| Quantity | 3+ units | 10+ units | 30+ units | 50+ units | More |

|---|---|---|---|---|---|

| Price /Unit | $148.40 | $145.37 | $140.83 | $134.77 | Contact US |

BU-5 Bluetooth Module Radio Bluetooth Adapter Unit for Yaesu FTM-150R FTM-510DR Transceiver

$55.79

BU-5 Bluetooth Module Radio Bluetooth Adapter Unit for Yaesu FTM-150R FTM-510DR Transceiver

$55.79

STF10M1000M-25 RF Power Amplifier 10-1000MHz 25W-30W Wideband RF Amplifier without Radiator and Cooling Fan

$490.69

STF10M1000M-25 RF Power Amplifier 10-1000MHz 25W-30W Wideband RF Amplifier without Radiator and Cooling Fan

$490.69

STF10M1000M-25 RF Power Amplifier 10-1000MHz 25W-30W Wideband RF Amplifier with Radiator and Cooling Fan

$543.48

STF10M1000M-25 RF Power Amplifier 10-1000MHz 25W-30W Wideband RF Amplifier with Radiator and Cooling Fan

$543.48

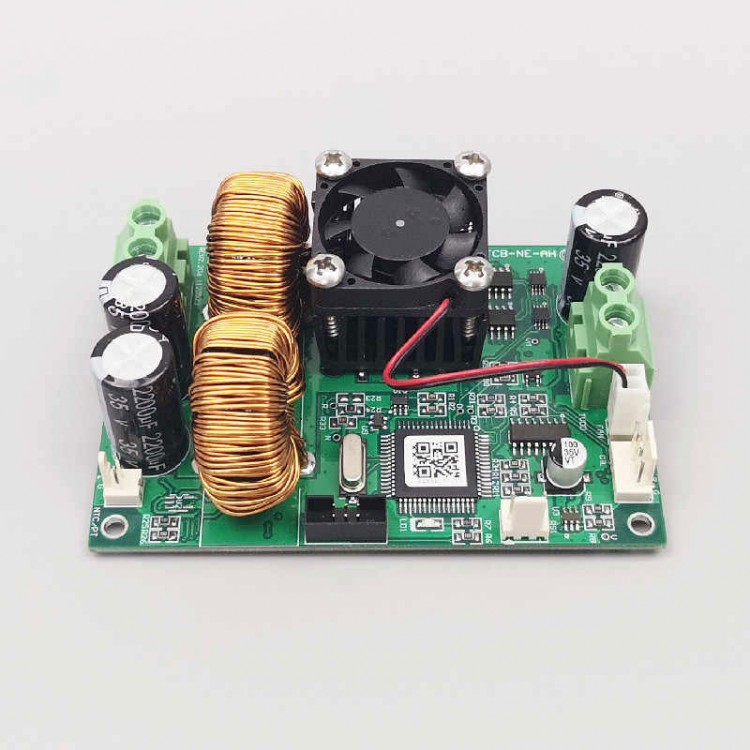

TCB-NE-AH-PT100-4 Thermoelectric Cooler TEC Temperature Control Module Digital PID Controller RS485 Port Support PT100 Probe

About TEC Temperature Control:

- TEC: also known as semiconductor cooling chip or thermoelectric cooling chip, is a semiconductor chip device made by utilizing the Peltier effect, which refers to the unidirectional flow of heat generated when direct current flows through a series of two different semiconductor materials in different directions, thus achieving the purpose of cooling or heating.

- TEC temperature control board: using DC power supply and TEC as the temperature control element, a temperature probe is used to detect the temperature of the controlled object. PID algorithm is used inside the temperature control board to adjust the magnitude and direction of the current provided to the TEC element in real time, thus achieving the purpose of constant temperature.

Features:

- High stability (+/-0.01), universal TEC temperature control, long-term validation in the laser field.

- Bidirectional temperature control, automatic switching between heating and cooling, supporting various types of TECs; It can also be set to unidirectional mode, supporting unidirectional devices such as resistance wires and ceramic heating rods.

- Can run independently. Parameter viewing and setting can be connected to a display screen, or controlled by other microcontroller RS232 serial ports, or using general-purpose serial port software, or dedicated upper computer software.

- Two communication protocols, in addition to the simple ASCII code protocol, also support for MODBUS RTU.

- Support multi-channel control.

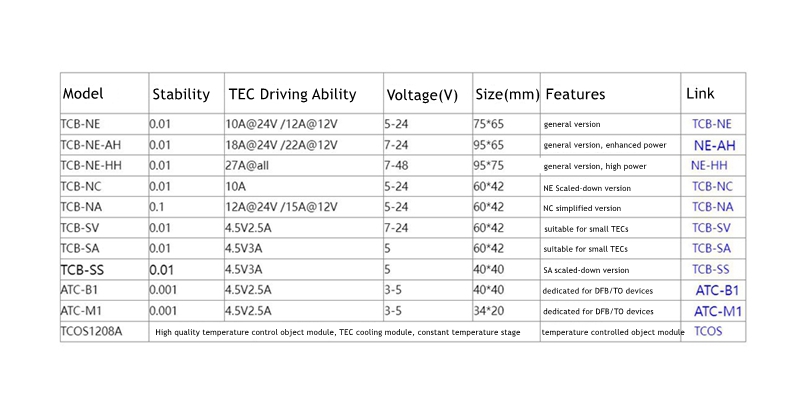

TCB-NE-AH-a-y (model selection):

- a: supported temperature sensor type

Omission: support NTC probe

PT100: support PT100 probe

PT1000: support PT1000 probe

- y: communication interface type

Omission: RS232

4: RS485

- Examples:

TCB-NE-AH: RS232 communication interface, support NTC probe

TCB-NE-AH-PT1000: RS232 communication interface, support PT1000 probe

TCB-NE-AH-PT1000-4: RS485 communication interface, support PT1000 probe

- Note: When the interface is RS232, the board is enabled defaults to automatically sending data when powered on (i.e. the board will continuously send a string of data through the serial port, including temperature, output, and other information). If users need to communicate with the temperature control board through their own host (microcontroller, or PC), it is recommended to send the T0 command and then restart to stop the self sending. Alternatively, they can send the SC command every time they power on to stop the self sending.

- It is recommended to use NTC version, it is cheap and easy to use. PT version can be used in situations with a wide temperature range due to its wide temperature measurement range.

Recommended Application:

- Temperature control system with TEC (semiconductor cooler, thermoelectric cooler) as the temperature control element.

- Suitable for, but not limited to, temperature control of laser diodes.

- Suitable for various fields such as industry and home appliances.

- Biology, medical, PCR temperature control, etc.

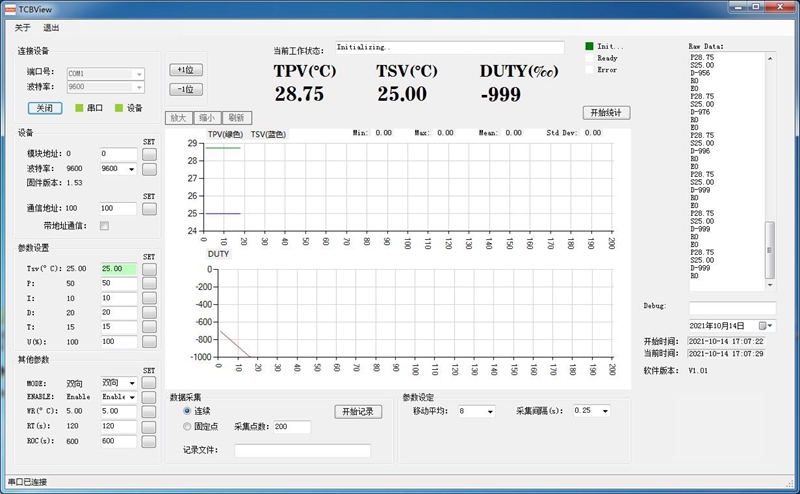

Board Control Method:

- This board uses serial communication to modify and monitor information. There are several control methods:

- Our special display screen DISP-TCB (Connect the serial port of the temperature control board to the display screen); not included.

- Dedicated PC software TCBMate (connect the serial port of the temperature control board to the computer)

- Directly use serial port to send commands to control (single chip microcomputer, or PC), refer to the communication protocol section of the instruction manual.

TCBView new version dedicated PC software (with more powerful functions, can save temperature history data to Excel)

Description:

- The TEC temperature control board is specifically designed for temperature control systems using semiconductor refrigeration chips (TEC), adopting an innovative design scheme that is highly reliable and supports a wide range of TEC voltage and current. The temperature control stability is +/-0.01 degrees! Use serial port to directly modify the set temperature or summon information. Equipped with an alarm ready interface. This board has been widely used in the laser field for a long time. This board is suitable for applications that require high-precision temperature control and high TEC power.

- Digital integral separation PID algorithm with adjustable parameters and cycles. No need for additional heat dissipation measures, no need for a heat dissipation base board.

- Bidirectional control, supporting heating and cooling (can be configured as single heating or single cooling through communication protocol).

- Single heating mode supports heating elements such as ceramics and resistance wires.

- Temperature can be set and detected through serial port (ASCII protocol, guidance document provided).

- Support alarm, ready signal output, and can be disabled TEC output.

Specification:

- Power supply voltage: 7V - 24V (Recommend standard voltages such as 7.5/12/15/24. The rated voltage of the TEC should be equal to or slightly higher than the supply voltage. If the rated voltage of the TEC is lower than the voltage, it is also acceptable to set the output ratio.)

- TEC voltage applicable range: 2V - 24V

- TEC current range: 18A (24V power supply); 22A (12V power supply)

- Temperature sensor: 10K NTC (The default B value is 3950, and the actual B value can be unlimited. It only affects the temperature and does not affect the relatively stable temperature. It is basically meaningless for temperature control. When the B value is 3950, the initial error of the probe itself is not considered, and the measurement error is within 0.1.)

- Temperature control resolution: 0.01°

- Temperature setting resolution: 0.01°

- Stability: +/-0.01°

- NTC version temperature measuring range: -60℃ ~ +170℃

- NTC version temperature control range: -20℃ ~ +100℃ (Actually, it can be set to -50℃~+125℃, but the resolution on both sides will decrease significantly.)

- PT version temperature measuring range: -77℃ ~ +234℃

- PT version temperature control range: -65℃ ~ +225℃

- Working environment temperature: -40℃ ~ +45℃

- Storage environment temperature: -40℃ ~ +60℃

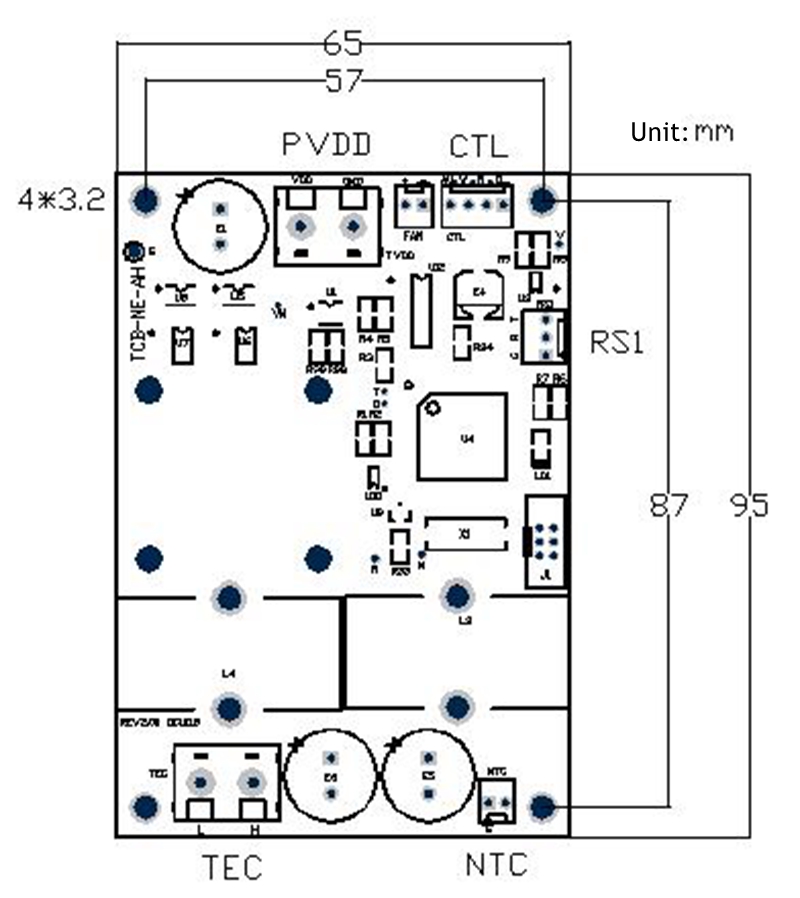

- Size: 65 x 95 x 35mm (Onboard 30mm, board thickness 1.5mm, bottom pins not exceeding 4mm)

Package Included:

- 1 x Temperature Control Board

Note:

- The PT100 probe is not included.

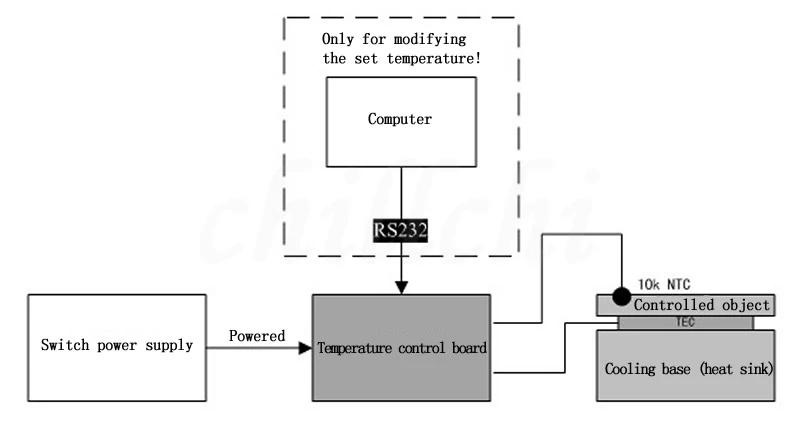

System Diagram:

- As shown in the figure below, to form a complete temperature control system, in addition to the temperature control board, it is also necessary to select the appropriate TEC according to the actual needs of the project. A suitable switch power supply is also needed to provide DC power to the board, and a temperature probe is also required. If it is an NTC version of the temperature control board, we will provide a 10K NTC probe. If it is a PT version, customers need to purchase it by themselves. According to different methods of viewing and modifying parameters, appropriate serial port cables may also be required.

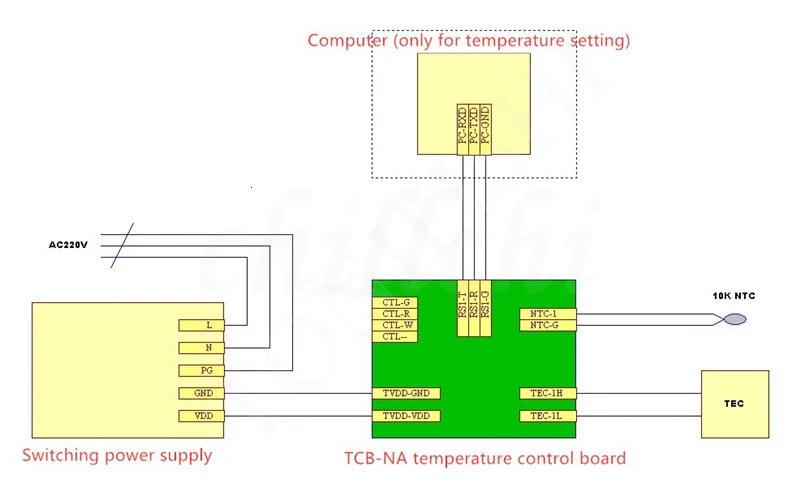

Signal Connection Diagram:

- As shown in the following figure, the connection method of the temperature control board is similar, that is, connecting the probe (the two feet of the probe have no direction), connecting the TEC (the TEC has direction, and there is a description of the connection method), connecting the wires, note that the wires must not be connected back to the serial port control line.

About TEC:

- When considering the current-voltage relationship of TEC, TEC can be simply understood as a resistor, such as a 12V 6A TEC, which can be regarded as a 2 ohm resistor. Then give this TEC 6V drive voltage, its output current is 3A. Limiting the maximum current of the TEC is the same as limiting the maximum voltage. Limiting the maximum driving voltage of the board to the TEC is also equivalent to limiting the maximum current of the TEC. The board has the SU instruction to limit the maximum output voltage (except TCB-NA). TEC can work in parallel or in series. For example, two 12V/4A TECs become 24V/4A in series, and 12V/8A in parallel.

Call information about serial port, set temperature, monitor temperature:

- If you use a computer to view and set the parameters, you need to make a serial cable (available in our shop) to connect to the computer. If your computer does not have a serial port, you need to buy another USB to serial cable. For details, please refer to the description of the document <<Serial Communication Guidelines>>.

About the Interface:

- The manual has detailed interface definitions. The board interface uses 2510 terminals. The manufacturer will provide plugs and ferrules, and no additional purchase is required.

About Stability:

- The stability of temperature control, such as +-0.01, that is, the temperature of the controlled object in the normal system can be stabilized within +-0.01 of the set value. Generally speaking, for temperature control systems, the most important parameter is stability.

- But note that people who have no practical experience in temperature control applications may have deviations in their understanding of stability.

- The temperature control boards of our company have been tested on our load, and the marked accuracy parameters can be confirmed to be achieved, such as +/- 0.01 stability! Note, however, that the nominal rating can be achieved, which does not mean that the customer can simply build a system to achieve it! Because temperature control is a system, the temperature control board is only one of them. For example, the installation method of the probe has a great influence on the temperature control effect. For details, please see the instructions on the product manual and the application data. Another example is the temperature control range, the nominal range of the board, which means the range supported by the board's algorithm, not that it can be achieved with this board. For example, the board's nominal minimum can be controlled to -20 degrees. If the user's TEC power is not enough, or the object design has other problems, such as poor heat dissipation, let alone -20, even 0 degrees may not be reached.

Regarding Temperature Accuracy:

- Accuracy represents the error between the current measured temperature and the absolute true temperature in a physical sense. For general systems, this value is not important, because for example, the currently measured measured temperature is 25 degrees, and the absolute true temperature is 24.5 If the object is stable at the measured temperature of 25 degrees, the object is also stable at the true temperature of 24.5 degrees. This is enough for a general system. As for the current real temperature, it does not matter (for example, for laser applications, it is necessary to adjust to find an optimal temperature to obtain the best output). However, if the temperature measurement accuracy is high, it is also beneficial. One is that some applications may require high accuracy (for example, to achieve a certain temperature scene to measure other characteristics of the object), the other is high The accuracy can realize the interchangeability of the boards, that is, for the same controlled object, even if the temperature control board is changed, as long as it is set to the original setting value, there is no need to find an optimal temperature again.