on Vocabulary Terms:

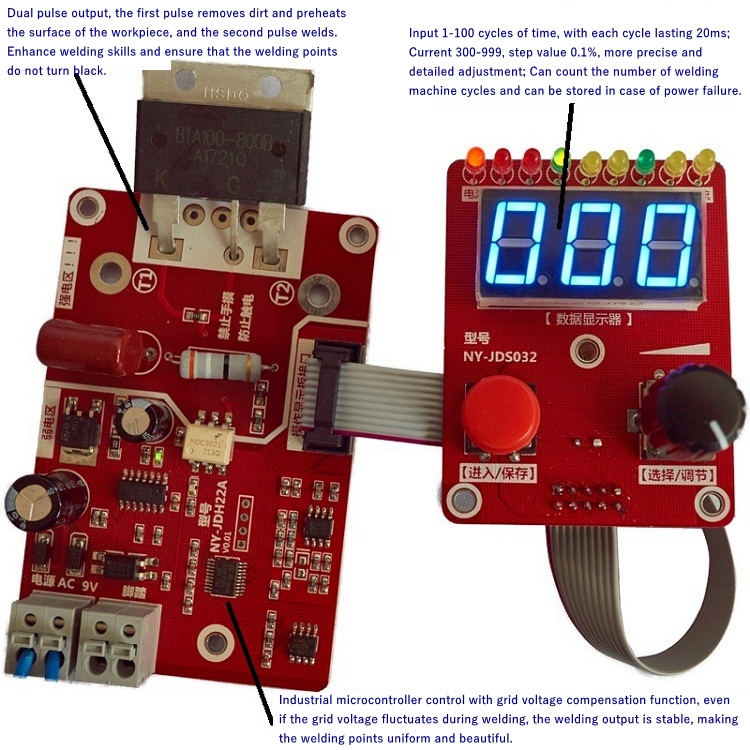

- Time current: The unit of time is in cycles, with one cycle lasting 20 milliseconds, 1-50 seconds, or 0.02-1s; The unit of current is permillage, which can be understood as controlling the permillage output of the transformer.

- Double pulse: The first pulse is used for preheating and cleaning, while the second pulse is used for welding. So, double pulse welding will be relatively powerful, and the solder joints will be more beautiful and aesthetically pleasing, generally without blackening. Therefore, when setting the dual pulse parameters, the first current should generally be slightly smaller than the second current in order to fully utilize its significance.

- Voltage stabilization function: When the grid voltage fluctuates, the welding output will also fluctuate accordingly, which can cause uneven welding points, and even solder through or failure to solder. Simply put, voltage stabilization is to stabilize the voltage, so that the welding output is uniform and the solder joints are also uniform and beautiful, without causing waste.

- Power-off saving: If there is a sudden power outage and shutdown during the welding process, the welding parameters will be automatically saved. After the next startup, it can be used directly without the need for re debugging.

- Welding specification: refers to the combination of welding parameters corresponding to different welding materials. Our D03 model can store 5 sets of welding specifications at the same time. If you have different material requirements for welding (including thickness, material, etc.), you can choose D03 model without having to go back and forth for debugging, just call the parameters directly.

Specifications:

- Model: NY-D02

- Power supply: AC 9-12V, 3W, 50Hz/60Hz (AC power supply is required)

- Start mode: pedal or other passive normally open point (must be a normally open point)

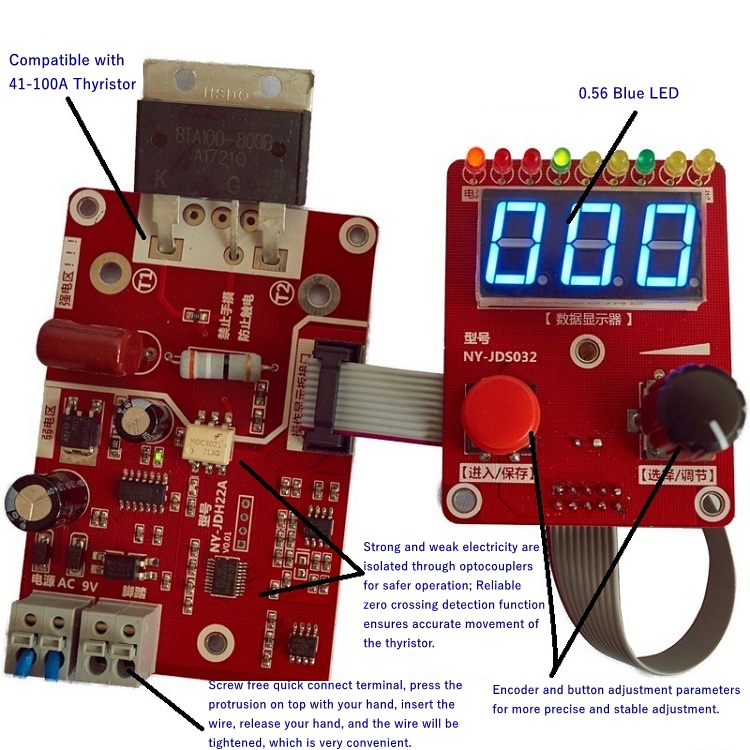

- Trigger form: imported optocoupler for SCR

- Display form: 0.56-inch digital tube

- Adjustment method: potentiometer/knob

- Time range: 1-99

- Current range: 300-999

- Welding output: double pulse

- Voltage stabilization function: yes

- Counting function: yes

- Save when power off: Yes

- Number of standard groups: 1 group

- Drive thyristor: bidirectional thyristor, 100A and below, can drive a G-level. Connection to external thyristor modules is prohibited. Items come with SCR.

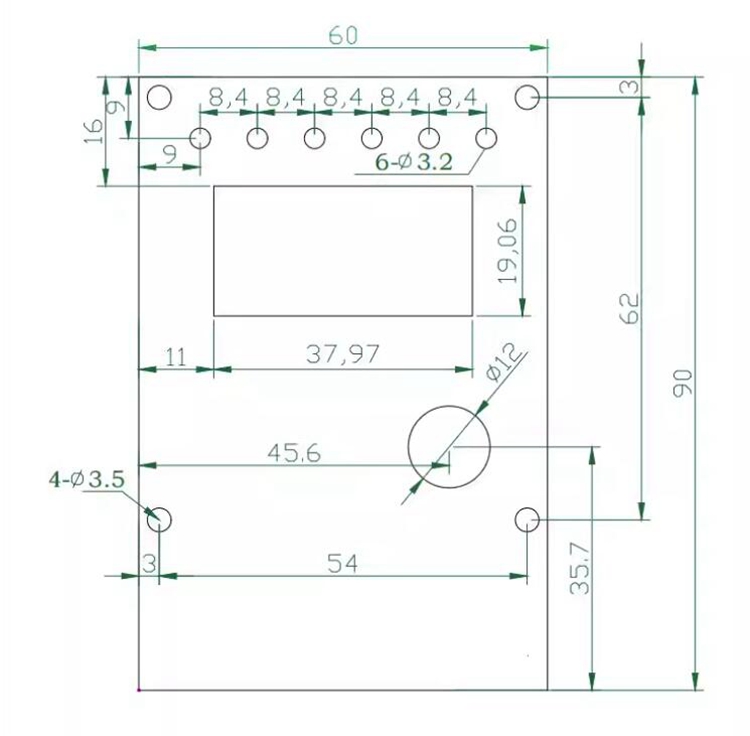

- Main board PCB size: 148*87MM (The height of the device changes due to plug wire and thyristor, so its thickness is not mentioned above)

Package Included:

- 1 x Set of Spot Welder Controller Board

Operation Instruction:

Panel Indicators:

- Power supply: red; system power supply, normally on.

- Foot pedal: red; when the foot switch is closed, this light is on.

- Trigger: red; when the thyristor is triggered, this light is on for the same duration as the welding time.

- Operation: green; when welding is allowed, this light remains on continuously; When setting parameters, this light goes off.

- Time: yellow; first pulse welding time.

Running: first pulse synchronous lighting up.

Parameter query: when this light is on, the LED displays the current set welding time value.

Parameter setting: This light is on, the LED flashes, and the current value is modified through the encoder.

- Current: yellow; first pulse welding current.

Running: first pulse synchronous lighting up.

Parameter query: when this light is on, the LED displays the current set welding current value.

Parameter setting: when this light is on, the LED flashes. Modify the current value through the encoder.

- Interval: green; the interval time between the first pulse welding and the second pulse welding.

Running: interval status synchronized illumination.

Parameter query: when this light is on, the LED displays the current set interval time value.

Parameter setting: when this light is on, the LED flashes, and the current value is modified through the encoder.

- Time: yellow; second pulse welding time.

Run time: the second pulse synchronously lights up.

Parameter query: when this light is on, the LED displays the current set welding time value.

Parameter setting: when this light is on, the LED flashes, and the current value is modified through the encoder.

- Current: yellow; second pulse welding current.

Run time: the second pulse synchronously lights up.

Parameter query: when this light is on, the LED displays the current set welding current value.

Parameter setting: This light is on, the LED flashes, and the current value is modified through the encoder.

Display Status:

- This controller has three operating states: welding preparation, parameter query, and parameter change

1: Welding preparation: the running light is always on, and the time, current, interval, time, and current indicator lights are off.

2: Parameter query: running indicator light off, time, current, interval, time, current corresponding indicator light quantity, digital tube constantly on, displayed value is the corresponding parameter value

3: Parameter change: the running indicator light is off, and the corresponding indicator lights for time, current, interval, time, and current are displayed. The digital tube flashes, and the displayed value is the corresponding parameter value change value.

Welding Preparation:

- By selecting/adjusting the encoder to rotate counterclockwise, keep the running light on and the time, current, interval, time, and current indicator lights off. At this time, welding can be performed, and the value displayed on the digital display is the current welding count value

Voltage Calibration:

- Due to the network voltage compensation function of this controller, voltage calibration is required for the first installation, and only one calibration is needed. (In the future, as long as the power transformer is not replaced, there will be no need to calibrate it again)

- Calibration operation: when in operation, long press the micro switch until the time, current, and interval lights are all on. At this time, use a multimeter to measure the mains voltage. For example, if the measured voltage is 225V, rotate the encoder to display the value of 225 on the LED. Then double-click the micro switch to exit calibration.

Parameter Changes:

- When querying parameters, rotate the encoder through [Select/Adjust] to query. When the indicator light is on, the LED displays the current parameter value corresponding to the parameter.

- For example, if you rotate [Select/Adjust] to turn on the interval indicator light, the value displayed on the digital display will be the interval time.

Counting Zeroing:

- This controller has a welding counting function, which automatically increments the welding count by 1 for each welding operation. Count range 0-999.

- If you want to reset, double-click the [Enter/Save] button while running, and the count will automatically reset to 0.

Precaution:

- After installing the system, be sure to check the setting parameters first. The current time should start from the minimum gear and increase it step by step.

- In general, a 1.5mm small needle cannot last for 0.1 seconds (equivalent to the number of cycles on this board, which is a total of 5 cycles, each cycle lasting 20 milliseconds). If it is not firmly connected, the only way is to increase the current, not to add time indefinitely! If someone doesn't spot weld batteries and wants small hardware, please use a 3MM tapered needle that can carry a relatively large current.

- After receiving the product, do not install the machine or connect the large transformer first, and do not install it into the machine casing without lighting it up. You should first connect a 9V-12V small AC power supply (the microwave oven transformer does not need to be connected), light up the board first, test the function display and adjustment, and then replace the silicon or install it in the shell.

- The general usage parameters of this board (in fact, there are no general ones, specific adjustments can be made according to the specific situation. The following parameters are mainly for customers who have just installed and do not know how to set the parameters. There is a central range value, which can be gradually adjusted according to the specific situation later): the first pulse time is 001 and the current is 800; Interval 001-003; The second pulse 002-003 has a current of 999. 003 is three 20 millisecond pulses of 60 milliseconds. We suggest that the total time should not exceed 003, and the limit should not exceed 005 (0.1 seconds). If exceeded, the nickel sheet will change color, and the soldering needle will stick and change color.