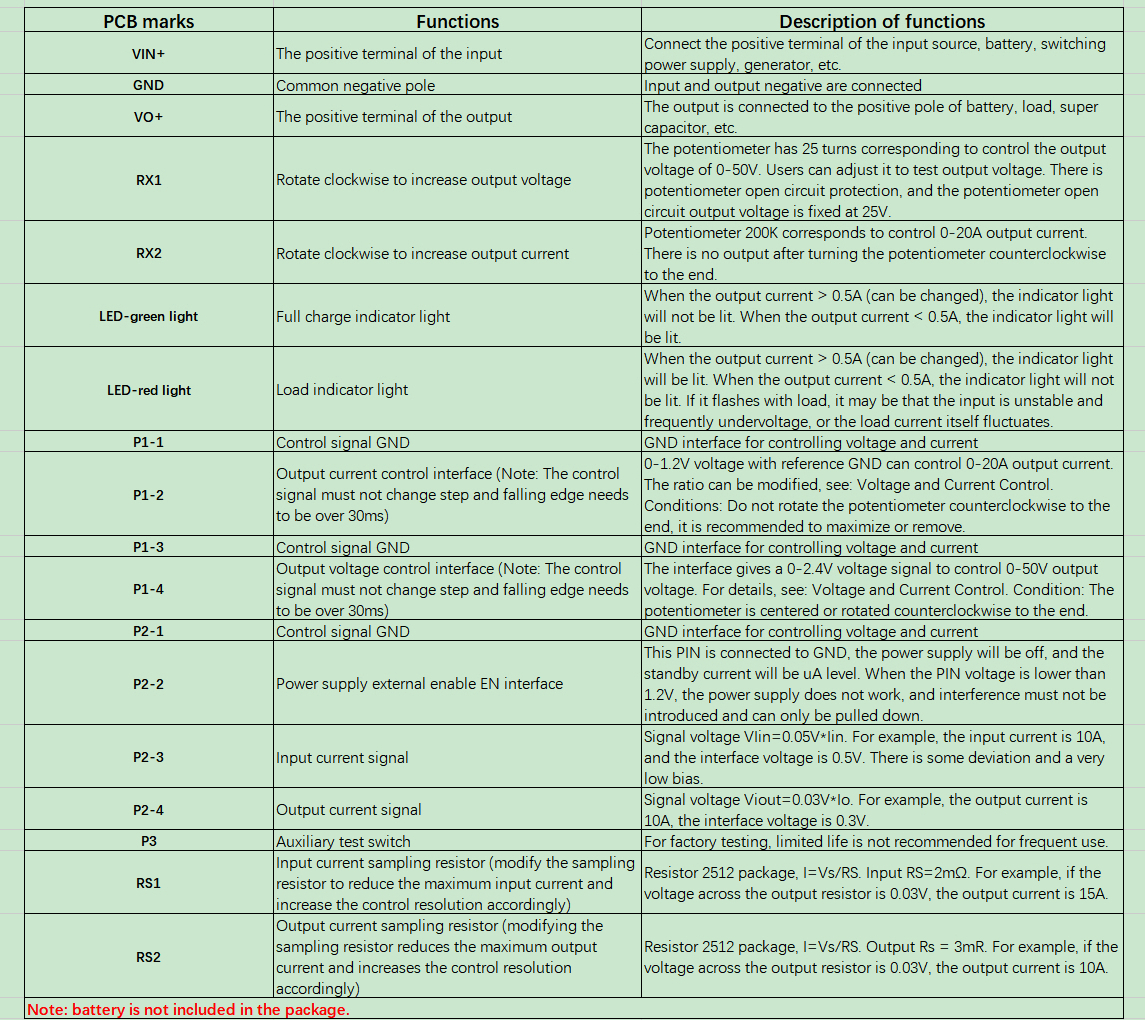

| Quantity | 3+ units | 10+ units | 30+ units | 50+ units | More |

|---|---|---|---|---|---|

| Price /Unit | $46.25 | $45.30 | $43.89 | $42.00 | Contact US |

Secondhand Imported UP19K-50L-H5 Laser Power Energy Meter 90W/15J Rang & Software Display for GENTEC

$538.14

Secondhand Imported UP19K-50L-H5 Laser Power Energy Meter 90W/15J Rang & Software Display for GENTEC

$538.14

F999M Portable Professional Leakage Detector for Water Pipes/Heating Pipes/Fire Hoses Leakage Detection

$498.30

F999M Portable Professional Leakage Detector for Water Pipes/Heating Pipes/Fire Hoses Leakage Detection

$498.30

F999K Portable Leakage Detector for Water Pipes/Heating Pipes/Fire Hoses Leakage Detection with Pointer Spectrum Display

$342.83

F999K Portable Leakage Detector for Water Pipes/Heating Pipes/Fire Hoses Leakage Detection with Pointer Spectrum Display

$342.83

YF-BKT050V15A 0.5-15A/3-52V Step up down Converter Buck Boost Converter Board with Heat Sink

Read before purchasing:

- Do not use a 3A/5A regulated DC power supply as an input to test the power supply.

- Basic technical knowledge and hands-on ability are highly recommended.

- Users need to modify parameters such as undervoltage protection parameters. We can tell you how to modify it.

-

The power supply is very stable and can be used for 5000h on the

average without failure. Factors, such as reverse connection, water

ingress, corrosion, over-voltage, over-temperature and control

modification errors will get it damaged.

- Certain power supply test

and measurement capabilities and equipment are recommended. Do not test

this power supply with a 3A adjustable regulated power supply used in

labs.

- Do not test the current-limiting power supply in CC mode of an electronic load.

-

Output current adjustment range: If the input power is sufficient, and

the output power supply is 20V and a 0.4Ω resistor is connected to

adjust CC potentiometer, the output current can be adjusted to a maximum

of 20A, but cannot be adjusted to the minimum limit value (except 0A).

Features:

- Ultra-cost-effective buck-boost power supply

- Stable performance, high efficiency and small size

- Designed with aluminum substrate

Package Included:

- 1 x Power supply board with heat sink

Note:

- Battery is not included.

Typical Performance:

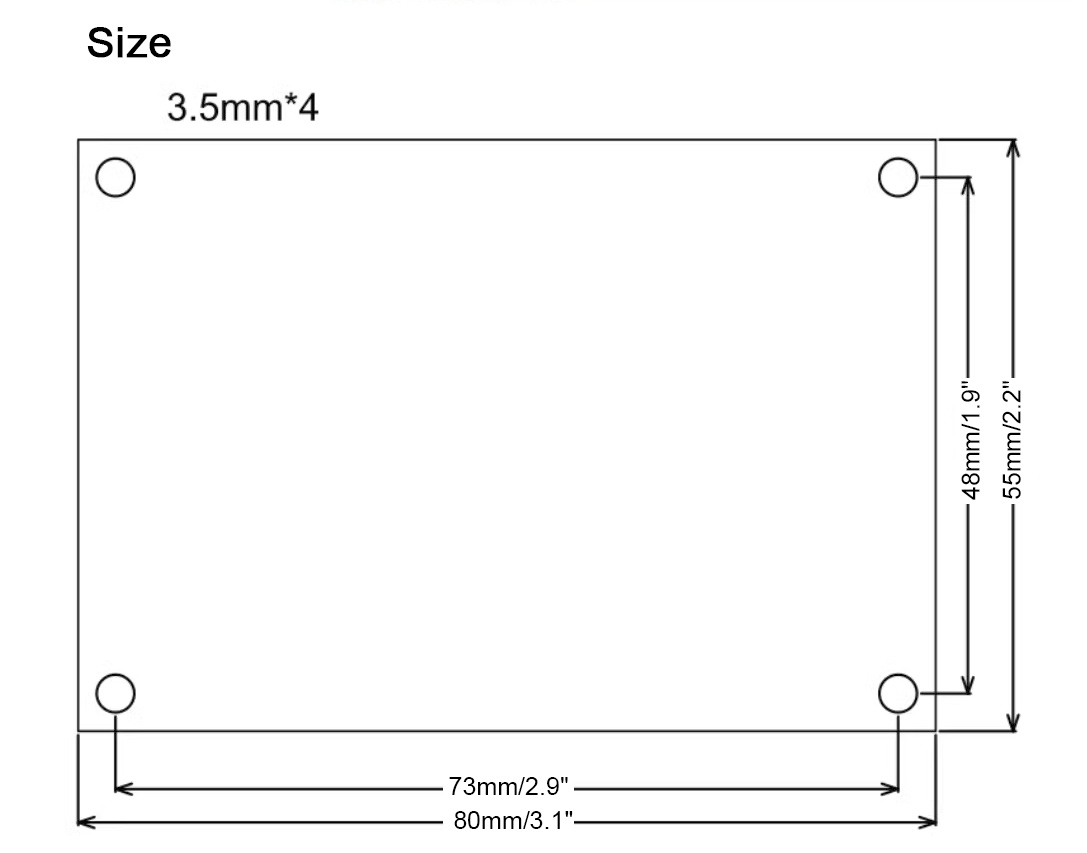

- Non-isolated four-switch synchronous buck-boost

- Wide input DC10-52V, output DC3-50V

- Peak efficiency >98.5%

- Input over-voltage, output short-circuit protection self-recovery

- Reverse protection (input fuse)

- Over-temperature protection, remote ON/OFF

- Input and output current signal interface

- Output voltage, current control interface

- Accurate and stable output current regulation

- Battery charge back-charge protection to 53V

- Super capacitor 0V voltage constant current charging

- With load indicator light, shutdown input and output are completely disconnected

- Low quiescent current, fast dynamic response, and power can be over 500W (input and output> 36V)

- Aluminum substrate, high thermal conductivity, 90°C normal operation

-

All tests are made at 24V input voltage, resistive load, and 25°C room

temperature. Parameters are subject to change without notice

Attention:

1:

Please calculate whether the maximum load is suitable according to

Iout=VIN*Iin*(0.92-0.98)/Vout. The parameter range should be within the

value of the table. Iin (max) = 20A is suitable for all parameter

calculations. For example, Vin=12V, Vout=24V, Iout=10A. Vin=48V,

Vout=24V, then Iout can be more than 15A.

2: The ripple current of

the boost output capacitor is large, and the ripple current of the

step-down input capacitor is large, which reduces the capacitor heating

and prolongs the life. Electrolytic capacitors can be connected in

parallel.

3: Can be directly connected to battery for charging. It is

recommended to adjust the output voltage correctly before connecting

the target battery.

4: The slow startup time and EN enable together

to control the delay time. When the start-up time of the input source is

long, you need to adjust the slow startup time of the output. For

example, the AC adaptation output full-load voltage settling time is

50ms, while the power supply startup time is 2ms, which may cause AC to

fail to start properly with load.

5: Users with dynamic response

requirements can optimize specifically. For example, the output is

connected to sensitive devices such as a host computer.

6: Some parameters may be adjusted for different applications.

Attention:

1:

When testing this power supply, it must be ensured that the input

source can provide a large enough current (>25A) to ensure that the

power supply does not collapse or even be damaged, especially when

starting with load. When the live test is performed, the negative

electrode is connected first, and then connect the positive electrode.

When shutting down, disconnect the positive terminal first.

2: The

startup time of the input source must be less than the startup time of

this power supply (e.g. adapter as input), otherwise it may not be

possible to start with load.

3: The input wire connected to this

power supply shall not be too long (the internal resistance of the wire

shall not be too large), otherwise the power supply may cause

oscillation and abnormality.

4: If there is a diode in series with

the input source to this power supply, the power supply may be damaged

by the surge voltage caused by instantaneous on-off (line BOOST effect).

5:

Do not use the CC mode of an electronic load as the load of this power

supply. It is recommended to use the CR mode. CC mode draws current,

this power supply is current limited, and in constant current mode, this

will cause the power supply to crash.

6: It is recommended to

connect adjustable output voltage with a resistive load (dummy load)

with small current, to ensure the real-time adjustment of output voltage

potentiometer. Otherwise, the output voltage will change slowly and the

regulation will be inaccurate.

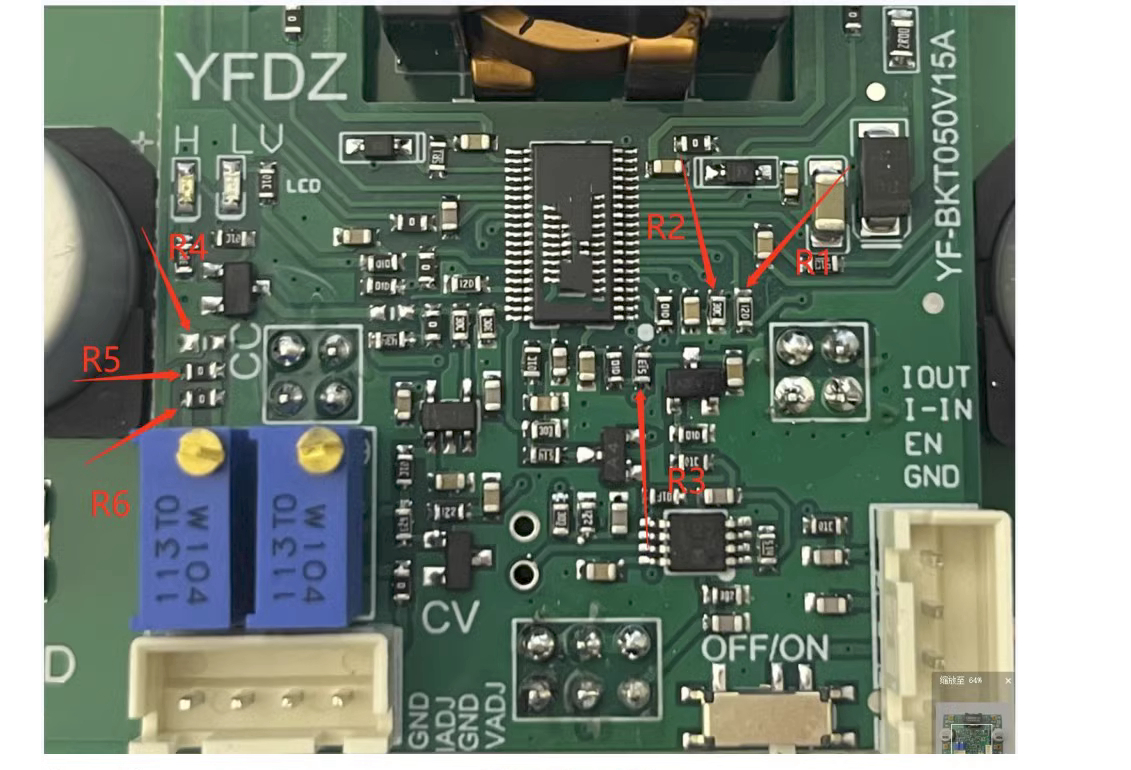

Modify input undervoltage protection value:

The

default undervoltage protection value is V=(R1/R2+1)*1.2=9.0V (R1=130K,

R2=20K). By modifying the two resistor values, you can modify the input

undervoltage protection value. Note: Undervoltage protection must have a

hysteresis range, which cannot be changed. The input current and the

diameter of the wire affect the protection value. It is recommended to

set the value a little lower.

Voltage and Current Control:

1:

Voltage control Vo=52.8-21.5*Vx. Vx is the voltage of the external

control signal (0-2.4V), and the voltage control signal must not have

step change, otherwise it may cause permanent damage to the board.

2:

Current control: Iout=Vi/0.06. Vi is the external control signal

voltage (0-1.2V). For example, if the no-load signal is 0.6V, the output

current is limited to 10A ± 0.3A. It is recommended to correct the

scale.

If the load capacity of the control signal is not enough,

R3 can be removed. R6 can be completely externally controlled. Without

giving a control signal, there will be no output. If the ratio cannot

reach 0-1.2V, R3 and R6 can be removed.

R5 and R4 are divided by

voltage, for example, R5=80K, R4=20K, then the control signal becomes

0-6V corresponding to controlling output current of 0-20A (amplified by 5

times)

Attention: Step change is not allowed for the control signal, otherwise it may cause permanent damage to the board.

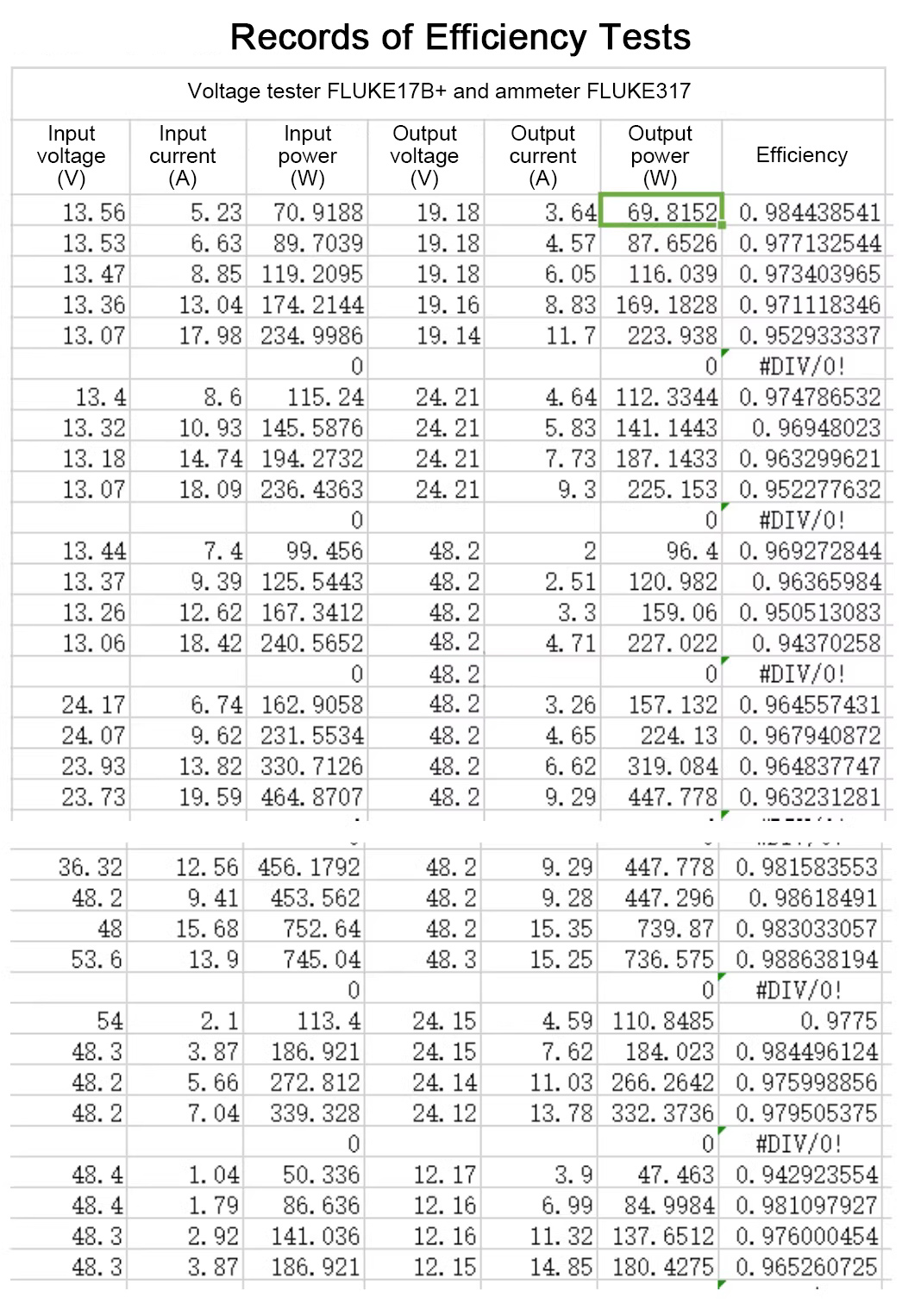

The

above efficiency data is the actual test value, and the efficiency

range is 94.2-98.8%. You can refer to the above data to estimate the

efficiency of your own application parameters.