| Quantity | 3+ units | 10+ units | 30+ units | 50+ units | More |

|---|---|---|---|---|---|

| Price /Unit | $12.00 | $11.75 | $11.38 | $10.89 | Contact US |

40W Intelligent Adjustment Air Pump Fixed Focus Laser Cutting Machine High Power Laser Engraving Machine

$230.77

40W Intelligent Adjustment Air Pump Fixed Focus Laser Cutting Machine High Power Laser Engraving Machine

$230.77

High Precision Bench Drill 60x60mm Slide Table Repair Fixture Multifunctional Repair Tools for Watch/Clock Maintenance

$205.99

High Precision Bench Drill 60x60mm Slide Table Repair Fixture Multifunctional Repair Tools for Watch/Clock Maintenance

$205.99

High Precision Bench Drill 40x40mm Slide Table Repair Fixture Multifunctional Repair Tools for Watch/Clock Maintenance

$192.71

High Precision Bench Drill 40x40mm Slide Table Repair Fixture Multifunctional Repair Tools for Watch/Clock Maintenance

$192.71

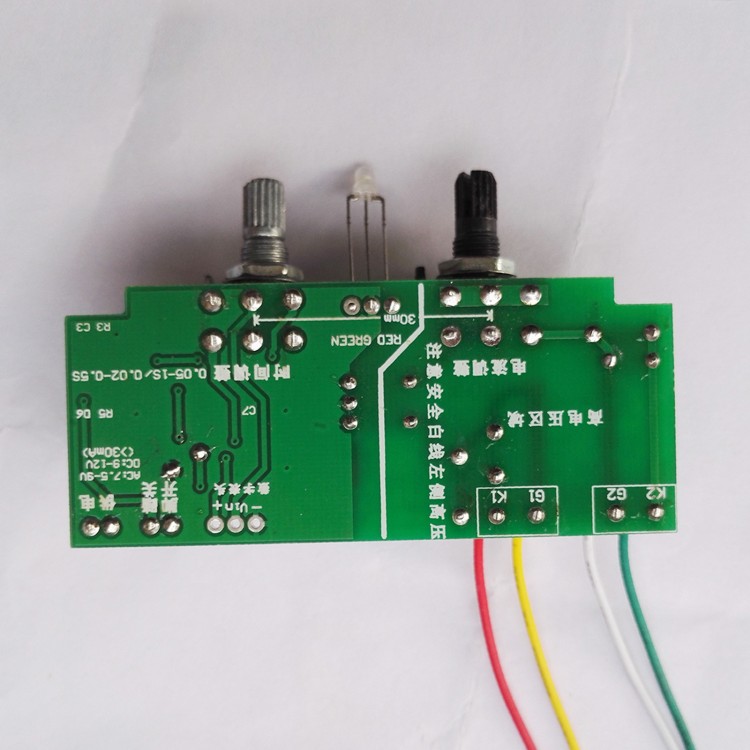

Spot Welding Controller Board Spot Welder Controller Dedicated Drive Board Perfect For SCR Module

Read Before Purchasing:

1. Only a drive board is included. SCR module pictured is not included, please purchase separately.

2. Please connect according to the wiring diagram printed on the board.

3. If you want to buy 70A-200A SCR modules, please contact us so we can connect the board and the module before delivery.

4. SCR modules generally short-circuit terminals 2 and 3 as a contact, and then together with terminal 1 as the two contacts of switch to control your spot welder transformer. A resistance-capacitance absorbing element should be connected in parallel between the two contacts to absorb peak voltage.

Description:

When DIY spot welding machines, time switch control is an important part. Our integrated thyristor control board is popular with users thanks to its low price and simple use. The control board uses BTA100, and at the same time some control boards to promote solid state relays have been made to meet the different needs of users as much as possible. For refitting high-power spot welding machines or using dual transformers to make spot welders, due to the maximum primary current often reaching 40A-50A, even if a 100A thyristor control board is used, it cannot be used, so it is recommended to use a control board to drive high current solid state relay. But there is no function to adjust the current. After a period of trial, the control board designed by us has reached the expected design effect, that is, when users replace SCR modules with different current, the control board can adapt to different transformers.

Similarities When Compared With Onboard SCR Integrated Control Board:

1. Pre-drive circuit, time control method and current adjustment way are the same;

2. Front-level power supply and foot control switch access mode are the same;

3. SCR control method is the same. It is connected in series to the primary control of spot welder transformer;

4. The layout of potentiometer and LED indicator can be changed without changing the panel.

Differences When Comparted With Onboard SCR Integrated Control Board:

1. Thyristor module and the control board are separated, and use a flat cable to connect the two. Users can purchase additional SCR modules with different currents.

2. Use one-way dual anti-parallel thyristor modules, not the SCR bidirectional thyristor used in an integrated board, the two kinds of thyristors are common and cannot be interchanged.

3. Its overall cost is higher than that of integrated board, and its reliability is better.

Package Included:

- 1 x Spot Welding Controller Board