| Quantity | 3+ units | 10+ units | 30+ units | 50+ units | More |

|---|---|---|---|---|---|

| Price /Unit | $19.33 | $18.93 | $18.34 | $17.55 | Contact US |

2-Meter IEEE-488 Connection Cable GPIB Industrial Level Data Cable for Industrial PLC Control Board GPIB Transmission

$22.02

2-Meter IEEE-488 Connection Cable GPIB Industrial Level Data Cable for Industrial PLC Control Board GPIB Transmission

$22.02

XSB9 Handheld Force Gauge Digital Force Gauge + DYMH-103 Miniature Load Cell Sensor (0-200KG)

$168.45

XSB9 Handheld Force Gauge Digital Force Gauge + DYMH-103 Miniature Load Cell Sensor (0-200KG)

$168.45

XSB9 Handheld Force Gauge Digital Force Gauge + DYMH-103 Miniature Load Cell Sensor (0-100KG)

$168.45

XSB9 Handheld Force Gauge Digital Force Gauge + DYMH-103 Miniature Load Cell Sensor (0-100KG)

$168.45

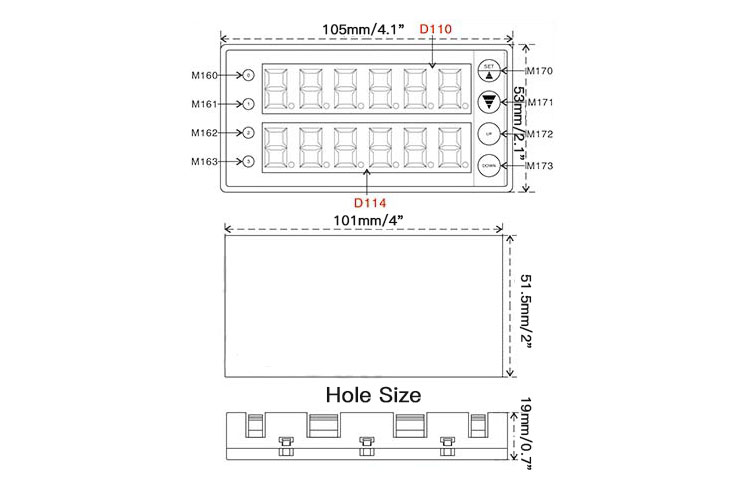

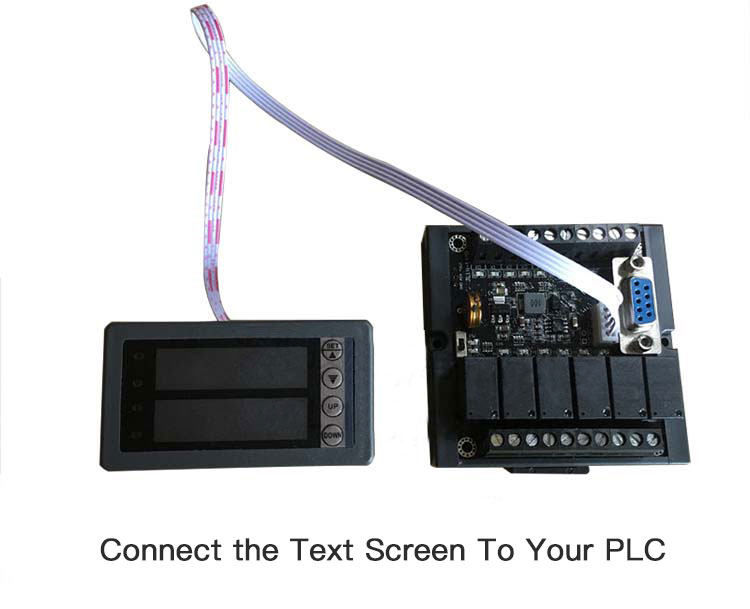

PLC Display PLC Screen Input Parameter Display Board Equivalent To Text Touch Screen No Programming

Description:

The display can be used with PLC made by JLING. It is cost-effective and can be used to replace touch screen and text display in small devices. In many projects, it can also replace the development of single-chip microcomputer, with short development cycle, mature circuit, stable and reliable performance. You can also use our digital tube display board to replace counters and timers. You can flexibly program PLC according to your own use place to adapt to different requirements, enabling flexible applications.

Features:

- 0.56 digital tubes used

- Clearer display

- Simple text

- No programming required

- Install to use

- Smooth buttons and thinner body

Package Included:

- 1 x Set of Display Screen

Note:

- PLC is not included.

Instructions:

There are two modes. One is the main mode and the other is the parameter mode.

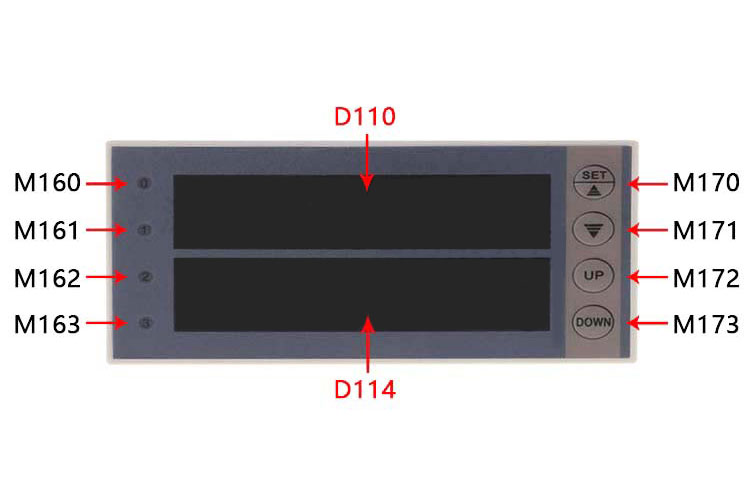

1. Enter the main mode as soon as the power is turned on. In this mode, the upper row of digital tubes displays the value of D110, and the lower row of digital tubes displays the value of D114. The button switch controls the closing and opening of the corresponding intermediate relay (M), and the indicator light is controlled on and off according to the closing and opening of the internal intermediate relay (M). Press and hold the SET key for 3 seconds to enter the parameter input mode.

2.In the parameter input mode, the value of the data register D200 and later can be changed. The upper row of digital tubes is used to display the number of the data register to be changed. Press the upper triangle key (increase) or press the triangle key (decrease) to change the number. When changing, the read value will be displayed on the lower row of digital tubes, and the value can also be changed by using the UP key and DOWN key.

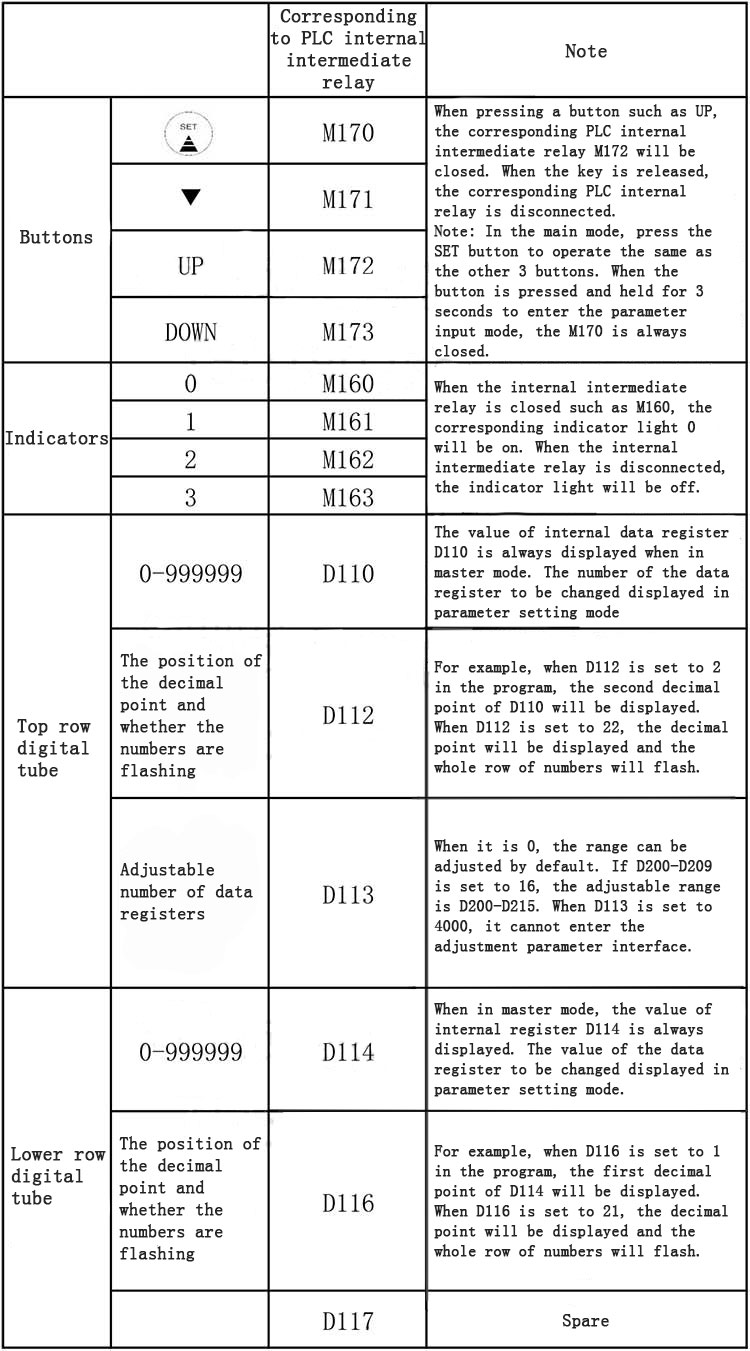

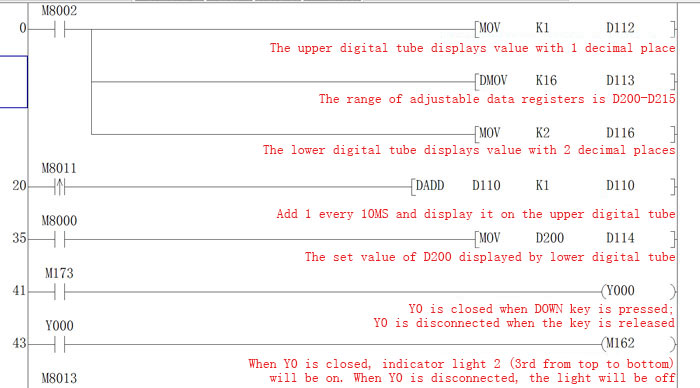

This display board occupies the following resources of PLC, please pay attention to PLC programming: