| Quantity | 3+ units | 10+ units | 30+ units | 50+ units | More |

|---|---|---|---|---|---|

| Price /Unit | $65.79 | $64.44 | $62.43 | $59.75 | Contact US |

FMD Writer MCU Programmer Chip Programmer Tool Designed for 8-bit Microcontrollers Produced by FMD

$60.24

FMD Writer MCU Programmer Chip Programmer Tool Designed for 8-bit Microcontrollers Produced by FMD

$60.24

Matrix:bit V2.0 Development Board Programming Control Board (Pink with Type-C Port) + Data Cable

$21.09

Matrix:bit V2.0 Development Board Programming Control Board (Pink with Type-C Port) + Data Cable

$21.09

Matrix:bit V2.0 Development Board Programming Control Board (Black with Type-C Port) + Data Cable

$21.09

Matrix:bit V2.0 Development Board Programming Control Board (Black with Type-C Port) + Data Cable

$21.09

USBCAN II Industrial High Speed Dual Channel CAN Debugger 8500f/s Support CAN Repeat Offline Sending

Performance Index:

- Compatible with universal USBCAN devices.

- The maximum reception capacity of a single channel is more than 14000 frames/second (test conditions: baud rate 1M, standard frame, 1 byte of data), and the maximum transmission capacity is 3000 frames/second, without crash and frame loss.

- When two channels receive simultaneously, the maximum receiving capacity is 8500 frames/second (baud rate 1M, extended frame, 8 bytes of data).

- Support the CAN relay function, and realize the transparent transmission of data of two CAN channels at different baud rates.

- Intuitive and fast hardware filter settings.

- USB protection and CAN bus protection circuit are added.

- Support for VC++, C #, VB, Labview and other secondary development interface functions.

- The system supports for WIN98, WIN200, XP, WIN7, WIN8, WIN10.

- Support offline automatic cyclic transmission, which can be used as CAN analog transmitter.

- CAN bus baud rate measurement tool software is more accurate and efficient than conventional baud rate identification software.

- CAN data storage, data files can be played back online and sent offline according to time identification or timing.

- CAN data is classified and displayed in the list according to ID.

Features:

- The dual channel USB CAN II debugger has 2 CAN interfaces, and the PC can be connected to a standard CAN network through the USB bus to build a CAN core control unit for data processing, data acquisition, and data communication networks in fields such as fieldbus testing laboratories, industrial control, intelligent buildings, and automotive electronics.

- The dual channel USB CAN II debugger can be used as a standard CAN node and is a powerful tool for CAN bus product development, CAN bus device testing, and data analysis; Meanwhile, the USBCAN debugger has the characteristics of small size and easy installation, making it the best choice for portable system users.

- The dual channel USBCAN II debugger can use the USBCAN tool software provided by our store to directly configure, send, and receive the CAN bus. Users can also refer to the DLL dynamic link library and routines provided by our store to write their own application programs, making it convenient to develop CAN system application software products.

- In the dual channel USB CAN II debugger device, the CAN bus circuit adopts a DC-DC power module and an industrial grade magnetic coupling isolation chip for CAN bus isolation, which makes the interface adapter have strong anti-interference ability and greatly improves the reliability of the system in harsh environments.

Hardware Parameters:

- Protocol conversion between USB and CAN bus.

- The USB interface supports USB 2.0 and is compatible with USB 1.1.

- Supports CAN2.0A and CAN2.0B protocols, standard frames and extended frames.

- Supports bidirectional transmission of 2 CAN channels, CAN sending and CAN receiving.

- Supports data frame and remote frame formats.

- The baud rate of the CAN controller can be selected between 5Kbps and 1Mbps, and a CAN register can be configured to set a special baud rate.

- The industrial grade magnetic coupling isolation chip used in the CAN transceiver has an isolation voltage of 2500V.

- The CAN controller is equipped with 32 hardware FIFO receiving buffers, and the maximum receiving capacity of a single channel can reach 14000 frames per second.

- Direct power supply via USB bus.

- System operating platforms: for WinXP, Win7, WIN8, WIN10.

- Working temperature: -40 ~ 85 ℃

- Shell size: 98 x 78 x 30mm

Application:

- Realize the sending and receiving of CAN bus network through the USB interface of PC or laptop.

- Fast CAN network data collection and analysis.

- USB interface to CAN network interface.

- Industrial field CAN bus communication.

Package Included:

- 1 x USB CAN II Debugger

- 2 x CAN Adapter Board

- 1 x USB Connection Cable

Device Driver:

- The product driver is developed based on Microsoft's WinUSB, which is stable, reliable, and highly compatible. It supports for 32-bit or 64 bit XP, WIN7, WIN8, and WIN10 systems. After successful installation of the driver, the display in the device manager is as shown in the following figure:

New Version of CANMonitor Software Interface:

- The independently developed upper computer software can transmit and receive data through dual CAN channels, meeting the requirements of conventional debugging applications.

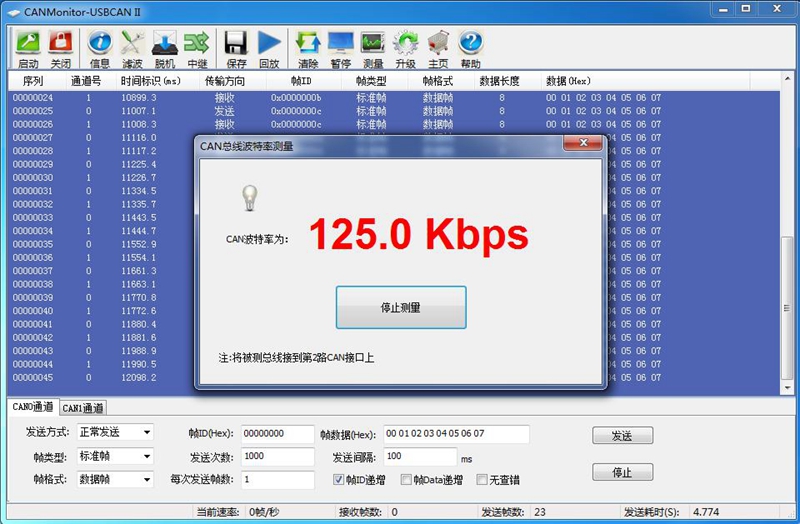

CAN Baud Rate Automatic Recognition:

- The independently developed CAN baud rate automatic recognition software can help users detect unknown bus baud rates.

Bus Baud Rate Measurement:

- By measuring the bit width time of CAN bus signals, the CAN bus baud rate can be quickly and efficiently calculated.

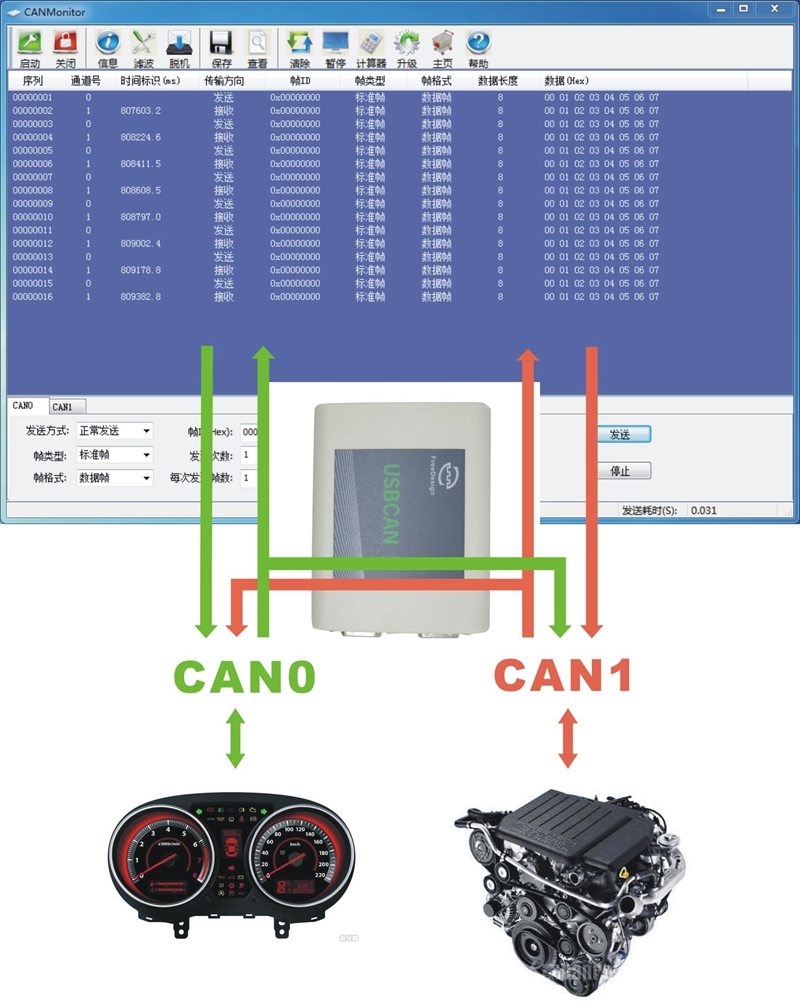

Relay Transmission:

- The relay transmission function can receive and display CAN data from the car engine and instrument panel through CAN0 and CAN1 ports respectively for protocol analysis, without disrupting the mutual communication between the two.

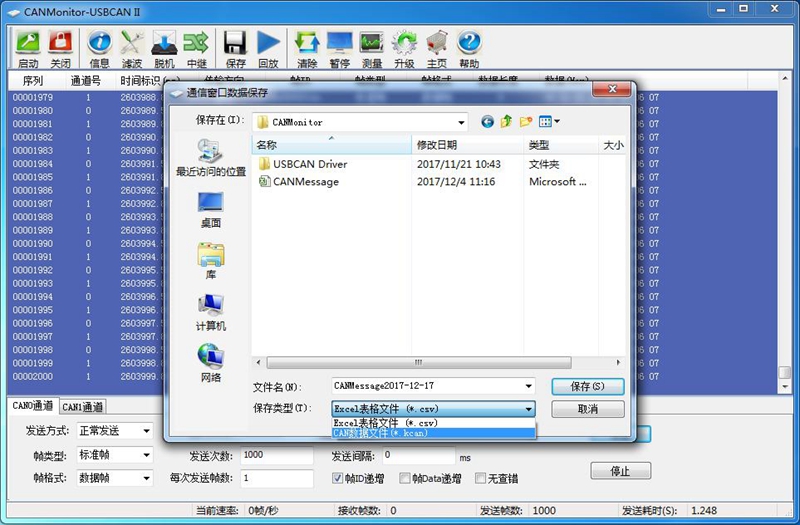

Save CAN Data Files:

- The CAN information in the window can be saved as an EXCEL spreadsheet file or a CAN data format file, which can be used for online playback and offline transmission.

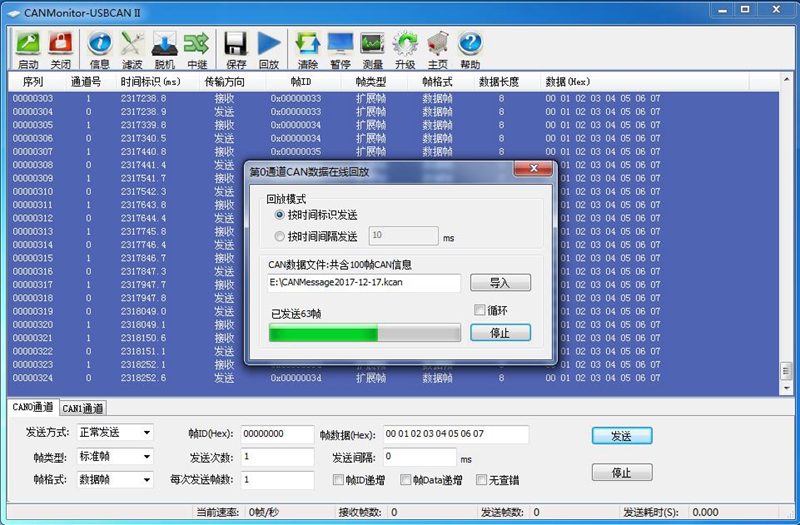

Online CAN Data Playback:

- Import CAN format data files, select playback mode: by time label or time interval, choose whether to loop playback according to requirements, and click send for online data playback.

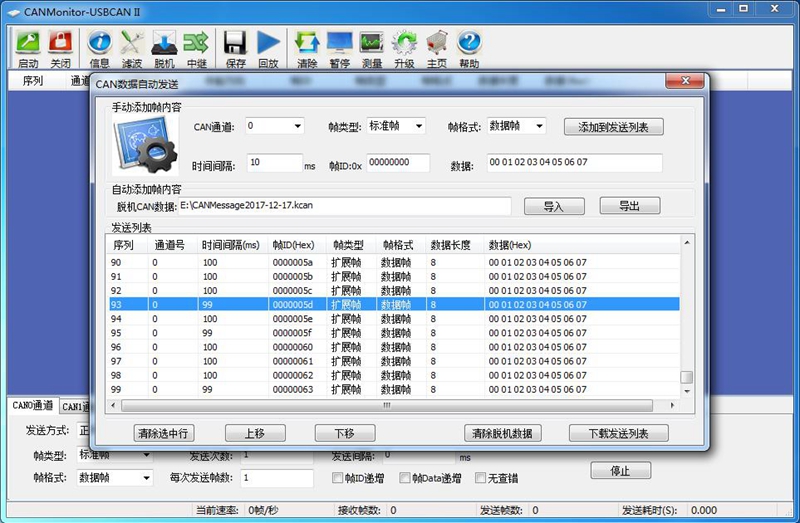

Offline Cyclic Sending:

- CAN frames and corresponding transmission intervals can be configured on the computer, or pre saved CAN format files can be imported into a window and downloaded to USBCAN for offline automatic transmission, used to simulate CAN data from some sensors or GPS receivers.

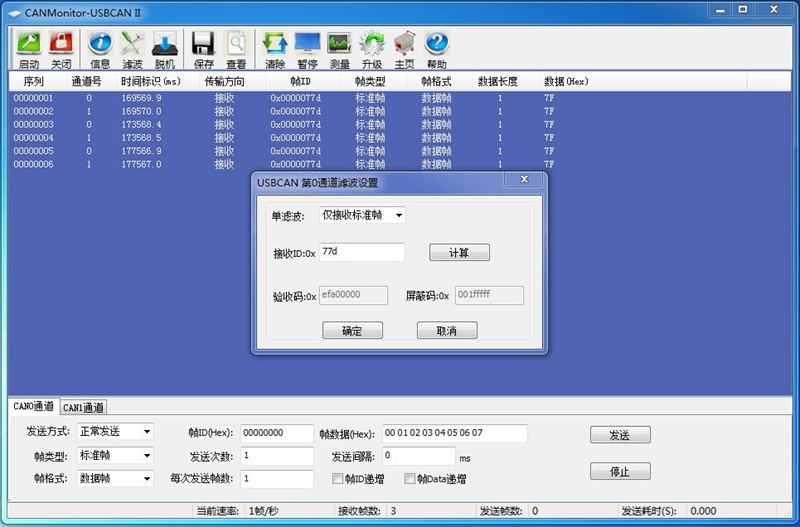

ID Filtering Settings:

- Write the ID to be received into the editing box, click to calculate the acceptance code and shielding code settings, and then click confirm to complete the settings.