| Quantity | 3+ units | 10+ units | 30+ units | 50+ units | More |

|---|---|---|---|---|---|

| Price /Unit | $46.42 | $45.48 | $44.05 | $42.16 | Contact US |

ZM-3H2080 24V High Performance 3-Phase Stepper Motor Driver Controller AC80-220V for 86-130MM Stepper Motors

$166.32

ZM-3H2080 24V High Performance 3-Phase Stepper Motor Driver Controller AC80-220V for 86-130MM Stepper Motors

$166.32

ZM-3H2080 12V High Performance 3-Phase Stepper Motor Driver Controller AC80-220V for 86-130MM Stepper Motors

$166.32

ZM-3H2080 12V High Performance 3-Phase Stepper Motor Driver Controller AC80-220V for 86-130MM Stepper Motors

$166.32

ZM-3H2080 5V High Performance 3-Phase Stepper Motor Driver Controller AC80-220V for 86-130MM Stepper Motors

$166.32

ZM-3H2080 5V High Performance 3-Phase Stepper Motor Driver Controller AC80-220V for 86-130MM Stepper Motors

$166.32

RTM5740 50VDC 4A 128 Subdivision Microstep Driver Stepping Motor Driver CNC

Brief introduction:

RTM5740 driver, 2-phase stepper motor drives, suitable for driving small and medium-sized phase current is less than 4A 2-phase or 4-phase hybrid stepping motor. Due to the adoption of the new bipolar constant current chopper drive technology, using the same motor can output more speed and power than other drivers. Segments stepper motor running accuracy improved, reduces vibrations and noise reduction.

Features:

1)High-performance

2)Bipolar constant current chopping mode

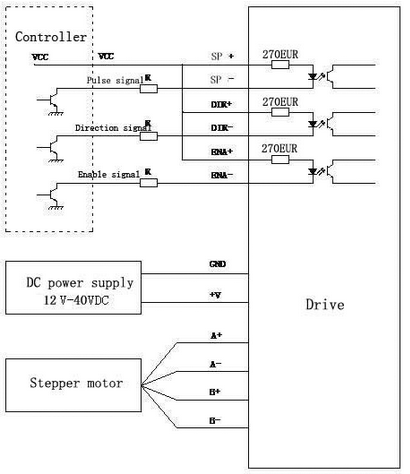

3)Power supply voltage 12 to 40VDC

4)High-speed optocoupler signal isolation input

5)20kHz chopping frequency

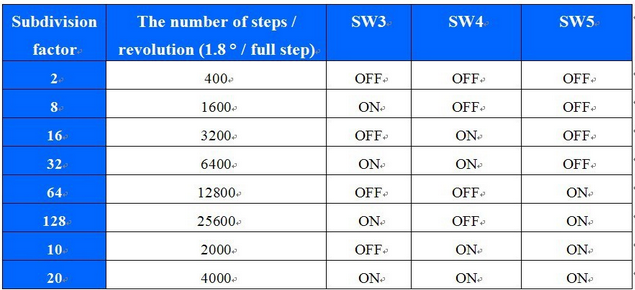

6)Subdivision precision 2\8\16\32\64\128\10\20 optional

7)Electrical input signal is TTL compatible

8)Stationary current is automatically reduced by half

9)Shape design is convenient for installation

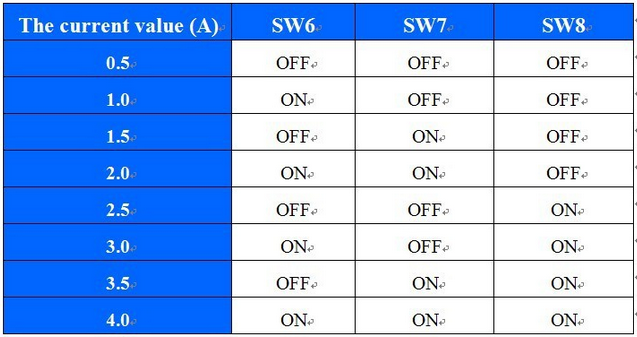

10)Maximum drive current is 4A

11)Drive any 4A phase current of 2-phase or 4-phase hybrid stepping motor

Applications:

Suitable for a variety of small and medium-sized automation equipment and instruments,for example: Small engraving machine, SMT machine, etc

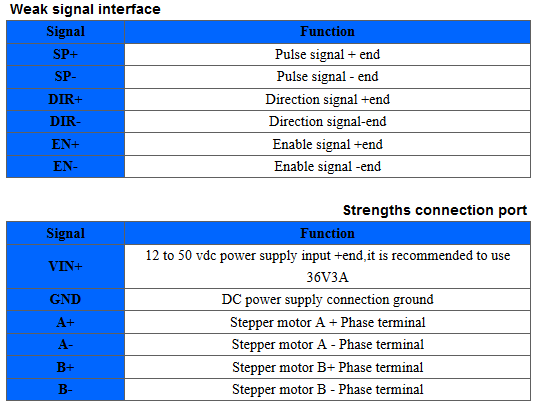

Wiring defined:

NOTE: This driver does not contain anti-anti-interpolation circuit so non-input positive and negative power supply upside down! Otherwise it will damage the drive

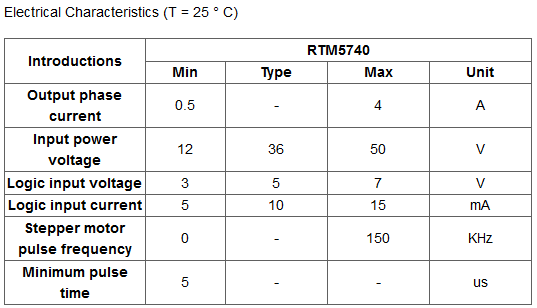

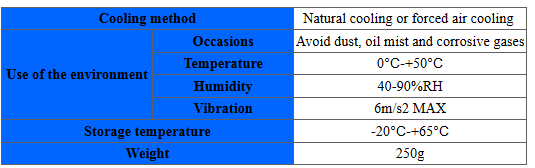

The use of the environment and parameters:

Power supply:

The supply voltage can work normally in between DC12V-50V, RTM5740 driver can use ordinary switch DC power supply, can also be used for transformer and the bridge rectifier and filter capacitor, capacitance desirable 2000U to 5000U. Note rectified voltage ripple crest does not exceed 50V.Recommended the user to use the 24V-32V DC supply , avoid the grid fluctuations over drive voltage operating range.

Note:

1, Wiring should pay attention to the power of positive and negative Do not be reversed;

2, In order to reduce costs, multiple drives can share a power supply. But it should improve the rated power and rated output current of the power and attention to cooling.

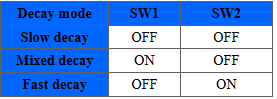

DIP switch settings:

Subdivision DIP switch settings:

Current DIP switch settings:

Drive motor controller wiring diagram:

Electrical wiring:

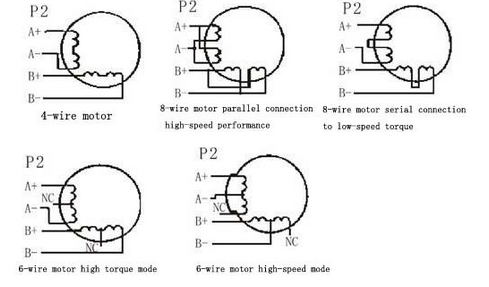

The RTM5740 driver can drive all current 4A 4-wire, 6-wire or 8-wire 2-phase / 4-phase motors, are detailed below 4-wire, 6-wire, 8 wire stepper motor connection:

Matching of the drive and motor

RTM5740 driver can drive the domestic and foreign manufacturers of 2-phase or 4-phase motor, in order to obtain the most satisfactory driving, you need to choose a reasonable supply voltage and current setting. Supply voltage determines the level of the high-speed performance of the motor, and the current set value determines the output torque of the motor.

Supply voltage selected

Generally speaking, the higher the supply voltage, the greater the torque motor at high speed, the more it can avoid the high speed out. But another aspect, the voltage is too high will lead to over-voltage protection, and can even damage the drive, but also in the high-pressure work, low speed vibrations.

The output current is set

For the same motor, the greater the current setting, the higher speed, the current motor and drive more heat. So under normal circumstances the current setting into a powered machine warm but not too hot long-term value.

Note: the current settings after you run the motor for 15-30 minutes, if the motor temperature is too high, you should reduce the current settings. If the motor current setting, the motor output torque is not enough to improve heat dissipation conditions to ensure that the motor and drive are not hot.

Package include:

- 1 x RTM5740 Stepper Motor Driver