| Quantity | 3+ units | 10+ units | 30+ units | 50+ units | More |

|---|---|---|---|---|---|

| Price /Unit | $561.46 | $550.00 | $532.82 | $509.90 | Contact US |

AVC118 Plasma Arc Voltage Height Controller Arc Voltage Height Control for Stepper/Servo Motors

$337.00

AVC118 Plasma Arc Voltage Height Controller Arc Voltage Height Control for Stepper/Servo Motors

$337.00

AVC118 Plasma Arc Voltage Height Controller Arc Voltage Height Control Used to Control DC 24V Motor

$298.14

AVC118 Plasma Arc Voltage Height Controller Arc Voltage Height Control Used to Control DC 24V Motor

$298.14

Wecon IN1101 10.1" 1024x600 Human Machine Interface HMI Display Touch Screen with Ethernet Interface

$117.65

Wecon IN1101 10.1" 1024x600 Human Machine Interface HMI Display Touch Screen with Ethernet Interface

$117.65

SF-2300S-BG Cutting Machine Controller CNC System for Tube Intersecting Line Plasma Cutting

Description:

The cutting machine CNC system is applicable to all kinds of flame and plasma, high pressure water jet, laser cutting machine, and it is widely used in metal processing, advertising, stone and other industries.

Features:

-The system has high reliability design, with anti plasma interference, anti-lightning and surge capacity.

-It can be used in practical flame and plasma cutting process, plasma processing, automatic corner speed control.

-It has breakpoint recovery, automatic power outage recovery function, automatic memory

-It has arbitrary selections and selection of perforation point processing, processing can be arbitrary skip processing.

-It has the function of the extension and perforation of thick plate, and the bridging function is suitable for the thick plate.

-It has regression, excerpts, breakpoint recovery, optional position and other functions, greatly facilitate the user's control.

-It can transfer cut at any time, choose the starting point processing, processing can be automatically broken.

Main Screen Button Description

【F1】-【F8】: Function keys, under different interface, with the corresponding prompt functions; 【F+】: to speed up the speed;

【F-】: to slow down speed;

【S+】: Torch up key;

【S-】: Torch down key;

Under the main interface, the key functions are as follows:

【F1】Gallery: enter the graphics library, most of which are available in sheet size and hole size. You can also enter the nesting screen.

【F2】 File: select local file, U disk file, file edit, file delete, file import export and other operations.

【F3】Part options: mirror, rotate, starting point, rotate correction, scale, segment selection, etc.

【F4】Process parameters: all parameters can be set here.

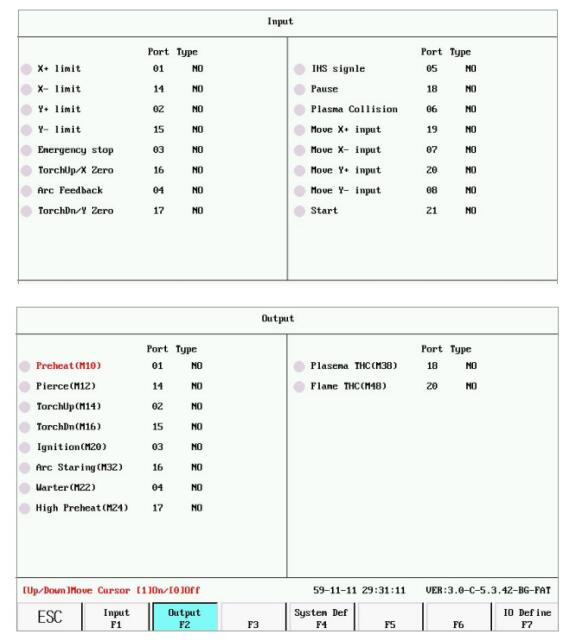

【F5】Diagnostic Settings: input/output diagnostics, system Settings, port customization, etc.

【F6】Graphic information: enlarge graphics, view punch points, and cut information display.

【F7】Manual: manually move the machine tool, reset system coordinates, return parameters, and select breakpoints.

【G】Set cutting mode: press this button to switch the three modes of flame, plasma and demonstration.

【X】Manual speed: sets the manual movement speed.

【F】Cutting speed: set the automatic cutting speed.

【T】Preheating time: set the preheating delay.

【N】Slot: the slot size can be set before the cutting operation starts.

【0】Continuous walk: after the function is turned on, press the direction button when manually moving the gun, the cutting gun will keep walking, and then press the direction button or pause button again to stop.

【Start button】Start cutting;

【Pause key】Pause or stop cutting.

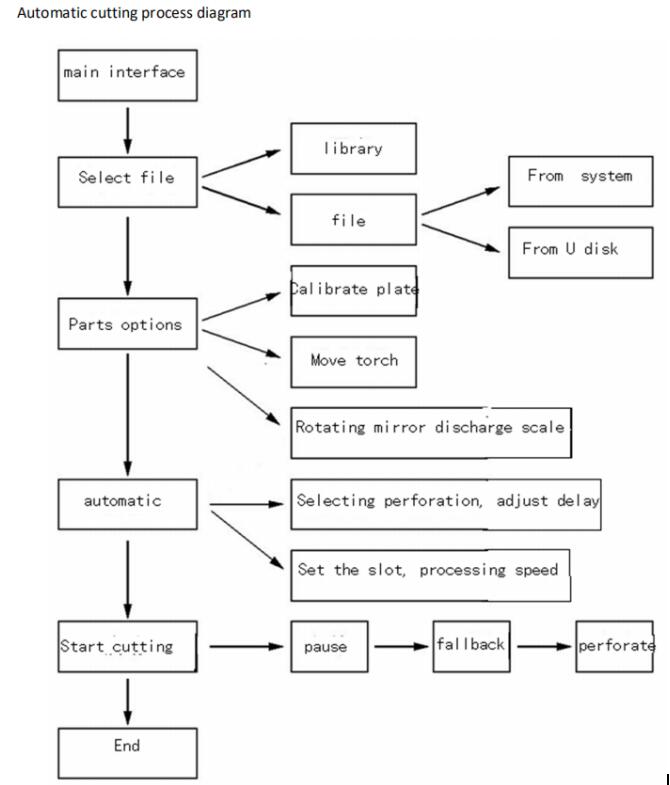

Cutting Process

Wiring Instructions

Package List:

1 x Cutting Machine Controller