| Quantity | 3+ units | 10+ units | 30+ units | 50+ units | More |

|---|---|---|---|---|---|

| Price /Unit | $2,430.71 | $2,381.11 | $2,306.70 | $2,207.48 | Contact US |

XSB9 Handheld Force Gauge Digital Force Gauge + DYMH-103 Miniature Load Cell Sensor (0-200KG)

$168.45

XSB9 Handheld Force Gauge Digital Force Gauge + DYMH-103 Miniature Load Cell Sensor (0-200KG)

$168.45

XSB9 Handheld Force Gauge Digital Force Gauge + DYMH-103 Miniature Load Cell Sensor (0-100KG)

$168.45

XSB9 Handheld Force Gauge Digital Force Gauge + DYMH-103 Miniature Load Cell Sensor (0-100KG)

$168.45

XSB9 Handheld Force Gauge Digital Force Gauge + DYMH-103 Miniature Load Cell Sensor (0-50KG)

$157.09

XSB9 Handheld Force Gauge Digital Force Gauge + DYMH-103 Miniature Load Cell Sensor (0-50KG)

$157.09

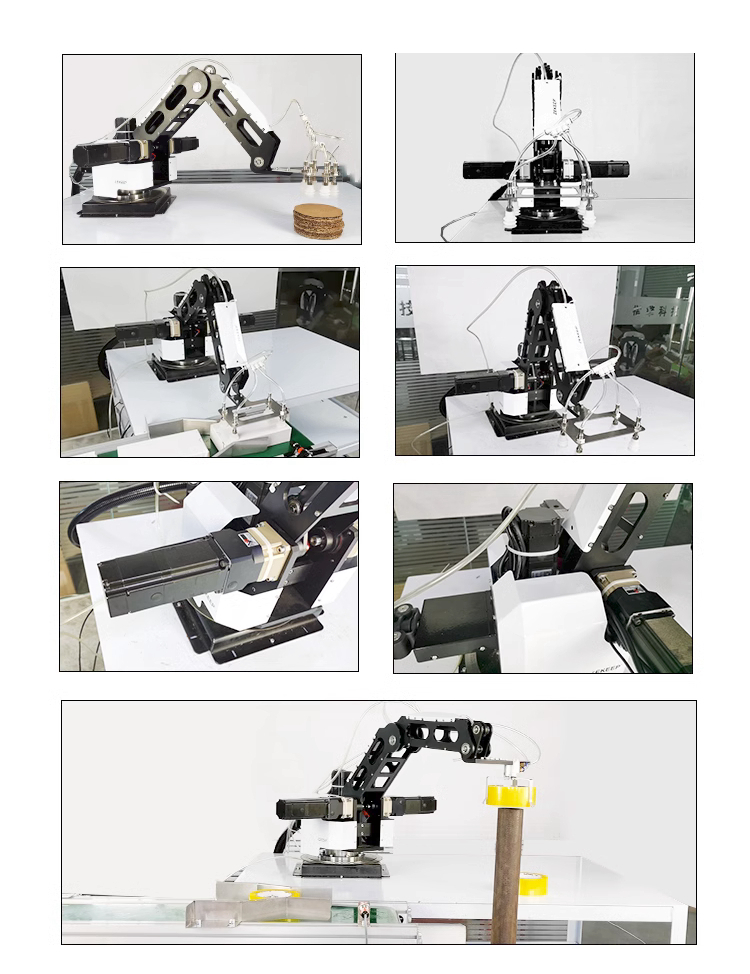

ZEKEEP 3-Axis Small-Sized Industrial Robot Arm Mechanical Arm Robotic Arm w/ 5KG/11LB Load Capacity

Advantages:

- Intelligent handling

- Multiple ways for unstacking and stacking

- Two teaching programming methods

- Accurate accuracy

- Open movement protocol

- Support secondary development to meet various industrial control linkages

Functions:

Stacking, unstacking, handling, loading and unloading functions

- 8 types of pallets can be used. The number of palletizing and handling times can be set in the cycle setting, which can be set according to the needs of industrial production.

- Pallet number and palletizing sequence can be selected via its demonstrator.

- Support 6 palletized cargo arrangements (cargo placement direction).

Palletizing interface

- Speed is adjustable. It can display position coordinates, display palletizing and handling times, record work cycles, etc.

Two teaching programming methods for easy operation of the robot

- Support jogging teaching programming. This robot refers to the programming habits and interface design of large industrial robotic arms. In industrial use, in order to improve stability and avoid data transmission interference loss and delay, it is not recommended to use APP wireless control or computer software and other control methods.

- Support drag teaching programming. You can drag the robotic arm movement by hand and it can record the trajectory, trajectory and position. It can also be fine-tuned through the touch screen, and input and output IO can also be used to complete complex programming. It is easy to use and control for customers who do not have a programming foundation.

Draw a square on a flat surface

- It can follow the trajectory of a square and draw a square.

Multi-segment arc drawing

- It can move and draw arcs according to the trajectory of the arc.

Support IO input and output control and multi-machine online work with a production line

- There are 6 input and 6 output IOs, which support external signal IO input to trigger the control of the robot, or robot IO output signal to trigger the control of external devices.

8 major work instruction operations, precise coordinates, speed settings, etc.

- When selected, the instruction set selection box will turn gray, and the point command is the walking point. The joint offset is the offset relative to the current coordinates. An arc is a circle. Both straight lines and line offsets are straight lines (the former is an absolute position and the latter is a relative position). DI/DO is an IO input and output port (each with eight interfaces). The palletizing function is handling.

Touch screen demonstrator

- Real-time display of coordinate position and speed for each step.

- Device alarm logs: The alarm record records all alarm entries for the last seven days, including the time and date

- User program settings: 3 groups of user fixed programs can be saved, which is convenient for using multiple working modes. With power-off storage function.

- Equipment daily inspection test procedure: Three test procedures are available.

Features:

- Rigorous structural design and premium materials. The design of the base structure has been patented. Robotic arm, motors, reducers, bearings and various spare parts are custom designed.

- Use joint coordinates and world coordinates. Position accuracy can be set. The position can be adjusted via the teach pendant touch screen. It is designed according to the way of industrial robots.

- Anti-lost step function: If an external force collides and the robotic arm loses its steps, it will automatically return to its position to ensure the accurate movement position during work.

- With brake: When the power is off, the robotic arm can remain in its original state. In the event of a power outage or power loss, this device will not be destroyed.

- A variety of alarm prompts and settings ensure the stability and security of the equipment. Single-step speed (zero error alarm), motor failure alarm, motor communication fault alarm, joint offset error alarm, minimum ring speed error alarm, deceleration position error alarm, circulation body out of range alarm, emergency stop alarm, etc.

- The display of the teach pendant indicates the reason for the alarm

- Its control box has an indicator light

Specifications:

Basic parameters:

- Number of axes: 3 axes

- Working voltage: 220V 50HZ

- Power supply input: 24V/14.6A

- Operating temperature: -10 to 60°C

- Materials: Body: Aluminum alloy. Base: sheet metal weighted. Control box: sheet metal

- Machine weight (including robot arm and control box): 30KG/66.1LB

- Output power: Over 150W

Load parameters:

- Maximum load: 5kg/11lb

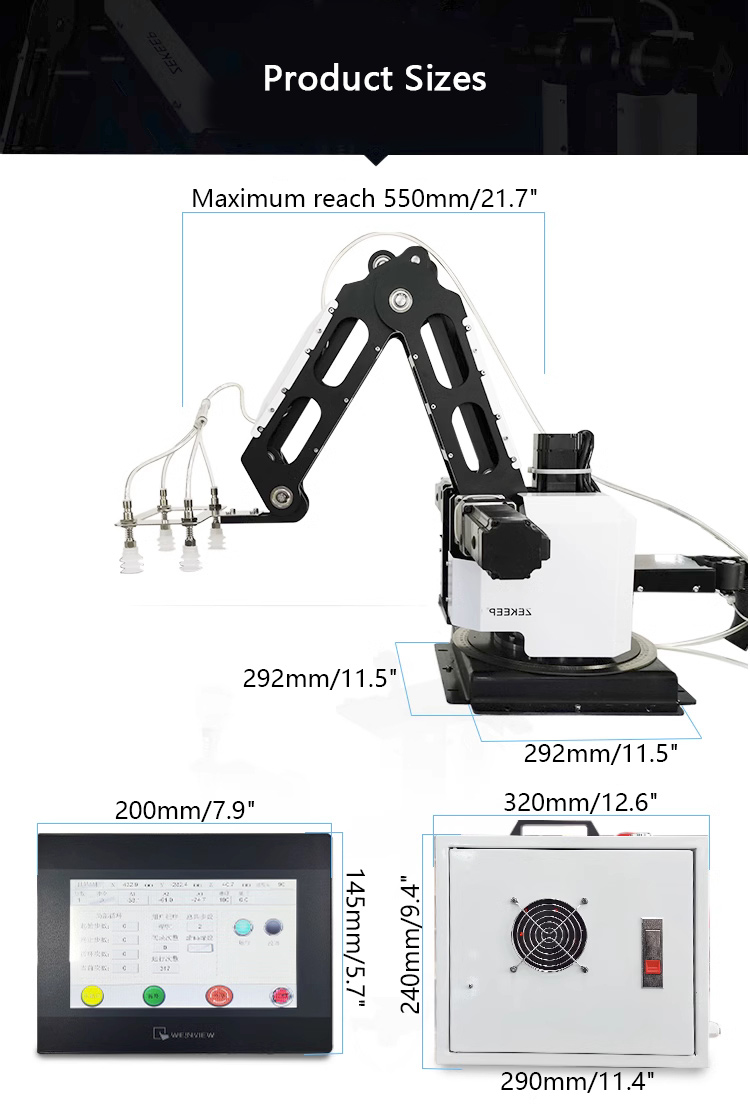

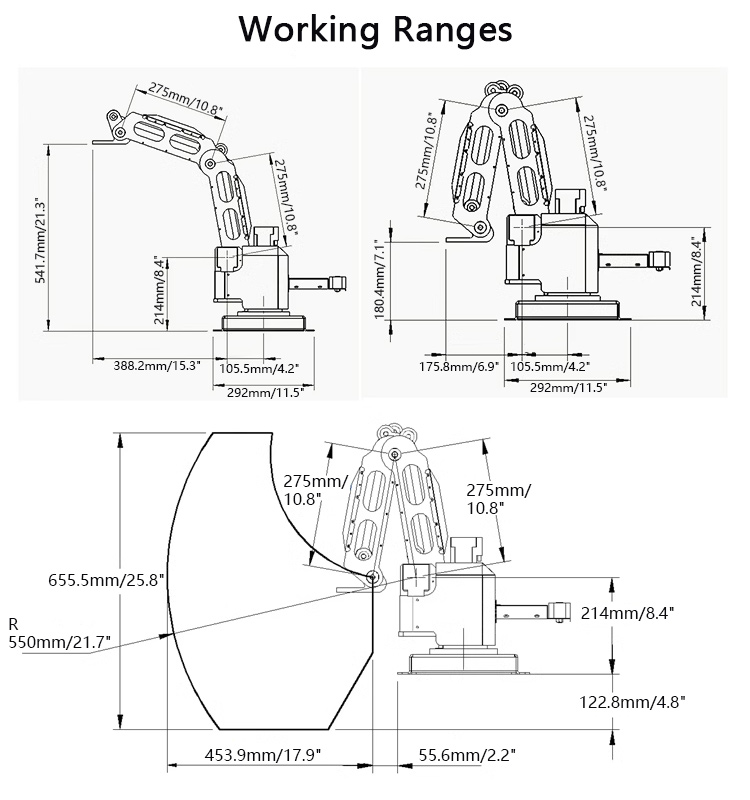

Working ranges:

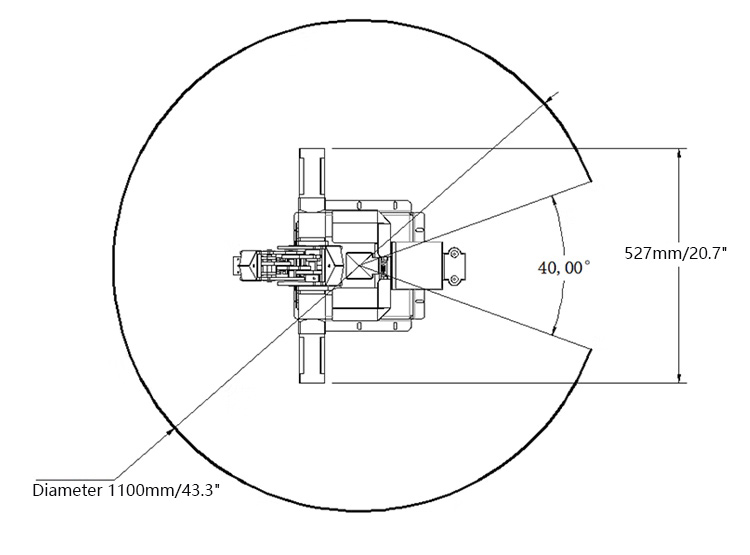

- Base rotation working range (X-axis): -162° to 162° (dead zone reserved 36°)

- Upper arm working range (Y-axis): -100° to 0°

- Forearm working range (Z-axis): -118° to 0°

- Maximum reach: 550mm/21.7"

Motion speed parameters:

- Maximum speed of single arm joint: 300°/s

Accuracy parameters:

- Repeatability: 0.3mm/0.01"

Motor parameters:

- Type: 57 closed-loop stepper motor (with encoder and brake)

- Step angle: 1.8°

- Holding torque: 3N/m

- Rated current: 5A

Speed reducer parameters:

- Type: High precision helical teeth (not ordinary straight teeth)

- Backlash: less than 3 arc minutes

Functional parameters:

- Linear interpolation, circular interpolation, acceleration and deceleration algorithm, and input and output IO

Control mode parameters:

- Jog teaching programming: The programming method is similar to that of large industrial robots

- Drag teaching programming: drag by hand, teach pendant records position and enables position fine-tuning

Package Included:

- 1 x Robotic Arm

- 1 x Touch Screen Demonstrator

- 1 x 2M/6.6FT Connection Cable (to connect the robot arm to a control box)

- 1 x Control Box

Note:

- Electronic user manual is provided.

- End effectors such as clamps and suction cups are not included.

- Other items pictured are not included, for demonstration purposes only. Thank you for your understanding!